It’s not quite a Chicken Little moment where the sky is falling, but the disappearance of good Gen I small block Chevy engine blocks is a major concern. If you are one of the country’s largest small-block Chevy engine builders like Blueprint Engines, then you know that usable, standard bore block cores are becoming harder to find. The ideal solution would be to build your own. That’s an expensive investment, but that’s exactly what Blueprint Engines did.

But Blueprint sells crate engines, not individual parts. That’s what Summit Racing does. So The companies made a deal: BluePrint uses the new blocks as the foundation for their engines and Summit Racing sells bare blocks to engine builders under Street, Performance, Competition (SPC) name. Either way, you win.

Available in both 4.00- and 4.125-inch bore sizes with the choice of a one- or traditional two-piece rear main seal, The Summit Racing™ SPC Engine Blocks are capable of handling 700-plus horsepower. There are rumors that a block is already out there handling 1,500 horsepower with no signs of distress.

One of the advantages of being the last to attend this ‘block party’ is that you have the opportunity to remedy all the inherent flaws of all the previous versions. This story will detail all of the important specs you’ll need to evaluate these new SPC blocks along with several third-party measurements to establish the accuracy of the machine work. The message is that a strong casting is only half of the story. If the machine work is not accurate, the more discerning engine builder is forced to spend additional money–perhaps equal to the cost of the original block–to achieve the most power and reliability out of the engine.

Measure, Measure, Measure

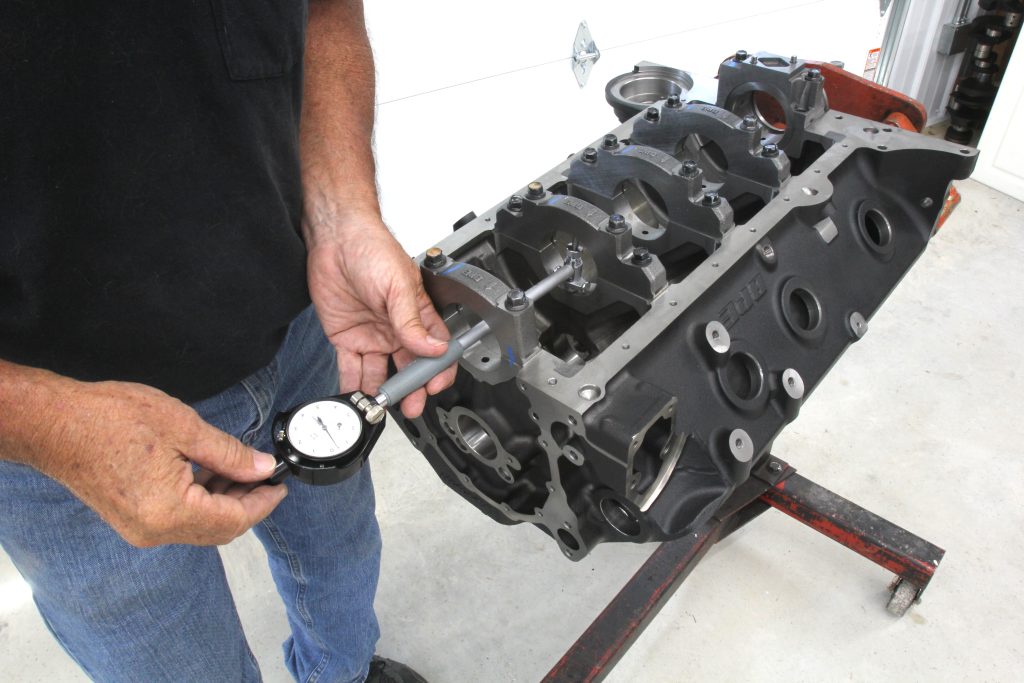

There are a few critical areas where proper machine work can be evaluated to determine the quality of the final product. This story was originally intended to farm out these block measurements to a professional race engine shop to carefully measure Summit Racing SPC block against GM’s own specs. But during the wait, Chris Straub of Straub Technologies in Piney Flats, Tennessee published his own independent evaluation of the block, so we chose to trust his measurements.

