When it comes to turbo motors, I think maybe Ben Franklin said it best in his “Poor Richard’s Almanac.”

The honey is sweet but the bee has a sting!

The takeaway from Big Ben’s statement is that we shouldn’t let something good tempt us because there is always a price to pay!

***

Okay, so maybe Mr. Franklin was more interested in kite flying than turbo LS motors, but the sticky and the stings are no less relevant today. We all love boost, especially when it comes from a turbo, but there is (as always) a negative side to positive pressure. One of the unfortunate laws of physics is that heat is a natural byproduct of compression. All that wonderful boost causes unwanted heat, and heat is the enemy of both power and longevity. We love the boost but hate the byproduct, so what is an enthusiast to do?

The answer is obviously intercooling, but let’s take a closer look not just at intercooling, but at the actual changes in charge temperatures and power generated during a recent test on intercooling (a de-stroked LS3 no less!).

Understanding How Intercoolers Work

Before getting to the test, we should take a brief look at intercooling. We mentioned that the boost pressure supplied by forced induction heats the inlet air and that heated inlet air is bad for both power and safety. The cure to increased charge temps caused by boost is intercooling. Intercoolers involve running the heated charge air through a heat exchanger.

The two most common types of intercooling include air-to-air and air-to-water heat exchangers. The air-to-air intercoolers rely on increased surface area and ambient airflow through the core to lower the charge temperature, while air-to-water cores rely on water as the cooling medium. This discussion is not about which one is more efficient, as the choice will come down to the specific application.

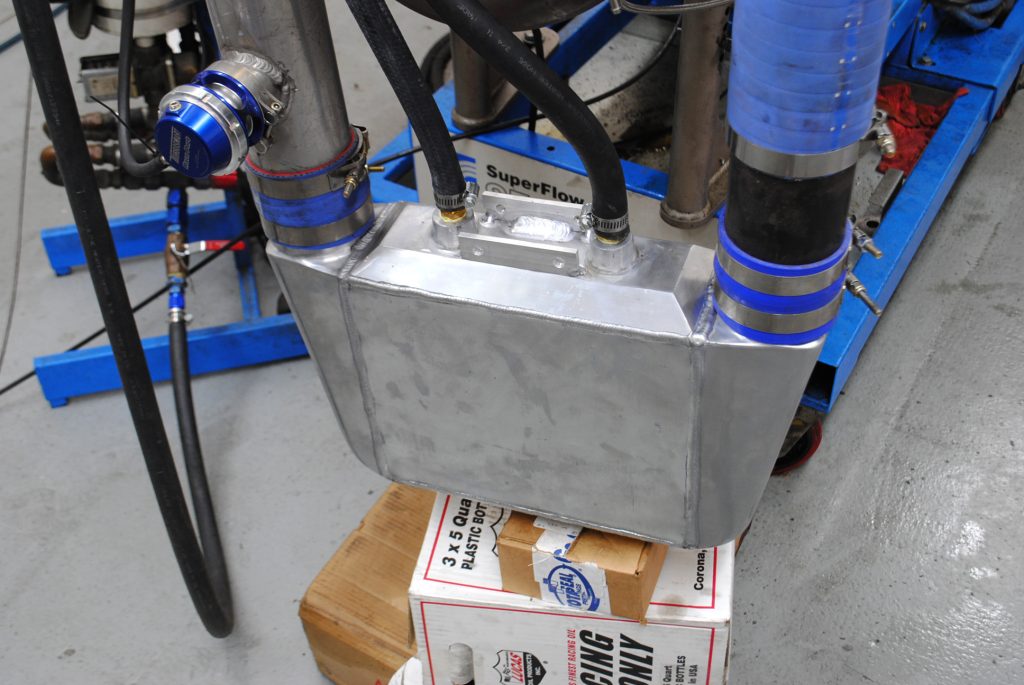

For our test, we ran an air-to-water core from CX Racing with and without water flowing. As the data will illustrate, the mere fact that we had a core, even with no water flow, meant that some cooling took place, but the system was not nearly as effective as had cooling water been flowing freely.

