When it comes to making power, look no further than boost: Boost is your friend, boost is your buddy, boost will come pick you up when your car breaks down.

Okay, maybe not the last one, but when it comes to making more power, it’s tough to beat boost!

Adding boost to any combination can result in serious power gains, but as with anything, there is more than one way to skin the proverbial performance cat. For some, the less-is-more route is attractive, where you combine a small, milder (less) motor with higher (more) boost. Of course, the engine combination should be built to withstand the extra power, but that is an easy fix. These combinations usually involve low compression and milder cam timing, both of which allow for elevated boost levels.

Others favor the opposite more-is-less route, where they combine an already powerful normally aspirated (more) combo with just a hint of (meaning less) boost. Basically, this is a healthy normally aspirated combination that is provided just enough boost to reach a given power output.

Not only did we test both combinations with popular superchargers, but also, just to mix things up, we further escalated this Boost Battle by applying one to a (Blue Oval) Ford and one to a (Bowtie) Chevy!

Blue Oval: Paxton Supercharged 327 Ford

Illustrating the less-is-more route was our 327 Stroker Ford. Compared to the more-is-less Chevy, this combination offered a smaller displacement, lower compression, and milder cam timing, but made up for those deficiencies with increased boost pressure.

The (relatively) small displacement, low-compression Ford featured a stout short block, capable of potentially withstanding much more boost and power than the Chevy, but we kept things mild and streetable for this test. The 327 displacement came courtesy of an A4 block from Ford Racing stuffed with a 3.20 inch Scat Stroker crank, Eagle connecting rods, and Probe forged pistons. When combined with the 60cc chambers in the Edelbrock Victor Jr. heads, the static compression checked in at 8.4:1.

To this bulletproof long block we added a Comp XE266HR cam, an Edelbrock Performer RPM Air Gap intake, and Barry Grant 750 cfm Mighty Demon carb. Also present was an MSD distributor, Hooker headers and Lucas 5w30 synthetic oil. We opted to run the motor on the dyno in naturally aspirated trim to better illustrate not just the power of the supercharged combination, but how much of each combo was motor and how much was boost.

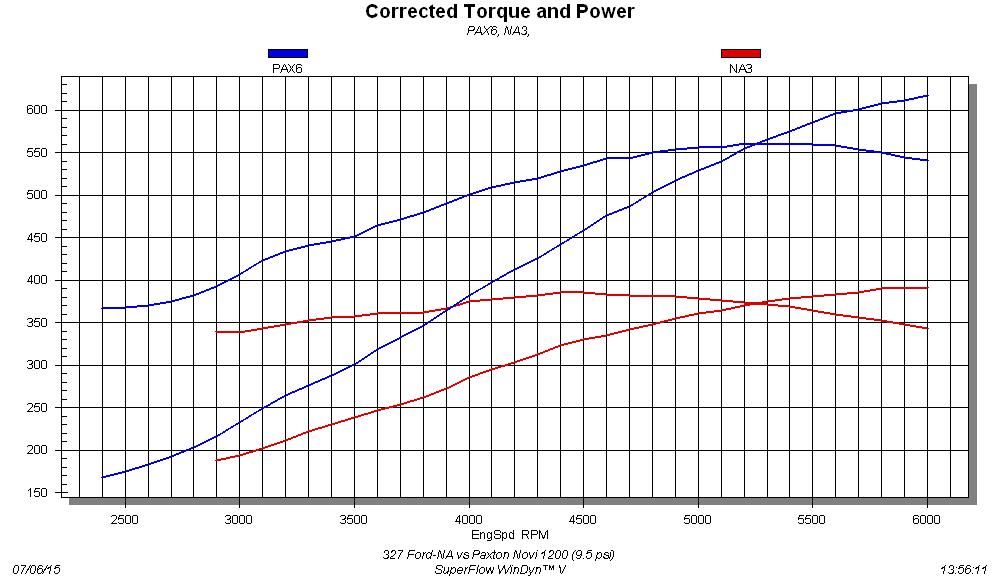

Run on the dyno in naturally aspirated trim, the low-compression 327 produced peak numbers of 392 hp at 6,000 rpm and 386 lbs.-ft. of torque at 4,400 rpm. There was certainly much more power to be had from this combo with wilder cam timing and increased compression, but the 8.4:1 327 was just literally begging for boost.

