Why do people choose the larger 6.0L over the smaller 4.8L and 5.3L when it comes to time to make power?

Why is the larger motor more expensive and harder to find in wrecking yards? Basically, why is the 6.0L better than its smaller siblings?

The answer is power!

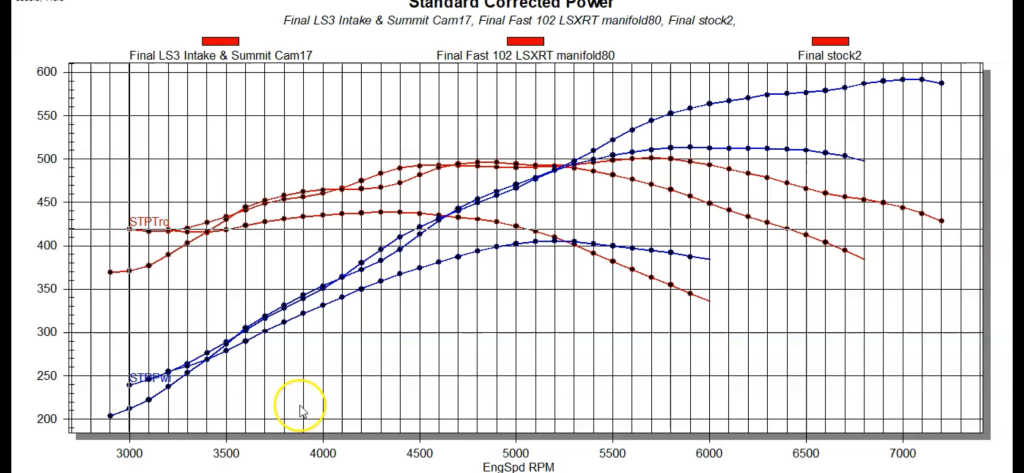

Bigger motors flat out make more power, and not just more peak power, but more average power. Peak numbers are all well and good, but what really makes a combination successful is additional power through the entire rev range. Compared to the smaller 4.8L and 5.3L motors, the 6.0L not only makes more peak horsepower and torque, it also makes more power from off idle all the way to redline.

Having more average power translates directly to quicker acceleration. It can also translate into improved towing power or heck, a good, old-fashion smoke show! Whatever your needs, a bigger motor can make it happen sooner.

But just because you have the bigger 6.0L, doesn’t mean you can’t make it better. After all, the only thing better than a stock 6.0L is a modified one, so let’s take a look at three different NA 6.0L builds, ranging from mild to wild, including a stock LQ4.

400 Horsepower 6.0L LQ4

To reach the 400 (flywheel) hp mark, we need to first understand the difference between rated and tested power output.