The Intercooler Test Engine

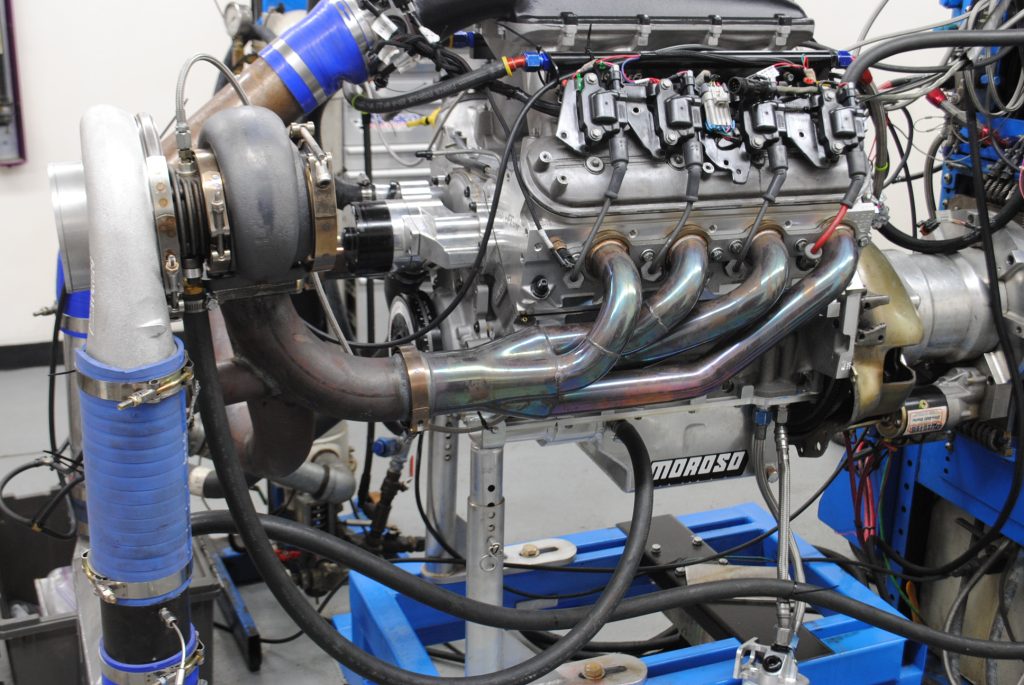

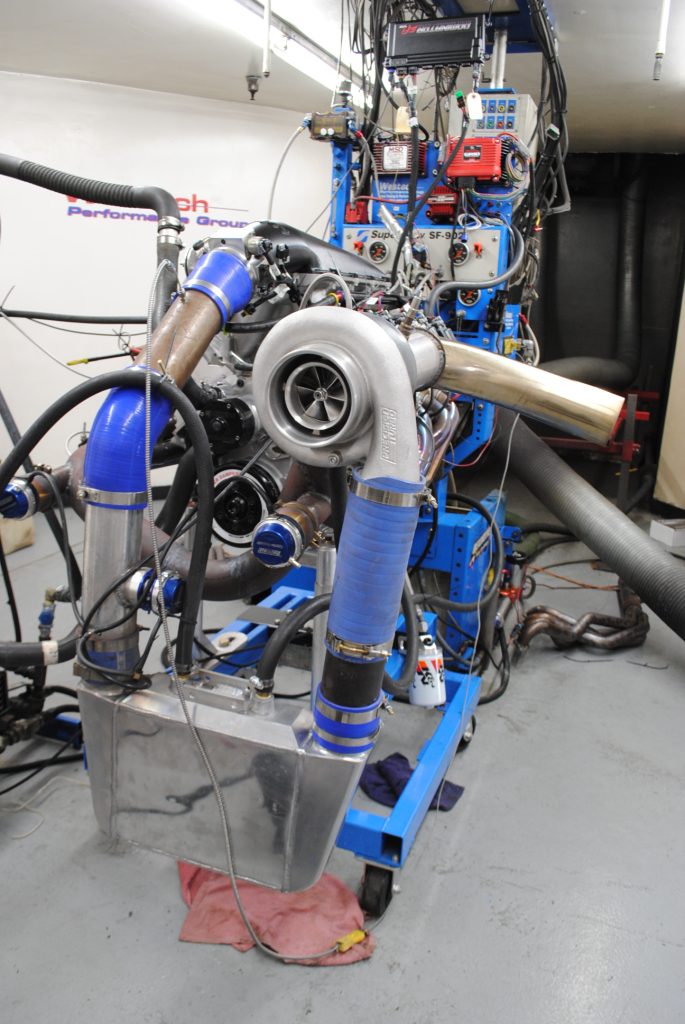

To test the effect of the cooling water, we had to set up a turbo motor. Luckily we had just such an animal at our disposal in the form of a short stroke LS3 engine.

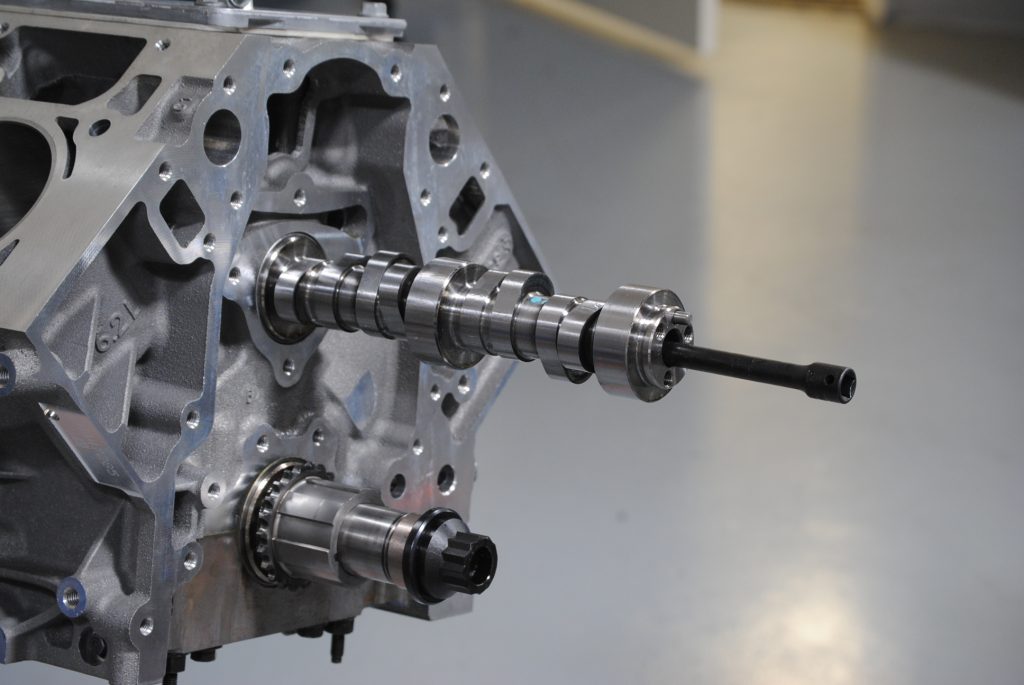

The LS3 block from Gandrud Chevrolet was stuffed with a 4.8L crank, 6.30 inch Lunati rods and custom JE forged pistons. The LS3 short block was filled with a Stage 2 turbo cam from Brian Tooley Racing then topped with a set of Trick Flow GenX 255 cylinder heads and Holley Hi-Ram induction system.