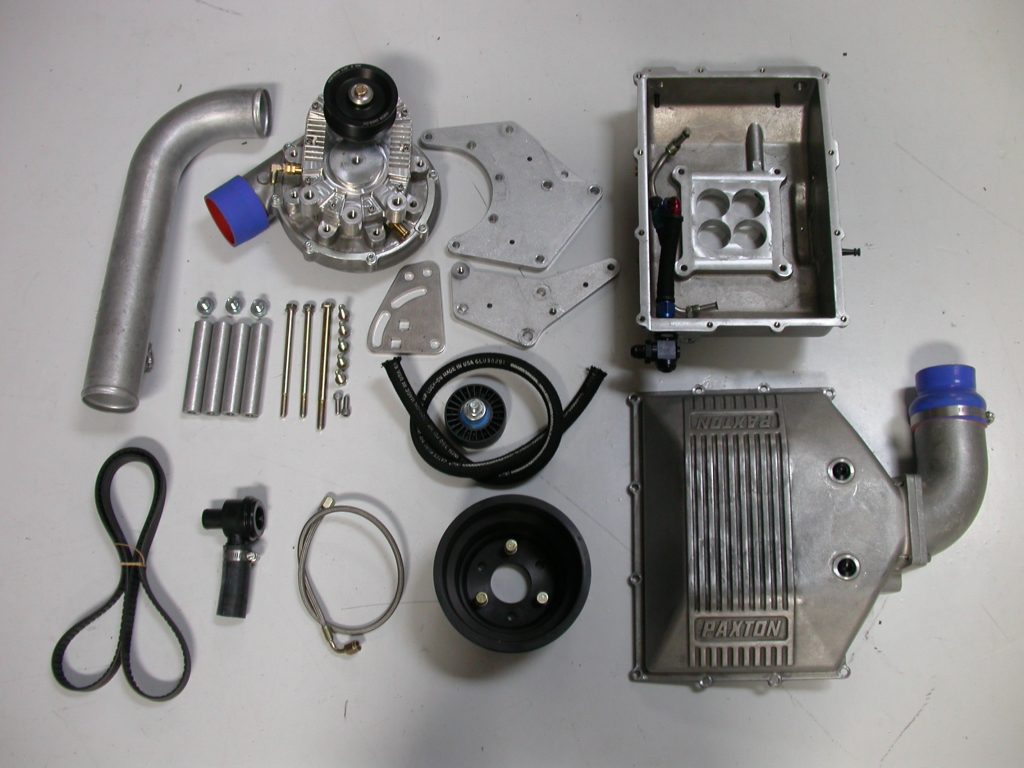

Adding some much-needed power was a complete carbureted supercharger kit from Paxton. The kit included all the mounting hardware, carburetor enclosure and powerful Novi 1200 supercharger. Knowing boost from the blower was a function of the blower speed relative to engine speed, we combined a 7.0 inch crank pulley with a 3.3 inch blower pulley. The result was a peak impeller speed that eclipsed 45,000 rpm in route to producing 9.5 psi of boost.

When we were finished with tuning, the supercharged Stroker produced 617 hp and 561 lb.-ft. of torque, though it should be pointed out that the power and boost were still climbing at our 6,000 rpm shut-off point.

The combination of low compression and the carburetor acting as an intercooler meant this less-is-more package was easily pump-gas friendly.

