Boost has long been the big equalizer. Add boost to just about any engine, and all of a sudden you have transformed your otherwise mundane motor into some kind of super hero.

This seems to be especially true of LS engines.

We all know that boosted LS motors make huge power, but when you go looking for boosted performance, should you be looking at things like wilder cam timing and intake upgrades?

…Or should you just run more boost?

For our test, we decided to illustrate what happens when you make bolt-on modifications to your 5.3L and what happens when you combine them with additional boost. As we know, boost is just a multiplier of the original NA power output, so the more NA power you make, the more boosted power you can make at any given boost level.

While our 5.3L from Strictly Performance was not what you would call a junkyard motor, all the mods performed to the 5.3L can just as easily be performed on a junkyard 4.8L, 5.3L, or 6.0L truck motor. Just add the necessary ring gap to your junkyard motor an away you go, but let’s take a look at what happened when we performed some mods on the 5.3L test motor equipped with a Vortech supercharger.

The 5.3L Motor Baseline Configuration & Test

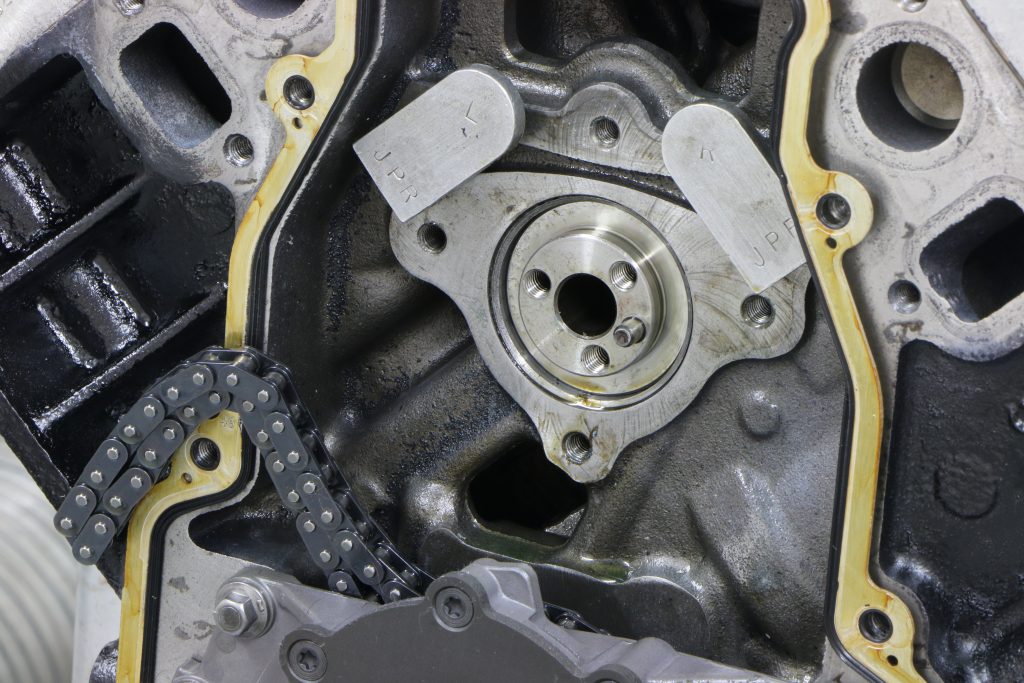

In essence, the Strictly Performance 5.3L could be thought of as an augmented stock 5.3L short block.

The stock block was equipped with a stock crank, Gen. IV rods, and cast pistons. The cast pistons were hard anodized to further improve strength, and the ring gaps were opened up for boosted use.

The lone performance modification to the 5.3L was additional head flow in the form of ported 706 heads from Katech. The 706/862 heads featured full CNC porting but retained the stock valve sizes. Think of this as a low-buck, but effective version of race porting.