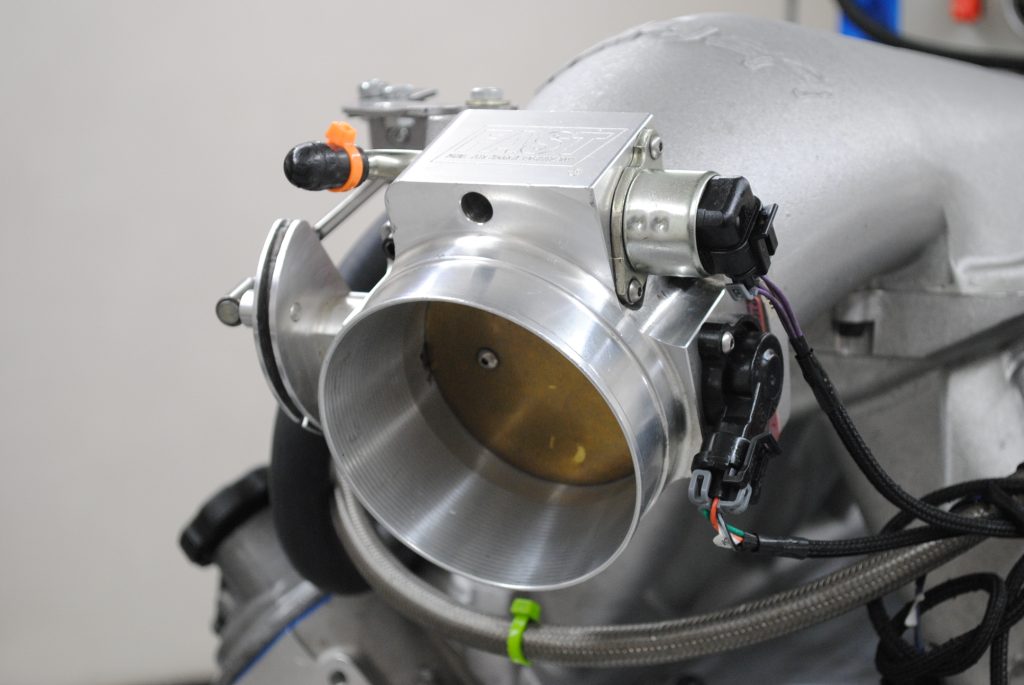

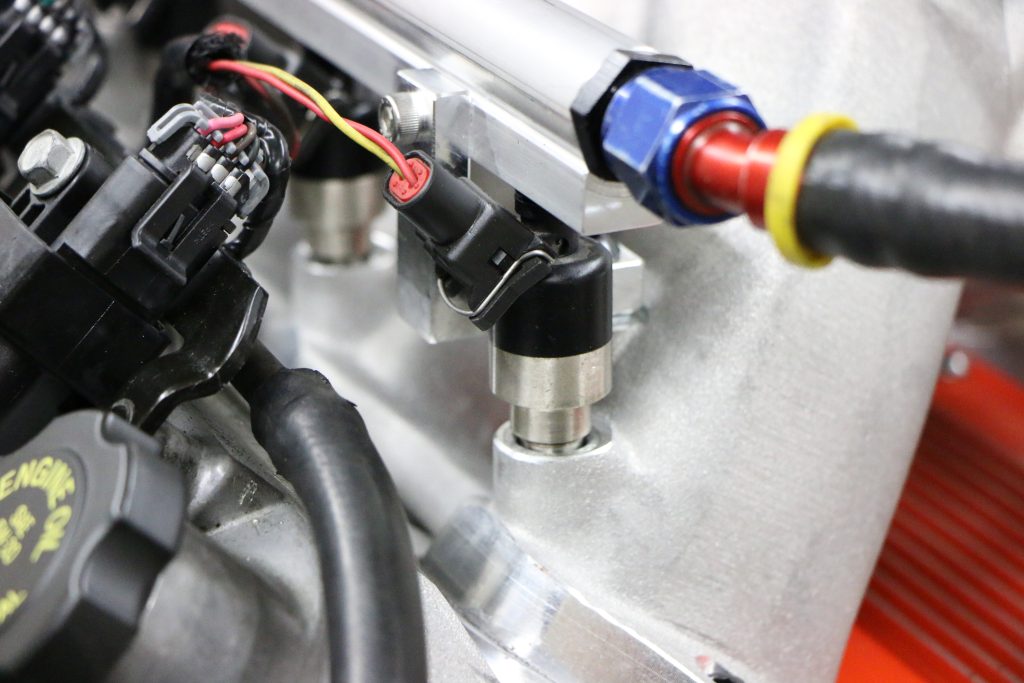

Airflow came via a FAST 102mm throttle body while fuel was supplied by a set of Holley 83-pound injectors controlled by a Dominator EFI system.

