Ford’s newest V8 has made a splash as of late both with the new truck market and on the aftermarket hot rod scene. While small-displacement, overhead cam engines have been the norm from the Blue Oval, the Ford 7X 7.3L “Godzilla” breaks that trend by becoming the first pushrod, cam-in-block V8 since the 302 and the 351W disappeared at the end of 1995.

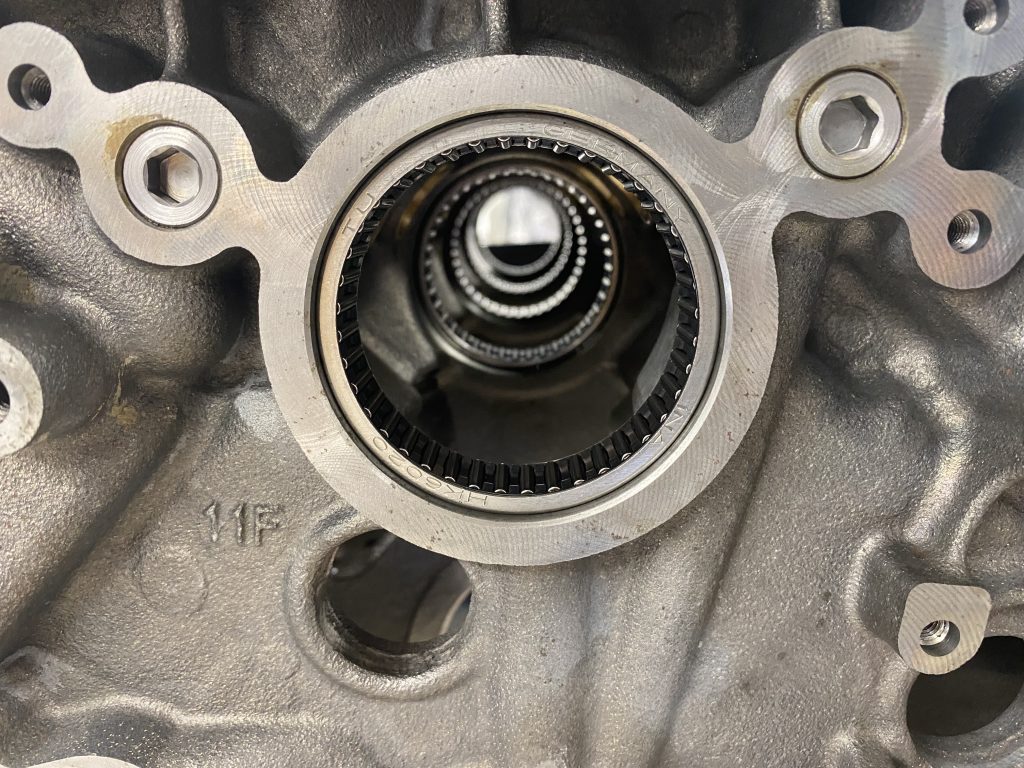

While not classified as a performance engine the 7.3L (445 cubic inch) engine has the DNA that great engines are made of. It has sizeable cubic inch, 6-bolt crank retention, 60mm cam journals, big valves with high-flow ports, and a steel crankshaft.

It’s been a great option for engine swap, as stock engines have produced upwards of 600-plus horsepower with free-flow exhaust and not much more. Better yet, the aftermarket has jumped in with both feet to offer just about everything you need whether you’re after 600 ponies or 1,600.

The brainchild of former director of Ford Performance, Brian Wolfe. (Note: Wolfe is now retired from Ford, but continues to drag race his Ford Mustang), the Godzilla was developed as a Super Duty truck engine. It’s offered in the F-250, F-350, F-450, and in various commercial and fleet applications including motor homes and delivery trucks.

To learn more we spoke to Blaine Ramey, former supervisor of large gas and diesel engine performance development at Ford Motor Company. Ramey is also a hardcore drag racer, who’s teamed with Paul Svinicki on a Godzilla-powered Cobra Jet Mustang that runs in NMRA and NMCA action.