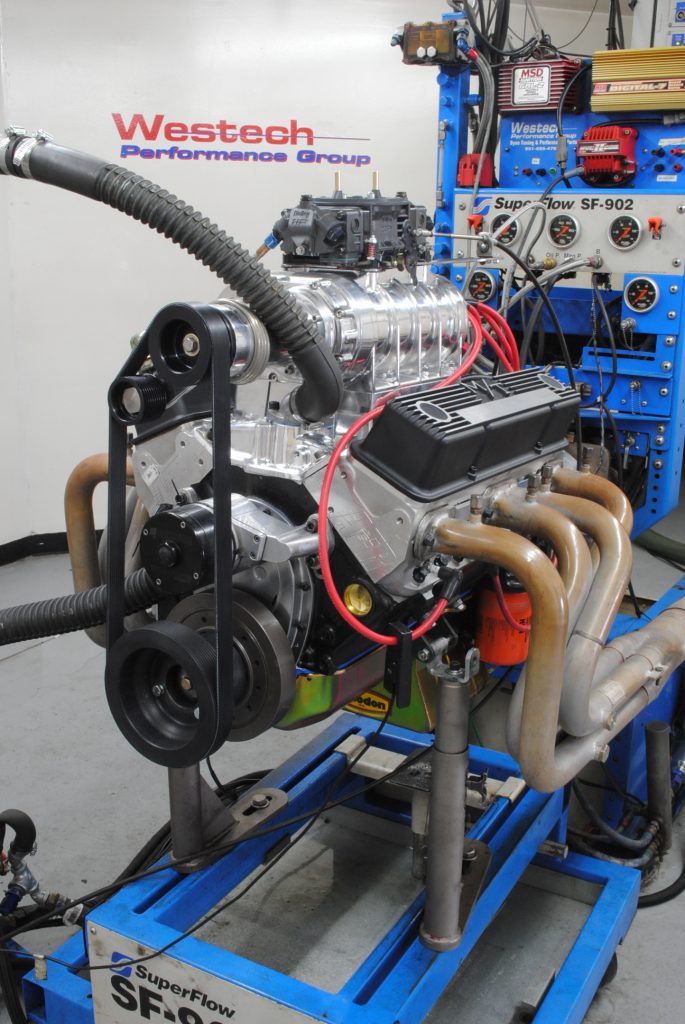

Bowtie: Weiand Supercharged 383 Chevy

Starting with a milder motor is all well and good, but our (Bowtie) Chevy took the opposite route by combining more motor with less boost.

The “more” portion of the equation came from a solid buildup that included a high(er) compression 383 Stroker.

