My problem started with this new engine after the required break-in procedure. The motor initially sounded a little loud in the valve train and continued to get louder to the point where it sounded like a sewing machine without oil. After tearing it back down to replace the lifters (I was thinking lifters were crap), I found wear on the valve retainer caps and matching on the rocker arms.

What needs to be replaced to correct this problem? I am thinking a narrow rocker arm will fix the problem but then do I need to replace the retainers that are worn?

Engine Description:

- Pistons are flat-top aftermarket

- Camshaft is a Howards HRCCL112571-10

- 0.455 / 0.465, Duration @ .050: 215 / 225, Centerline: 106

- Lifters are Howards

- Heads are Flowtek 105-505FT (New, they came with springs and valves installed)

- Stock length pushrods

- Rockers are Summit Racing SUM-G6935-16

- Intake is a RPM Air Gap

- Holley Sniper for Fuel Delivery

Thanks

B.R.

***

Your problem stems from an unfortunate combination of parts—but the good news is that the solution is easy.

Here’s the background information. Sometime in the mid 1980s, Chevy changed from guiding the pushrods with small holes in the head to using what they call guided or self-aligning rocker arms. These were stamped rockers with small bumps pressed into the stamping on the rocker tip that centered the rocker arm over the valve tip. Prior to that, small holes in the head or pushrod guide plates kept the rocker arm centered over the valve tip.

Where this gets messy is that guided rocker arms require a taller valve stem tip above the retainer. This taller valve tip creates room for the guides on the rocker arm. When the aftermarket started to build roller rocker arms, they also built guided roller rocker arms for these later engines. That’s the style of rocker arm that you have.

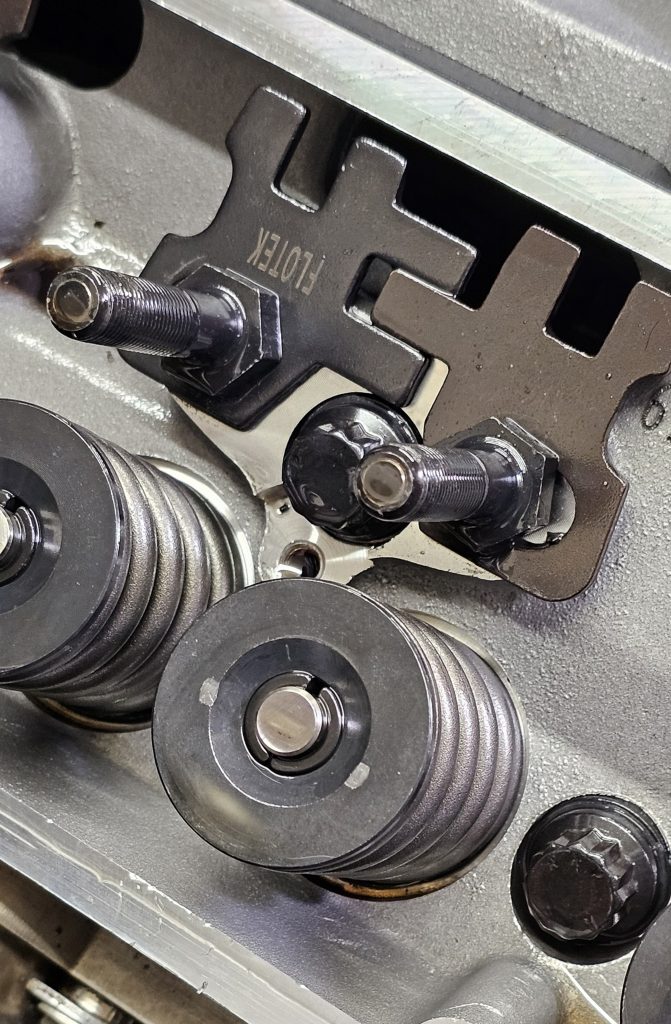

The problem is that the valve tips on your cylinder heads are designed for use with standard or older style rocker arms using guide plates. The issue is that you have guided rockers on heads designed for the original style roller rocker arms.

The alignment guides on the rockers are hitting the retainer because the valve stem tips are not tall enough to offer room between the guides and the retainer. The easiest solution is the replace those guided rockers with a set of standard roller rockers. At the bottom of this article, we’ve included a part number for the proper rockers assuming you have 3/8 inch rocker studs. We’ve also included a PN for rockers (standard, non-guided) for 7/16 inch studs.

You are frankly very lucky that the guides of the rocker arms did not unload the locks on the retainers. Had the guides unloaded the retainers, the locks would have fallen out and this would have dropped a valve.

That probably would have killed a piston or two and you would have a much bigger problem—so you dodged a bullet!

The other issue with guided rockers is to never use them with pushrod guide plates since this will put the rocker into a bind across the top of the valve tip. If you look at the photo carefully, some of the guide plates have pushed the rocker to one side. That also causes extreme wear problems with the binding that occurs. This will all be solved by running the correct rocker arms. .

Those adjustable guide plates are intended to be used to center the rocker arms over the valves with the correct, non-guided rockers. Once the rockers are centered, it is sometimes difficult to torque the rocker studs while keeping the guide plates from turning and creating a misalignment. This is why some builders set them and then tack weld them together to maintain the orientation.

There is another solution to your problem but that involves disassembling the heads and replacing all the valves with longer stem tips to allow you to use the guided rockers. If you were to do this—it would also mean eliminating the guide plates.

But from a cost and effort standpoint, it’s much easier to just to replace the rocker arms.

Oil & Other Considerations

You mentioned that this engine has flat tappet hydraulic lifters. We will assume that the break-in procedure was successful. We would recommend changing the oil and filter immediately before you fire the engine with the new rockers. This will ensure you’ve removed as much metal from the engine as possible—but it might be worthwhile to also perform a used oil analysis test just to make sure the engine is in good shape.

It’s also important to use the correct high-ZDDP engine oil to protect your flat tappet lifters. There are several high-zinc and phosphorous oils to choose from that are available from Summit Racing. We’ve listed these different engine oils in the parts list but Driven, Lucas, Summit, Valvoline, and others all make a quality product that will protect your lifters.

With a change to the correct rocker arms and replacing the damaged valve spring retainers along with an oil and filter change your engine should be ready for a long life of spirited driving!

Solving a Noisy Valvetrain Parts List

- Summit Racing 1.5:1 ratio roller rocker, 3/8” stud – SUM-G6910B

- Summit Racing 1.5:1 ratio roller rocker, 7/16” stud – SUM-G6911B

- Summit Racing high-zinc hot rod oil, 10w30 – SUM-1-10W30

- Driven GP-1 10w30, semi-synthetic – JGR-19306

- Driven conventional 10w30 – JGR-02006

- Lucas Hot Rod classic 10w30, 5 quarts – LUC-10679-1

- Valvoline VR-1 synthetic race, 10w30, 6 quarts – VLV-679083-6

Comments