The single turbo system was a homemade affair consisting of a pair of tubular manifolds from DNA Motoring feeding a custom Y-pipe. The T4 turbo flange fed a 76mm Precision turbo controlled by a pair of 45mm Hyper-Gates from Turbosmart (set to seven psi).

The test revolved around an air-to-water intercooler supplied by CX Racing that featured 3.5 inch inlets and outlets. The core relied on a single water inlet and single water outlet, allowing us to manually shut off the supply of 83 degree dyno water to the core. We monitored the air temps both before and after the intercooler as well as with and without the water flow.

Testing Intercooler Performance

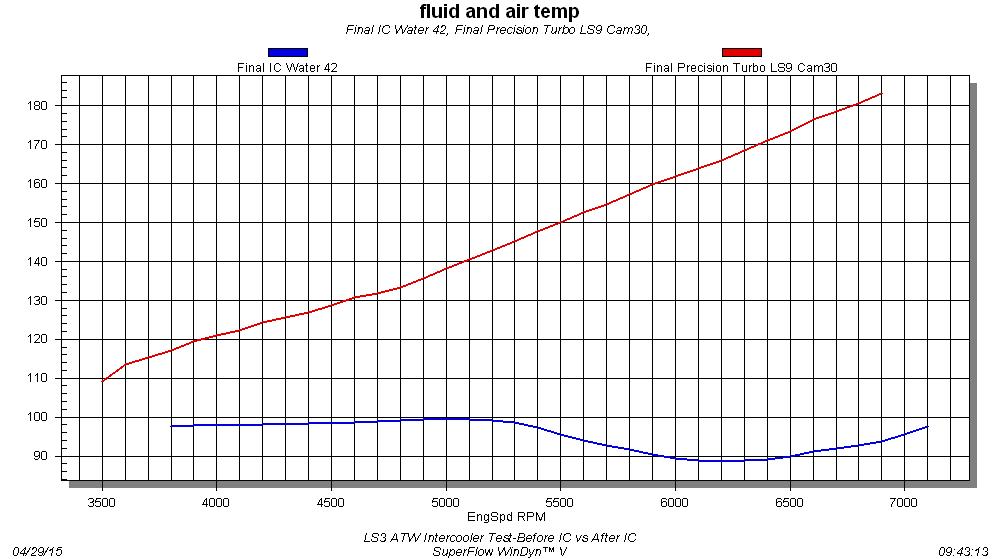

The first test was to turn the turbo motor with the intercooler functioning properly with full water flow through the core. The waste gates were set with seven psi springs, which resulted in a maximum boost level of 7.4 psi. Running 7.4 psi resulted in a rising charge temp exiting the turbo. During the run, the inlet air temp exiting the turbo rose from 109 degrees to 183 degrees.