“When the project kicked off Brian [Wolfe] was the director of global engine engineering. We decided to go with a brand-new design, one that made the most sense,” said Ramey. “We essentially had a clean sheet of paper and this design offered the customer what we’re looking for in that segment. Basically, it fits the heavy-duty truck market and we wanted to have a common engine that would go across the board. This will be in dump trucks, motor homes, and pick-up trucks. We needed a relatively compact package with low cost and high reliability. It made sense to do a pushrod V8 for cost to the customer and maintenance.

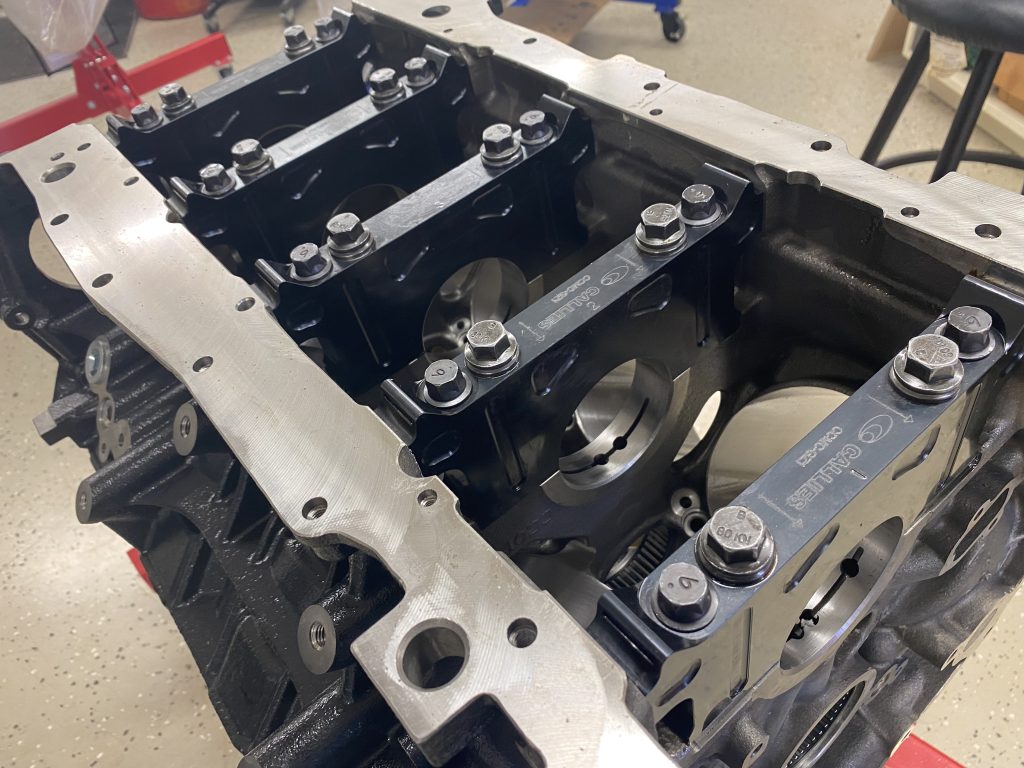

“This engine uses everything that Ford has learned,” he added. “The same guy who did the 5.0L and the 5.2L Shelby [GT350] intake port developed this engine. It’s brand new with no compromise. It is designed to be very rugged. It’s a cast iron, four-bolt main block with cross bolts, and the pistons and rings are an evolution of the EcoBoost design. There are fewer parts and it’s built in Windsor [Ontario]. In contrast, the DOHC V8 engines use 32 valves, this has 16, plus one cam versus four.”

Ramey also told us the block is fully skirted, which adds rigidity. Bore and stroke comes in a 4.22 x 3.976 inches respectively to produce 445 cubic inches of displacement. “We wanted to have a relatively good performance potential so it has large bores. This is good for cylinder head flow and creates slower piston speed during cruise modes for better efficiency,” said Ramey.