Straub set the stage by stating, “Out of all the aftermarket blocks we’ve have had on the machine, the Summit block was the closest to the GM (blue) print.” The machine he is referring to is a Rottler F69A. It can not only measure component locations with a wireless probe for automatic centering on items like cylinder and lifer bores, but it can perform the machine work as well. Rottler claims measurement accuracy of +/- 0.0002-inch.

Straub told us that the SPC block deck surfaces measured to within 0.002-inch on one side and 0.003-inch of true parallel on the opposite side. The cylinder bores were within 0.0015-inch for consistency within the GM-spec 4.400-inch bore spacing. Straub also reported that the main housing bores for the crankshaft were also right in the middle of the GM spec. This consistency is incredibly helpful when setting main bearing clearances.

One particular measurement point that we were interested in has to do with the position of the lifter bores relative to the camshaft. The camshaft centerline measured within 0.0015-inch of parallel with the main bearing bores. Straub also reported that each lifter bore was within 0.001-inch of true vertical relative to the camshaft center line and within 0.003-inch of horizontal. Between these two specs, the vertical is the far more critical since valve timing will suffer if the lifter bore is not “square” to the camshaft lobe.

This brings up an important monetary consideration. While this new casting is certainly more expensive than an older production block, consider the total cost of the substantial machining that must be invested in a used block to bring it into spec. Assuming the block is not cracked, it is not unusual to spend $1,000 or more to machine a block to achieve the proper specs.

This author recently spent over $2,800 in machine work to bring a late ’70s production block into spec. This included aligning the cam bearing bores and adding lifter bore bushings. The result was an older block within the specs of the Summit Racing SPC blocks. It would have been far less expensive to invest in the new block.

Modifications and Improvements

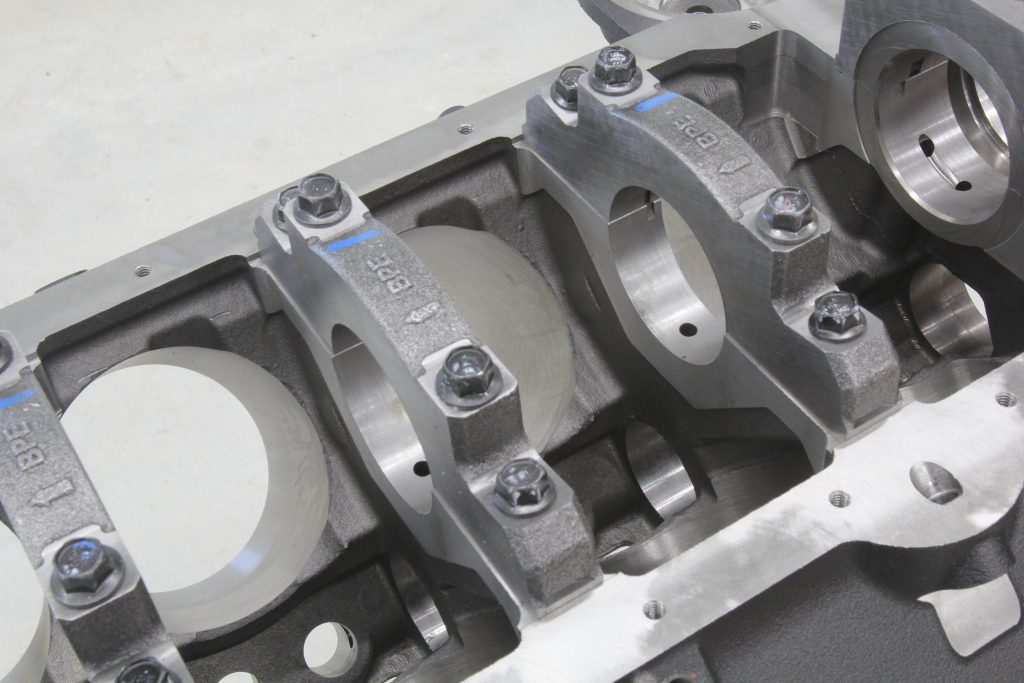

Now that we’ve established the precision machine work present in these new castings, let’s talk about block modifications and improvements. The first major change to the SPC block is the addition of priority main oiling. This is where the crankshaft receives oil directly from the oil filter as opposed to the OE path that pushes oil to the lifter bores first and then to the crankshaft.

