We started our race engine after it sat all winter and the engine started running rough. We discovered a pushrod hat had punched right up through the pushrod cup. I’ve never seen this before. I run a small block Chevy in a circle track class that requires stock, stamped steel rockers so I can’t just swap them for a roller rocker. Is there something wrong with the rocker geometry or was this just a bad rocker, or is there something more that we don’t know? Thanks for your help.

B.P.

We’ve seen this before on stock rockers and there’s an easy way to prevent this from re-occurring or at least minimize this from happening again. Stock stamped steel rockers use a small hole for lubrication. This hole is often poorly drilled (or more likely punched) through the pushrod cup. Often this technique leaves a sharp edge on the top side and we’ve seen most rockers with a jagged tip protruding from the top side of the pushrod hole.

These sharp edges are classic places for a stress riser or a crack to form because the load from the valvespring is concentrated in this very small area. Once a crack forms, it does not take long for the pushrod to open this up and the pushrod will punch right through.

The fix is easy. Remove all the rockers from the engine and use a die grinder or rotary tool with a small stone and grind off the flashing around the top side of the pushrod oil hole. Remember to wear safety glasses. This process is usually sufficient to smooth the area to prevent forming a stress riser. You can polish this area if you want. This will instantly make all the rocker arms stronger. It’s a simple task that will improve rocker durability.

Other Potential Precautions

I would also recommend using the pivot balls with integrated lubrication grooves. The exhaust rockers tend to run hotter than the intakes so using these rocker balls is especially important on the exhaust side. Along that same line, if you will be replacing rockers, put used intake rockers on the exhaust side since they are already broken in and will operate cooler.

Another item would be to use a short poly lock instead of those locking rocker nuts. The stock locking nuts tend to tear up the threads on rocker studs. If you have not done so and it is a legal modification, I would recommend converting to pushrod guide plates and screw-in ARP rocker studs. The ARP rocker studs are centerless ground and will be much more consistent than other machined screw-in studs. We’ve seen cheap studs that are not straight that can produce an offset of 0.020 inch or more which will change the relationship of the rocker to the valve and alter valve lift.

Testing & Checking Rocker Arm Ratio

Since you are racing I would heartily recommend this next effort. Find a cast-off cylinder head and create a test stand for checking rocker ratio. Add a light checking spring to one valve and create a valve lift limiter over the valve stem that will stop valve lift at 0.250 inch. This is an arbitrary number—you can choose any lift but we chose this as the half-lift point..

Stabilize the head so it doesn’t move and place a dial indicator on the top of the pushrod hole that you just polished. Make sure the dial indicator is parallel with pushrod travel and depress the spring retainer until it stops against the limiter. Make sure this process is repeatable. Now record the dial indicator reading. If the rocker is a true 1.5:1 ratio with a valve travel of 0.250 inch, the indicator should show pushrod travel of 1.666 inches.

More than likely, you will not get this amount of pushrod travel. Instead the dial indicator will probably read higher than 0.1666 inch which means the rocker is generating a ratio multiplier of less than 1.5:1. For example, if the dial indicator reads 0.169 (0.003 inch more travel) then the ratio is closer to 1.48:1. We’ve done this test with 32 stock GM rocker arms and discovered a whole pile of rockers at 1.48:1 and not a single one at 1.50:1. We did see a few rockers that were 1.51:1.

Keep in mind that this test is only valid for this valve lift. Since a rocker arm travels in an arc across the valve stem, the ratio changes as the rocker arm tip moves across the valve stem. If you want, you can test again at full valve lift and see how much the ratio changes. I did not do this part of the test but likely rockers with a low ratio at half lift will also offer a low ratio at full lift.

Pushrod Length

Changing pushrod length is another way to affect the rocker tip travel across the valve stem and stabilize the lift curve. If you want to experiment with this, you can blue the top of the valve tip and change the pushrod length by 0.025-inch and see what happens to the rocker travel across the valve stem tip. The goal would be a shorter path across the valve tip, which should improve valve lift consistency.