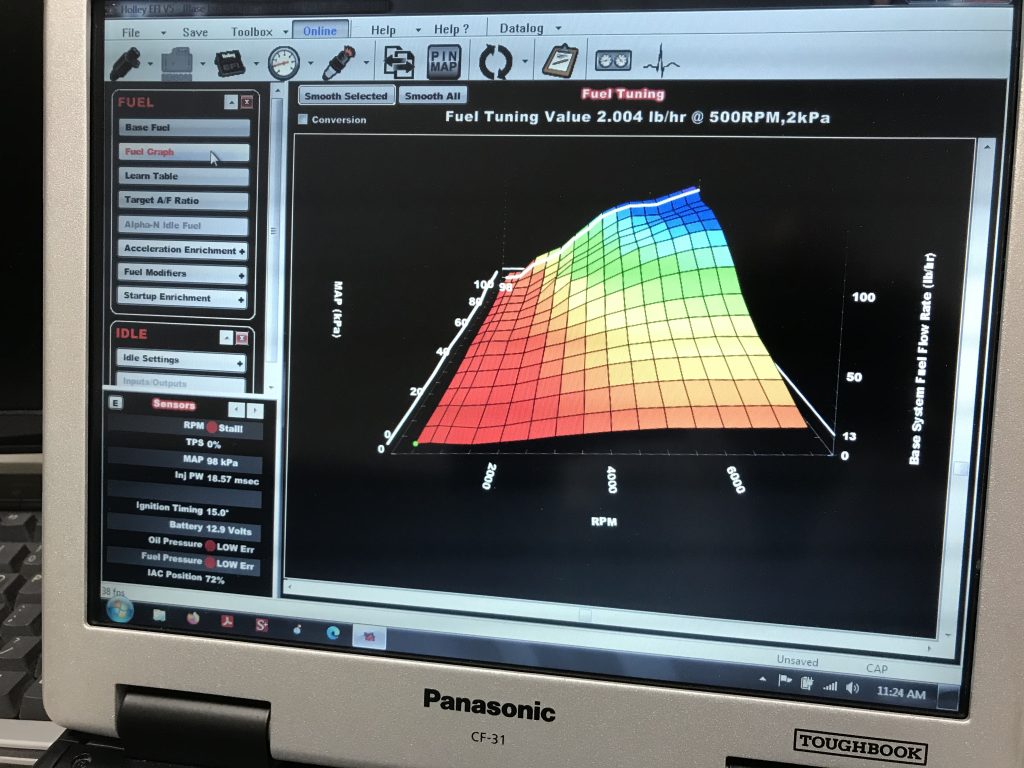

The remainder of the combo include a truck intake and throttle body, a set of 80 pound injectors and long tube headers. The 5.3L was first equipped with an LS9 cam and the heads were treated to a BTR dual valve spring upgrade in anticipation of future cams.

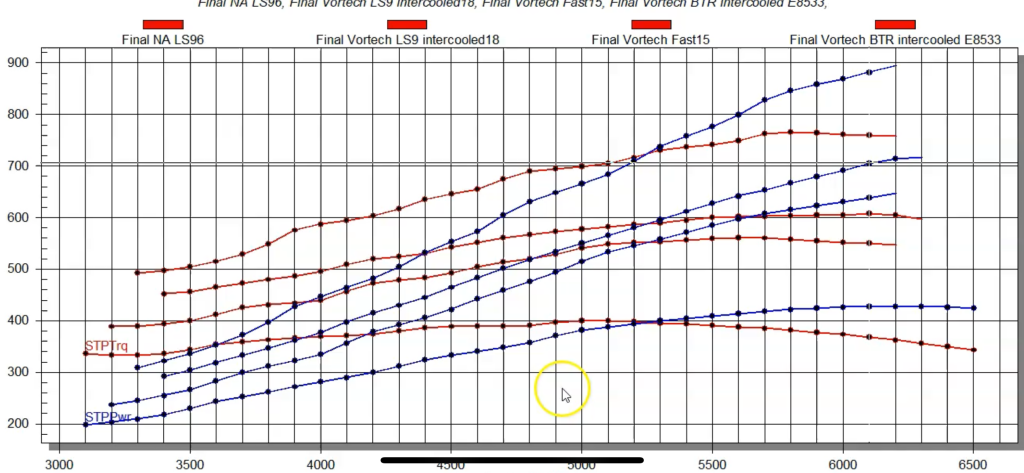

Run in this manner with a Holley HP management system, the 5.3L produced peak numbers of 428 hp and 400 lb.-ft. of torque.

The factory LS9 cam has long been a favorite of LS enthusiasts, mostly because it is the most powerful factory cam offered by GM (a title shared with the LS7). The LS9 cams are also readily available, with plenty of used ones from guys who have performed cam swaps on their factory supercharged LS9 motors. The downside of the LS9 cam (designed for a positive displacement blower application) is the general lack of low-speed torque.

But fear not—we had a cure.