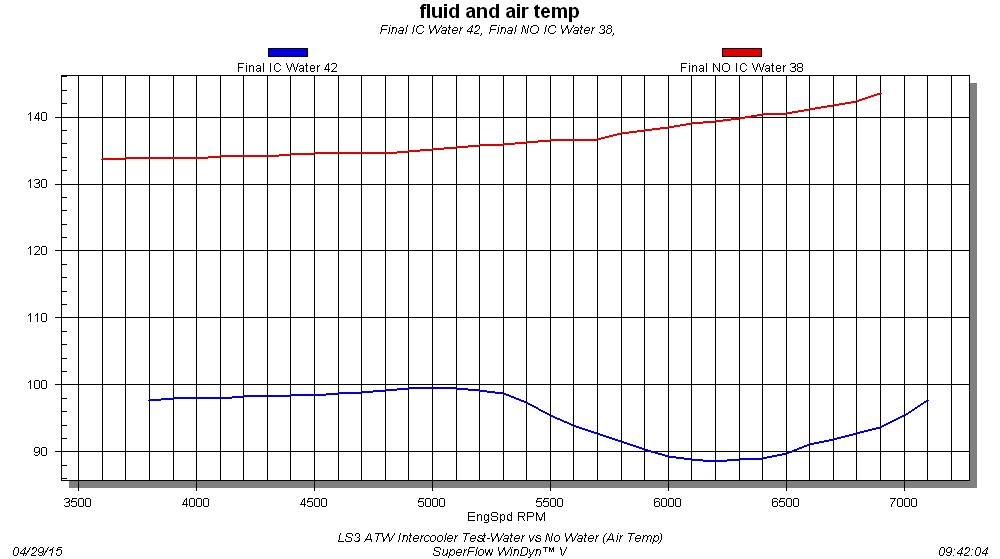

Using 83 degree dyno water as the cooling medium, the air temps exiting the intercooler never exceeded 98 degrees and actually dropped down to 90 degrees during the run (see graph 3). Even at the relatively low boost of 7.4 psi, the inlet air temp rose to 183 degrees and that was with a steady supply of ambient air to the turbo, which might not be the case under the hood. The intercooler was on the job, reducing the charge temps by almost 90 degrees!

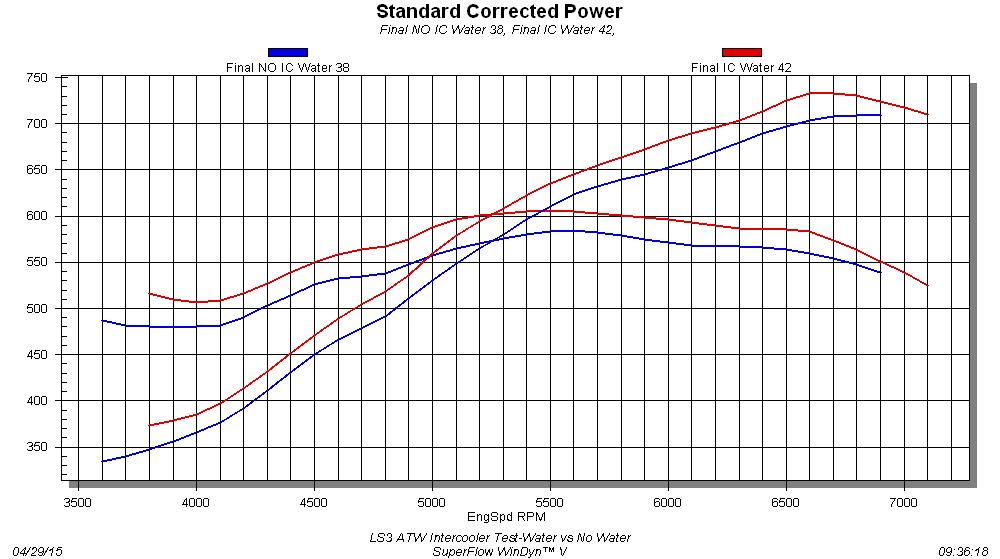

The results were quite different after shutting off the water flow to the core, as the inlet air temps (after the intercooler) started higher at 134 degrees and rose to 144 degrees. This was 46 degrees higher than the air temp with water flow. The result was not just hotter air (which can cause harmful detonation), but a loss in power from 733 hp to 706 hp.

Note: No changes were made to timing based on the IATs (timing remained constant).

These results are proof positive that the best medicine to lower the air temps and make more power is the one and only chill pill!

my god you are running a liquid to air cooler with no liquid inside a closed aluminum core housing??? There is not even heat transfer from ambient air at this point. What would you expect it to do?????

There was still liquid (dyno water) inside the intercooler housing, it was just not flowing in/out, so the water and intercooler core essentially served as a large heat sink—albeit a poor one, as the test indicated.