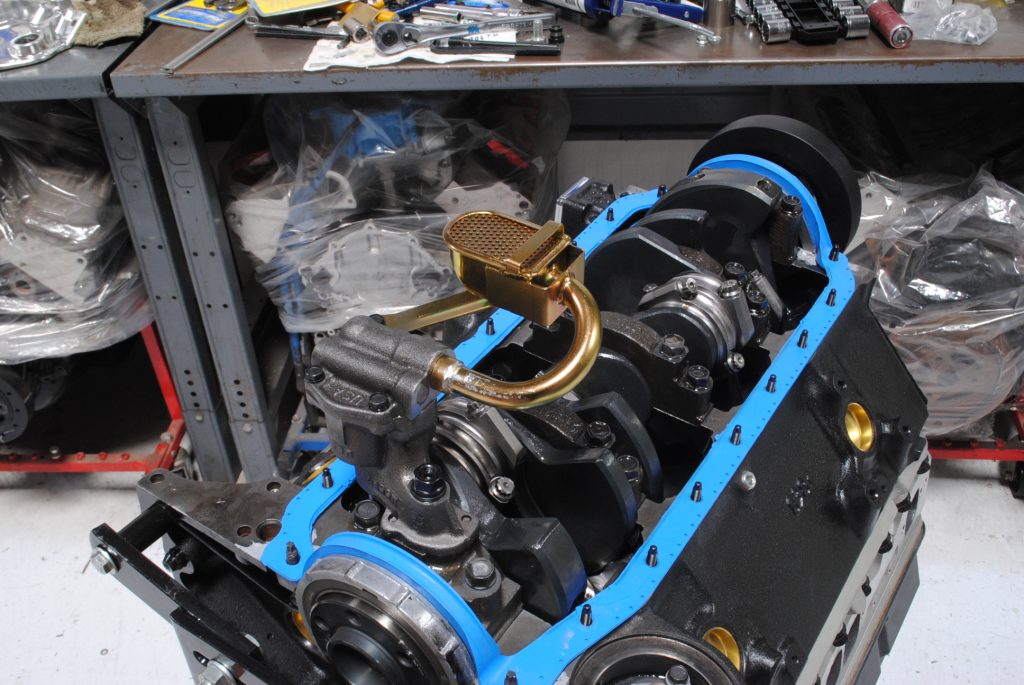

Starting with a late model, 4-bolt block, we added a Speedmaster forged 3.75 inch Stroker crank and 6.0 inch (4340) rods. The JE flat top pistons and Total Seal rings combined with the 70cc chambers offered on the AFR 210 Eliminator heads to produce a static compression ratio of 10.3:1.

Though considered high for a blower application, the aggressive cam timing, aluminum heads, and minimal boost level meant this 383 combination thrived both normally aspirated and supercharged.

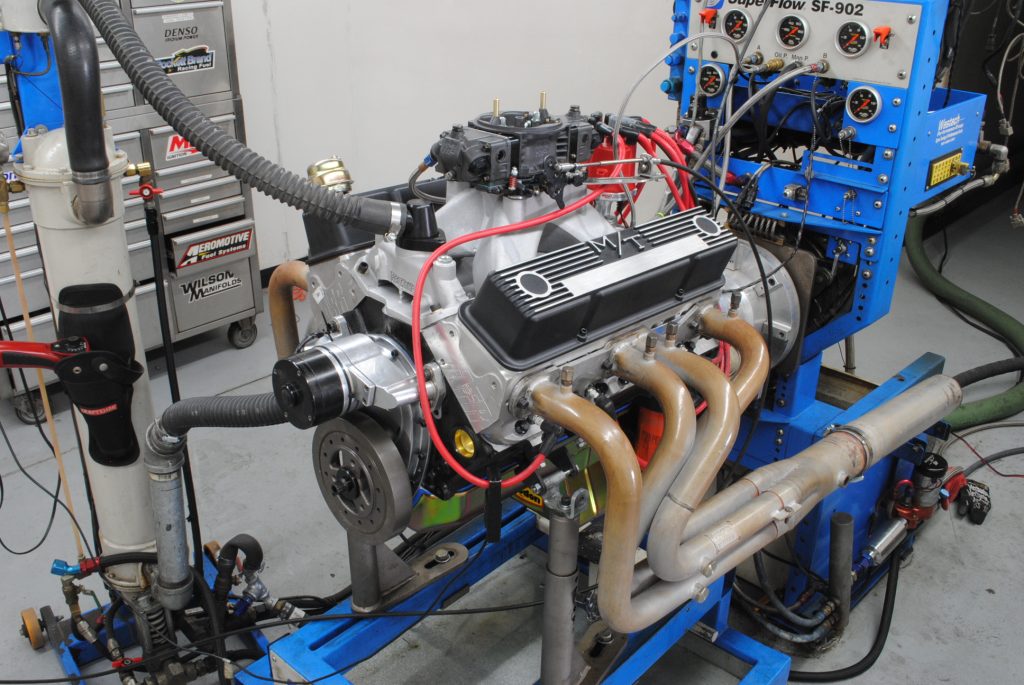

The AFR 210 Eliminator cylinder heads featured enough flow to support well over 600 hp in naturally aspirated trim, especially when combined with a Crane hydraulic roller cam that offered 0.600 lift, a 252/256 degree duration split, and tight 108 degree LSA. The finishing touches on the Stroker small block included a Speedmaster single-plane intake, 950 HP Holley carb and full MSD ignition system. As with the Ford, we ran the Chevy in naturally aspirated trim to illustrate the power gains offered by the less portion (meaning blower) of this More-is-Less combo.