The block deck height is slightly shorter at 9.00-inches as opposed to the OE spec of 9.025-inch because most aftermarket pistons are configured for the shorter deck height. The deck is also strengthened with a minimum 0.600-inch thickness.

One of the advantages of the tighter machining clearances is that when pre-assembling the engine to check the piston-to-deck height spec, older production blocks can vary by as much as 0.015-inch. The SPC block will likely measure closer to 0.002- to 0.003-inch in variation between all eight pistons. That eliminates the necessity of shaving the block to optimize this spec.

For the record, the SPC blocks require finish honing to establish the proper piston-to-wall clearance. Cam bearings will need to be installed before the block is ready for assembly.

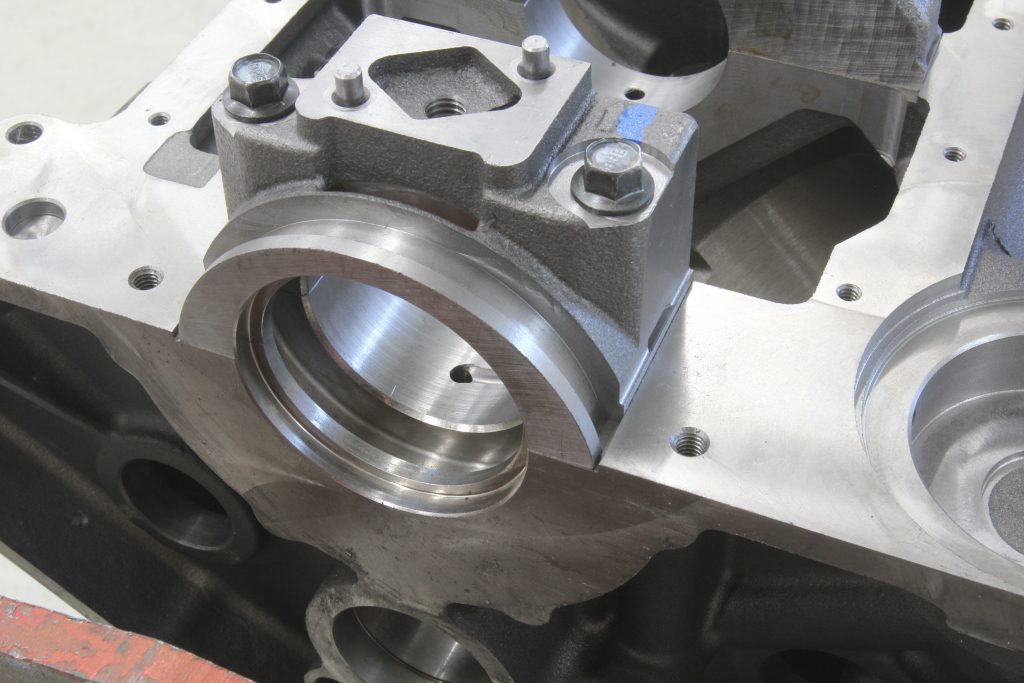

Both the 4.00- and 4.125-inch bore blocks can be safely bored to a maximum size of 4.185-inch while maintaining a minimum thrust side wall thickness of 0.220-inch. For the 4.125-inch bore castings, buyers can choose the larger 400 style main journal housing size or the smaller 350 style mains. If a long-stroke combination is under consideration, be aware that 4.00-inch stroke cranks are generally ground using the larger 400 style mains for additional torsional rigidity and strength.