In our test many years ago, we couldn’t find enough 1.51:1 ratio rockers to form a complete set but we did have 8 so we used these on the intake side with a set of 1.48:1 rockers on the exhaust side. We never dyno tested this package but we did notice that the engine idle improved by one full inch of manifold vacuum and we attributed this to a more consistent rocker ratio on the intake side.

You might have to check 32 or 48 (or more) rockers to find a complete set with the same rocker ratio (even if it is only 1.49:1 for example) but I think it might be worth the effort. Opening and closing all the valves at the same time will contribute to a happier engine and it might make a little more power on top of all that.

You might also experiment with putting the higher ratio rockers on the exhaust side. We’ve seen mild small blocks respond with more power when adding rocker ratio to the exhaust side as opposed to the intake side. Of course, we’ve also seen it where this additional ratio hurts power too! It all depends upon your combination.

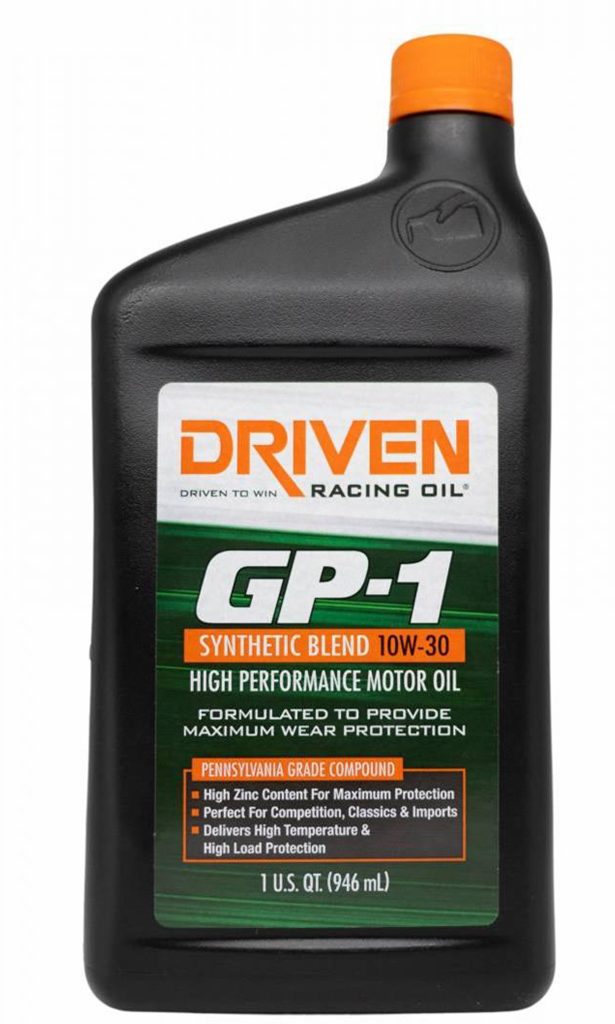

I’ve looked at a couple of IMCA circle track motors that have to run stock rockers and I would also highly recommend using a full synthetic or at least a synthetic blend engine oil. Synthetics are more stable at higher operating temperatures and that rocker arm ball on the exhaust side gets very hot. For example, Driven GP-1 engine oil is a synthetic blend that can do the job much better than a typical off the shelf AP SN rated oil. Plus, GP-1 contains a higher ZDDP additive count compared to off-the-shelf oil that will enhance engine life. There are other racing oils as well that would do the job and this is worthy of consideration

A cooler running rocker arm will last much longer than one that runs hot. Don’t restrict the oil to the top of your engine. If anything, look at valve cover drippers that will direct additional oil on the rocker balls to help them keep cool.

Hope this helps!

Parts List

- Summit Racing stamped steel rocker arm kit – SUM-G6800

- Melling grooved rocker balls – MEL-MRM-1731

Comments