Adding a Vortech Supercharger & Other Mods

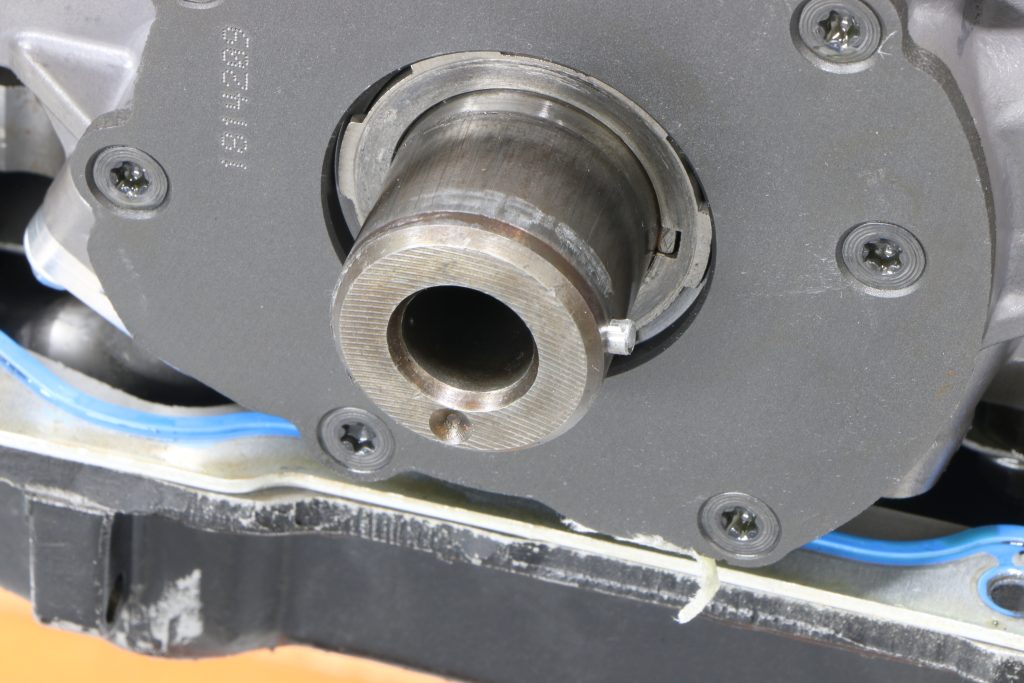

After running the 5.3L in anger, we installed the Vortech SI-trim supercharger kit, along with a (not stock) air-to-water intercooler from ProCharger. The motor was run on a combination of 91 and 100 octane to allow for proper timing values to maximize power. The Si-trim Vortech was equipped with a 3.6 inch blower pulley. When combined with the stock truck damper (pinned in place), this produced a peak boost reading of 8.4 psi.

In typical centrifugal supercharger fashion, the boost supplied by the Vortech rose from 2.5 psi before hitting the peak of 8.4 psi, where the supercharged 5.3L produced 647 hp and 561 lb..-ft. of torque.

Wanting even more power, we replaced the LS9 stick with a healthy camshaft from Brian Tooley Racing that upped the spec ante to include a 0.613/0.596 lift split, a 227/244 degree duration split and 115 degree LSA. To further maximize power, we replaced the 91/100 mix with E85 purchased from a local gas station (we never even tested the true mix, which can vary greatly).

Run with E85, the BTR cam and same pulley combo, the peak numbers jumped to 716 hp and 607 lb.-ft. of torque.

The combination of cam timing and E85 improved the power output of the 5.3L through the entire rev range, always a good sign, but we were still had 1 more round of mods in store for the Vortech 5.3L.

More Upgrades to the 5.3L LS Test Engine

The final list of modifications (many of these were tested individually-but provided here in mass due to space constraints) included a new intake, larger cam and supercharger. The factory truck intake and throttle body were replaced by a FAST LSXR intake manifold and matching FAST 102mm throttle body.

The intake upgrade was teamed with wilder cam timing in the form of a Stage 4 camshaft from Summit Racing. The Stage 4 cam featured a 0.625/0.605 lift split, a 234/247 degree duration split and 113 degree LSA.

The cam and intake upgrade were given both additional flow potential and boost in the form of a T-trim supercharger from Vortech. The T-trim was spun up with a 10 rib ATI Super Damper and 8 rib, 3.33 inch blower pulley. The FAST intake upgrade also necessitated an injector swap. The combination of the ATI damper, 3.33 inch pulley and T-trim blower resulted in a peak boost of 13.8 psi supplied to the new 5.3L combination.

It should be noted that the NA version of this 5.3L touched 500 hp, but with the boost supplied by the Vortech, the combo belted out 895 hp and 766 lb.-ft. of torque.

Given the power gains vs. rpm, we figure the near 900 horsepower output was a long way from being maxed out at just 6,200 rpm.

Once again, the only thing better than bolt-ons OR boost…is bolt-ons AND boost!

Thanks for all you do to help others improve their builds.

Very interesting reading.