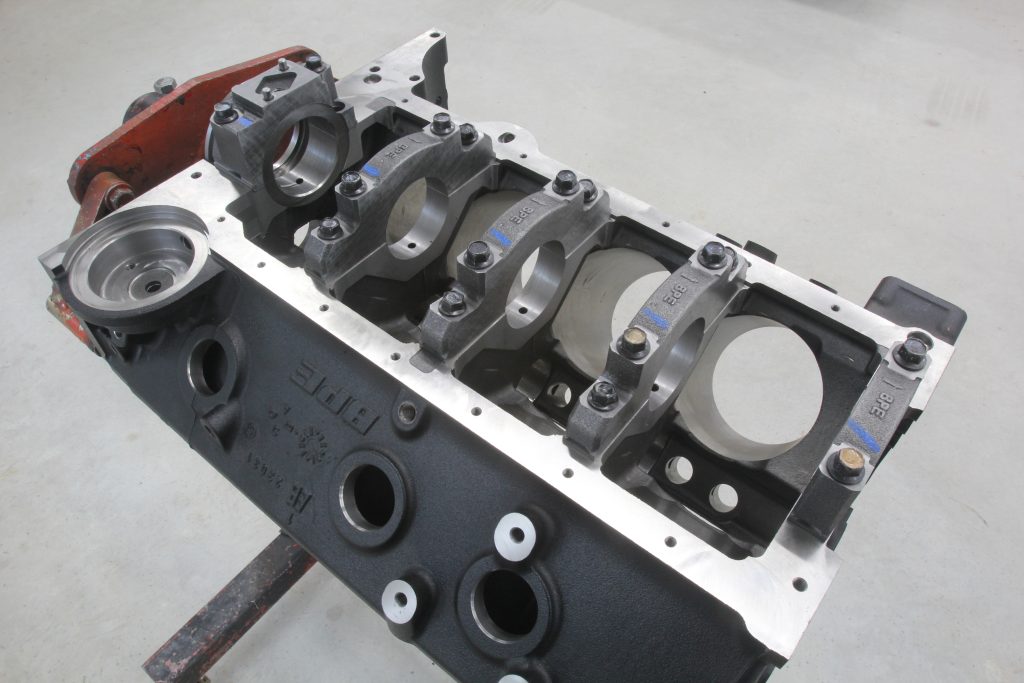

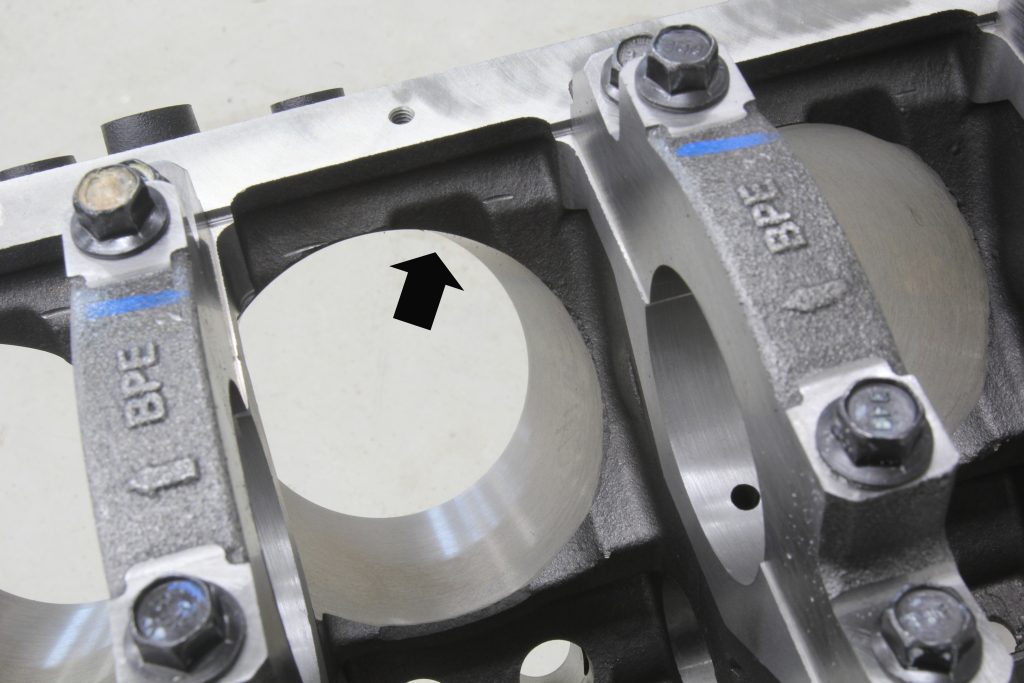

Summit Racing SPC Blocks all come with four-bolt mains with the outer splayed bolt holes in the smaller 3/8-inch configuration. Summit Racing’s Brian Nutter told us this is because the outer bolts’ main job is to minimize lateral cap walk and play only a very small role in vertical cap loading.