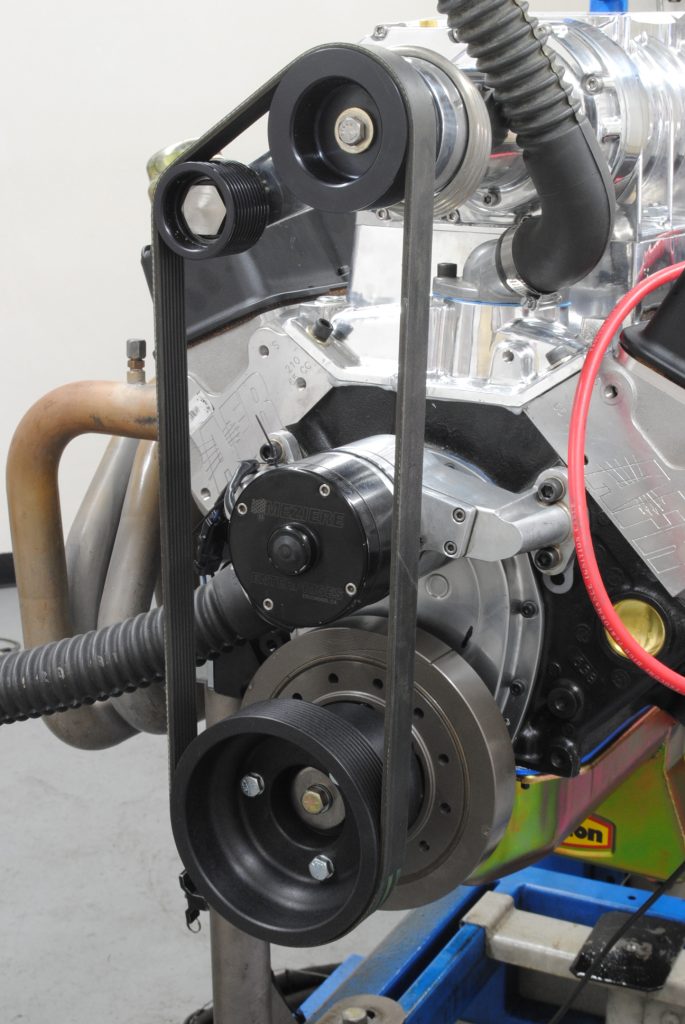

After putting the 383 on the dyno with 1-3/4 inch headers, a Meziere electric water pump, and retro Mickey Thompson valve covers, we were rewarded with impressive peak numbers of 550 hp at 6,600 rpm and 491 lb.-ft. at 5,200 rpm.

The big motor with plenty of compression, cam timing, and head flow churned out some stout numbers even before adding the blower, but now it was time for the Weiand 177 supercharger. Installation of the little Weiand blower was no more difficult than an intake swap, but you are not likely to get this kind of power gain from your average 4-barrel manifold. The 177 blower was configured with a 7.0 inch crank pulley and 3.0 inch blower pulley. Fed by a 950 HP carburetor, this combination resulted in a peak boost pressure of 6.1 psi and peak numbers of 644 hp and 565 lb.-ft. of torque.

In the end, the choice between Less-is-More and More-is-Less is more or less a coin toss. Both methods work well and might have more to do with what motor you currently have than any IDEAL combination.

So, Ford and Chevy folks, did that More or Less answer your questions?

the power output of the already stout 550 hp 383 by nearly 100 hp. Whether your Ford or Chevy has less motor with more boost or more motor with less boost, it’s tough to beat a supercharged small block. Of course the ultimate combo is always more motor and more boost! (Dyno Chart/Richard Holdener)

Comments