Fordnatics have responded, too, as we’ve seen a multitude of Godzilla swaps, from Foxbody and classic Mustangs to old Broncos and trucks. Wolfe himself has been campaigning a n Ultrastreet/Renegade Foxbody Coupe with a ProChargered Godzilla. It’s produced upwards of 1,650 horsepower and has run 7s in the quarter mile. Ramey and Svinicki have dipped in the 9s with a relatively stock engine and 8s with nitrous.

“We also designed the engine to be serviced and rebuilt in the future. So, for these reasons the iron block made the most sense. Another benefit is improved thermal efficiency.” Ramey stated the engine was designed with longevity in mind.

The block can be bored and honed at least 0.010 inch according to Ramey, but we suspect there’s plenty of meat to go 0.030 inch over (or larger), which would give you 457 cubes. Some insiders say a bore and stroke upgrade could net over 500 cubic inches! In fact, Wolfe is currently working on a 490 inch all-motor combination that he estimates will produce 900-plus hp.

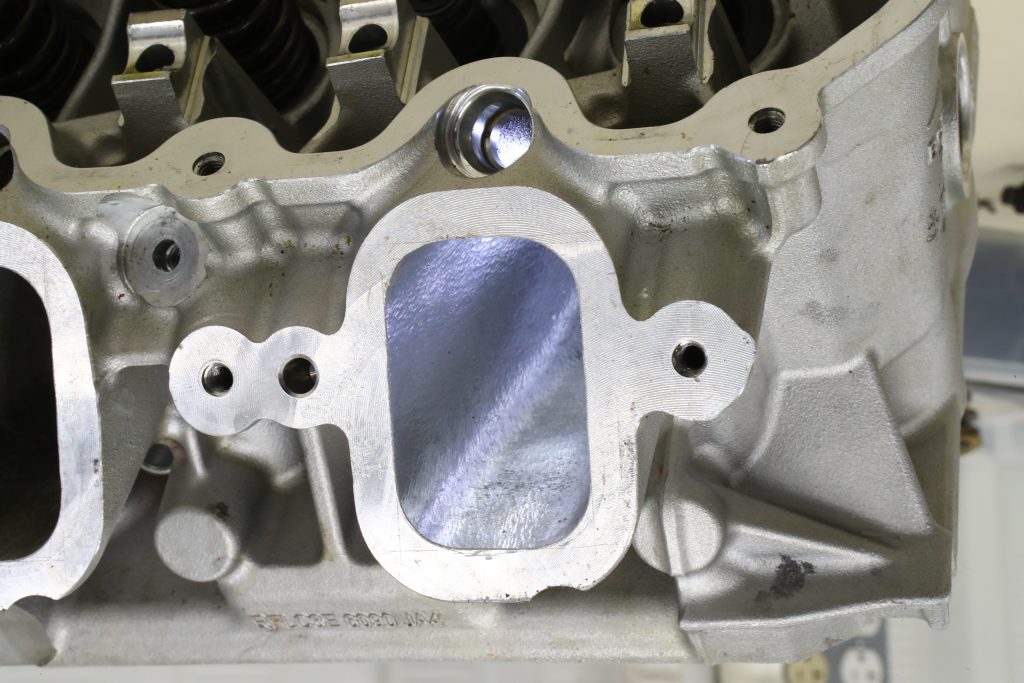

Since its introduction, Ford has improved the intake design and there are plenty of aftermarket Godzilla intake manifolds on the market today.

All intakes use a flat mating surface to the heads and O-ring gaskets per port. This improves sealing and speeds assembly, and you can do an intake swap in minutes! It also has a dry valley so there’s less chance of an oil leak.

The heads are aluminum with tall ports that were developed for good flow and charge motion.

“We have a wedge combustion chamber, and the spark plug location is optimized at the center of the dish for the ability to have higher compression ratio. That equals better efficiency and performance. We also used piston-cooling jets that flow oil to the back side of the piston. This cools the pistons under high load to prevent detonation. And we control oil pressure with the variable-displacement oil pump. We can control the oil pressure in the engine to give a target pressure with the variable-displacement oil pump. At idle we don’t need much pressure, at higher speed or load we can increase pressure to protect the engine.”

Comments