We rebuilt a new 5.3L LS engine for our 1954 Chevy truck with a 4L60E automatic behind it. We added a performance cam and had the oil pan off to clean the engine and check everything and add new gaskets.

Once we had the engine in the truck and running the converter, the front pump seal failed right away within less than 100 miles. The transmission was used so we figured it was just a bad seal. We replaced the front pump seal but within another 100 miles it started leaking again. We’ve looked it over and can’t figure out what we’re doing wrong.

We don’t want to just put another seal in it—obviously there’s a problem. Any ideas?

J.F.

We might have offered a host of ideas around this, but luckily (or unluckily), this has happened to a friend of ours who was struggling with a very similar problem.

There are potentially other issues here but we will focus on the one that we discovered with our friend’s transmission in a 2007 Chevrolet Tahoe with a 5.3L LS engine and 4L60E transmission.

Understanding the LS Oil Pan Design

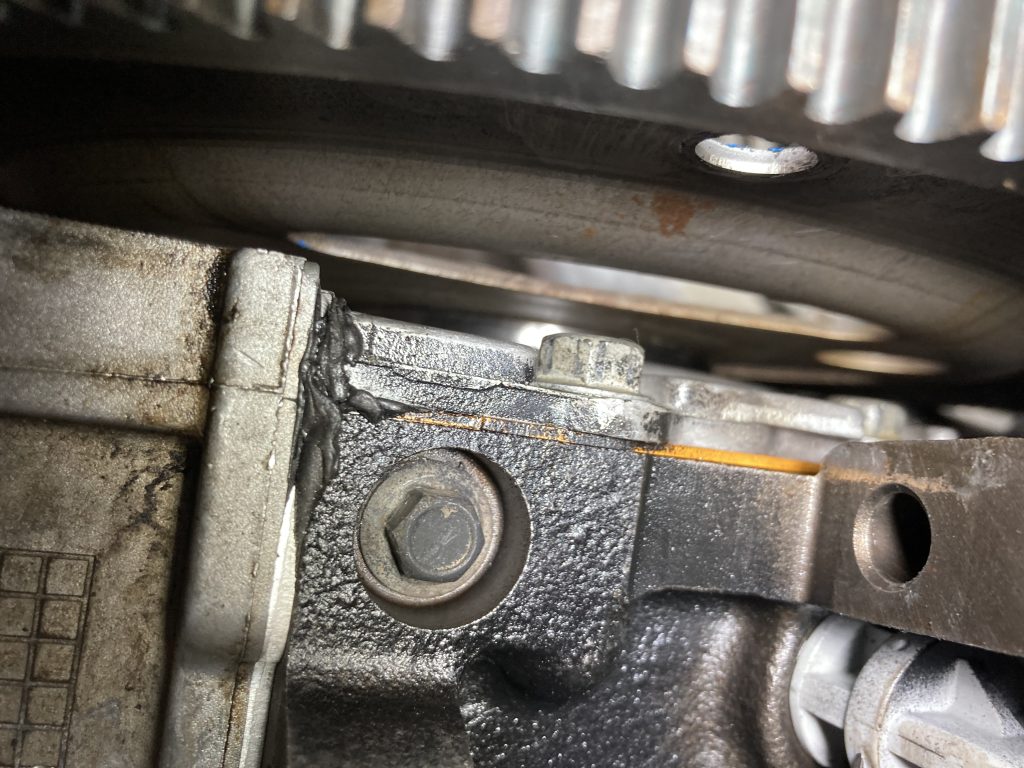

In order for this to make sense, you need to know that when GM designed the LS engine, they integrated the cast aluminum pan as part of the entire drivetrain package. What that means is that, at the bottom of the oil pan, GM included two threaded bolt holes in the oil pan where the bottom of the full face bellhousing bolts to the pan. GM did this to improve the strength of the connection between the transmission and the engine.

This is critical to what often happens with changes to these engines and transmissions. The issue lies with proper alignment of the oil pan with the back of the engine. The LS engines are not fitted with dowel or alignment pins to position the front or rear cam covers, nor are there dowel pins for the oil pan.

All these components essentially “float” on or around the block’s oil pan rail.

It’s very easy to position the oil pan slightly rearward of the vertical bellhousing flange on the LS engines. If this occurs and the transmission is bolted to the engine, this slight misalignment of the rear vertical pan face to the transmission bellhousing will tilt or cock the lower portion of the bellhousing rearward. If the pan is misaligned far enough rearward, it will impart a load on the front of the transmission which will create a lateral load on the transmission input shaft through the converter.

What happens is the converter and crankshaft are no longer properly aligned and this misalignment can put a lateral load on the converter which will fail the front pump bushing and seal very quickly.

Checking & Fixing the Leaky Transmission Seal

One way to check this is to remove the transmission and place a small block Chevy style manual transmission bellhousing on the back of the engine and see if the cast aluminum oil pan pushes the bellhousing face rearward. In our friend’s situation, the bellhousing actually rocked vertically around the alignment dowels that told us the oil pan was too far rearward. You may see this as a gap between the bellhousing and engine’s bellhousing mounting surface.

The fix for this is simple. You will have to loosen all the oil pan bolts and pry the oil pan forward enough to relocate it to be as close to parallel with the bellhousing flange as possible.

This will allow the automatic transmission bellhousing flange to then align properly to the engine. If the oil pan is mounted too far forward, the opposite but equally problematic issue will occur where this again puts a load on the converter seal because the trans is not vertically aligned. This makes oil pan placement very important.

Of course, if you are using an aftermarket steel or aluminum sheetmetal LS oil pan, this won’t be an issue. But when using even an aftermarket oil pan like the Holley cast aluminum LS oil pan, these pans are machined for the lower bellhousing bolts and the pan must be properly aligned or the problem will surface again and again..

Comments