While we’re in the crankcase area, the pan rail section has been designed with a factory relief that Summit Racing says will accommodate most, if not all, 3.750-inch stroke steel rod combinations. If a longer stroke is under consideration, this area can be further relieved because the water jackets normally found in this area have been removed, making this area solid to aid in block strength.

All Summit SPC blocks are cast with siamesed cylinder liners. This means that the outer portions of the common walls between cylinders are connected. This reduces coolant contact, but this is offset by the additional strength offered with this construction technique.

Here are some smaller yet still important pieces of this small-block puzzle:

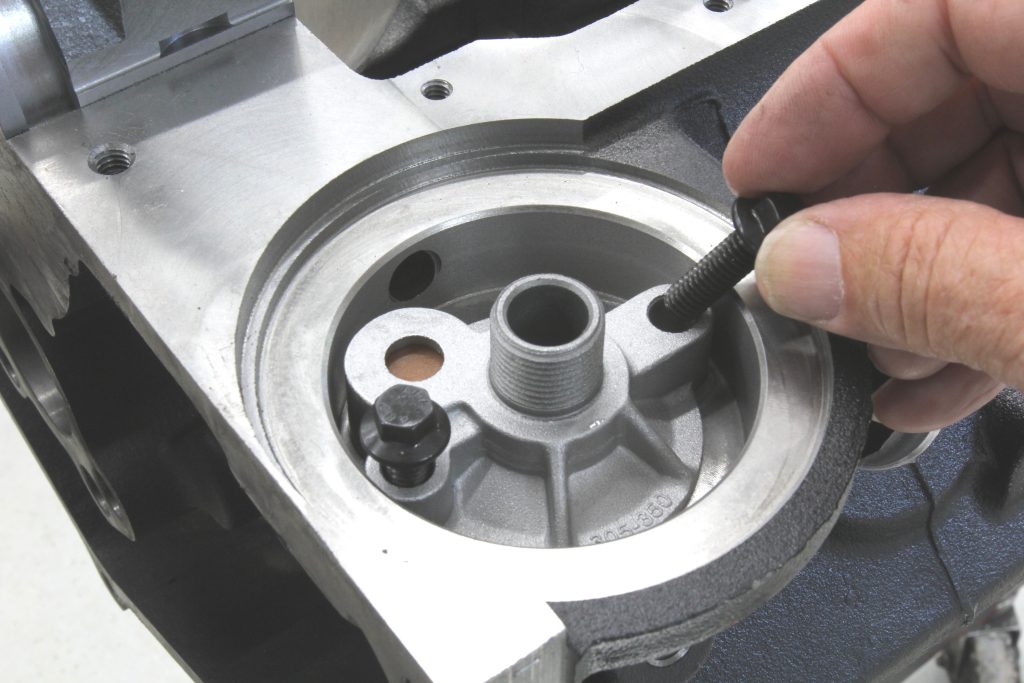

• Machined to accept a mechanical fuel pump in the OE location

• Machined to accept both the small diameter (straight across) flywheel/flexplate starter motor nose and the offset, large diameter nosepiece

• Accepts a standard small-block Chevy spin-on oil filter adapter

• Two different mechanical clutch linkage ball stud locations

These SPC blocks require a larger number of production style pipe plugs for both oil galleys and outside block drain fittings. We counted nine that will be needed to plug all the tapped holes in this block. You will also need two 1/8-inch NPT plugs for the drilled and tapped boss at the front of the lifter valley that was required to drill lubrication galleys for the priority main oiling system.

Finally, all head bolt holes are blind holes, which means they do not extend into the water jackets. This is a critical point because the length of the head bolt must be accurate to prevent damage to the block. A too-long head bolt can easily bottom out and crack the block. We’ve seen this happen to a brand new aftermarket block with blind head bolt holes. The ugly result was a serious crack in the block deck that required extensive machine work to add two cylinder sleeves to repair the damage caused by a non-attentive engine builder. So don’t be that guy.

Combine modern, CNC-machining accuracy with all the benefits of economy of scale and a high production rate and you’ve got one of the best deals on the planet for building a small-block Chevy. Let’s take a closer look.

Summit Racing SPC Engine Block Specifications

Material: Iron alloy Class 35

Weight: 181-194 pounds based on bore size

Deck Height: 9.00 inches

Deck Thickness: 0.60-inch

Bore Spacing: 4.400 inches

Maximum Bore Size: 4.185 inches

Minimum Cylinder Wall Thickness with 4.125 Inch Bore: 0.2200-inch

Main Journal Size: 2.4485 inch (350), 2.659 inch (400)

Rear Main Seal Style: Choice of 1-piece or 2-piece

Main Cap Material: Nodular iron

Main Cap Bolts: 7/16-inch Inner, 3/8-inch outer

Stroke Clearance: Up to 3.750-inch

Lubrication System: Priority main

Cam Location: Stock

Cam Bearing Bore Size: 2.000-inch +/- 0.001

Lifter Bore Size: 8.437-inch +/- 0.0003

Machined for OEM Hydraulic Roller Lifters: Yes

Oil Pan Rails: Solid (no water jackets)

Starter Motor Mounting: Drilled and tapped for both straight and offset

Mechanical Fuel Pump Provision: Yes

Dipstick Location: Passenger side

Water Jackets: Larger than OE

Block Coating: Black powdercoat

Parts to Complete Block Assembly

Durabond Cam Bearings: DUR-GMP-8

Summit Racing Brass Freeze Plug Kit, 2 required: SUM-G1581

Pioneer 1/4-Inch Pipe Plugs, set of 25: PIO-PP-584-25

Summit Racing Oil Filter Adapter: SES-3-60-08-900

Fel-Pro 2-Piece Rear Main Seal, 350 main: FEL-BS40013

Fel-Pro 2-Piece Rear Main Seal, 400 main: FEL-2909

Summit Racing Cam Limiter Plate: SUM-150-130

Chevrolet Performance Fuel Pump Pushrod, 0.500-inch: NAL-3704817

Summit Racing Chrome Fuel Pump Block-Off Plate: SUM-401030

Summit Racing Oil Pressure Adapter, 1/8-inch NPT to -4 AN: SUM-220446

ARP Oil Pump Stud (high-volume oil pump): ARP-230-7003

ARP Oil Pump Driveshaft: ARP-134-7901

Pioneer Front Timing Cover Dowel Pins: PIO-839059

Chevrolet Performance Bellhousing Dowel Pins, 2 required: NAL-1453658

If only it was possible to buy these with finished, nominal-sized cylinder bores. Not having that option leaves a lot of people out in the cold and forced to choose between buying an assembled short block, or nothing. Machine shops aren’t exactly thick on the ground out here like they used to be 30 years ago.

i understood it to be that a hone job was all that is needed in the cylinders. is that not correct?

Hey guys, proper cleaning and final hone will be required for a couple reasons. Piston manufacturers don’t always know the environments their pistons will be used in. Boost or nitrous levels (along with different ring surface-finish requirements) are examples where a seasoned machinist (with precision dial bore gauges and profilometers) can help ensure a customer’s success.

I know the reasons for honing to a specific application & ring type, that was never the issue. Large parts of this country simply no longer *have* a local machine shop anywhere within 100 miles, and farther out than that and you’re into a different state and talking about a trip that includes things like an overnight stay…

‘just take it to the machine shop!’ – right. Wish I lived wherever you do, cause it don’t work like that here.

On the product pages they say bores are .005″ undersize (3.995″/4.120″).

One of the things I saw in the catalog was a 400 main size with 1 piece rear main seal. I didn’t think this was a possibility and I didn’t think crankshafts were made to fit that. It seems like a typo to me, but maybe I don’t understand how you can have both of those together, which the factory definitely never did.

Hey Robert, the SPC blocks with a 1-piece RMS are available with 400-style mains with a 4.125″ bore. Check ’em out here.

And that link leads to the only actual choice for 400 mains: a _2_-piece RMS!

Robert

There is a Summit block with a 4.120-inch bore, 350 style mains and a 9.00 -inch deck height with a 1-piece rear main seal – the PN is SUM-150204.