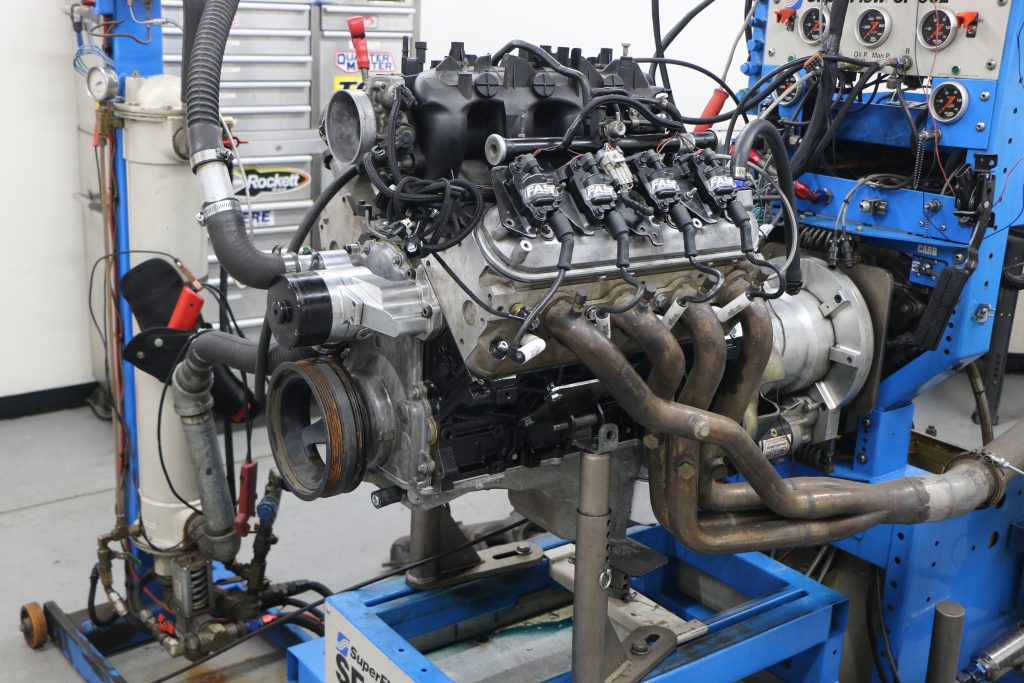

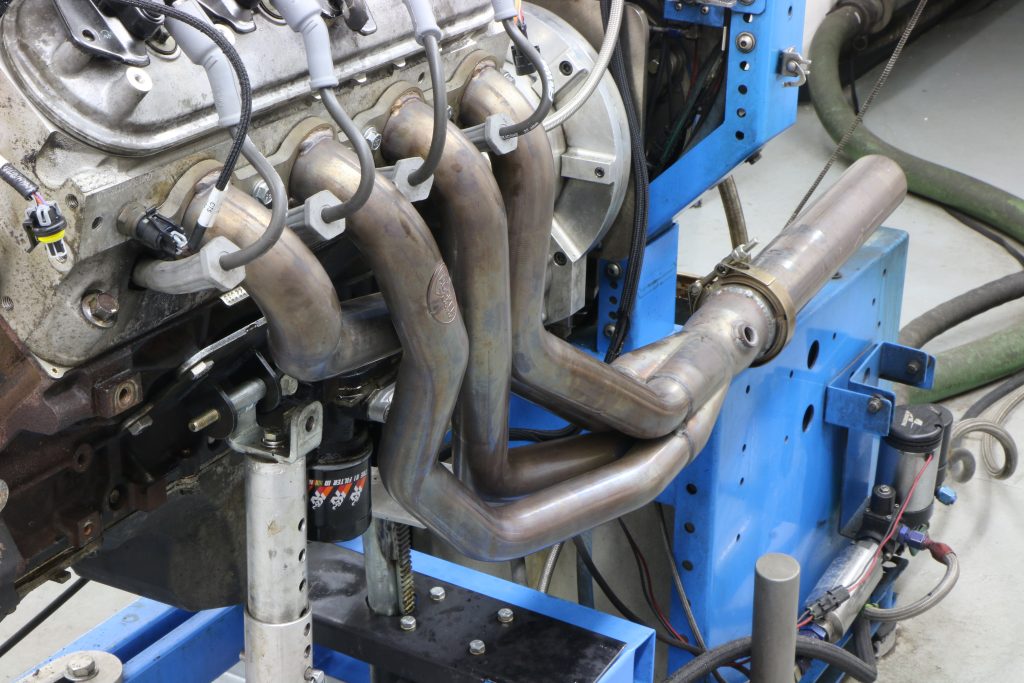

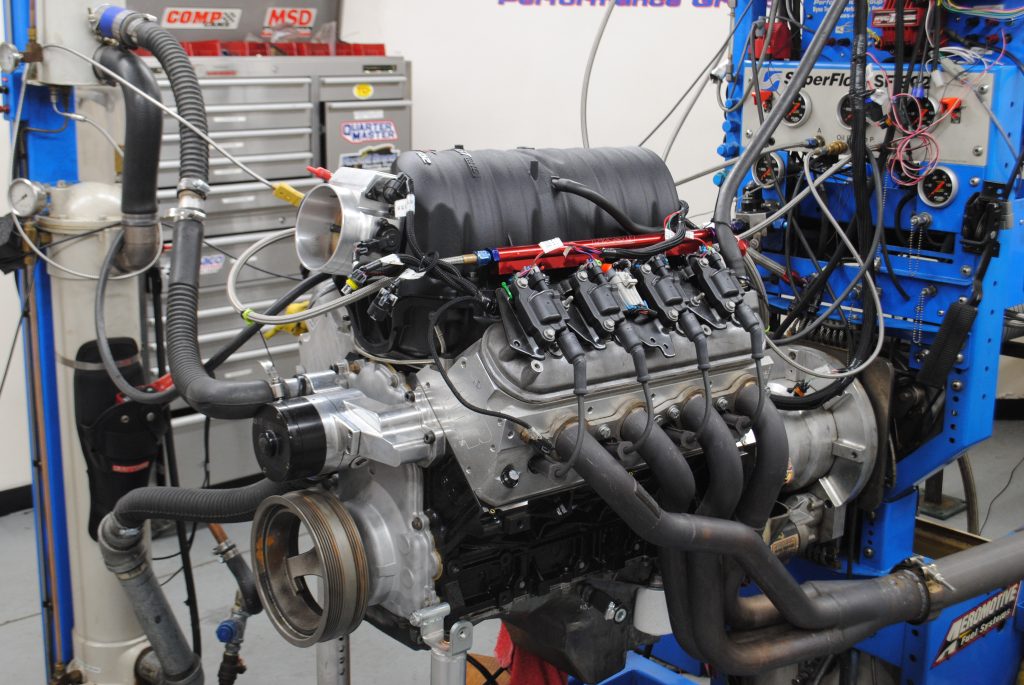

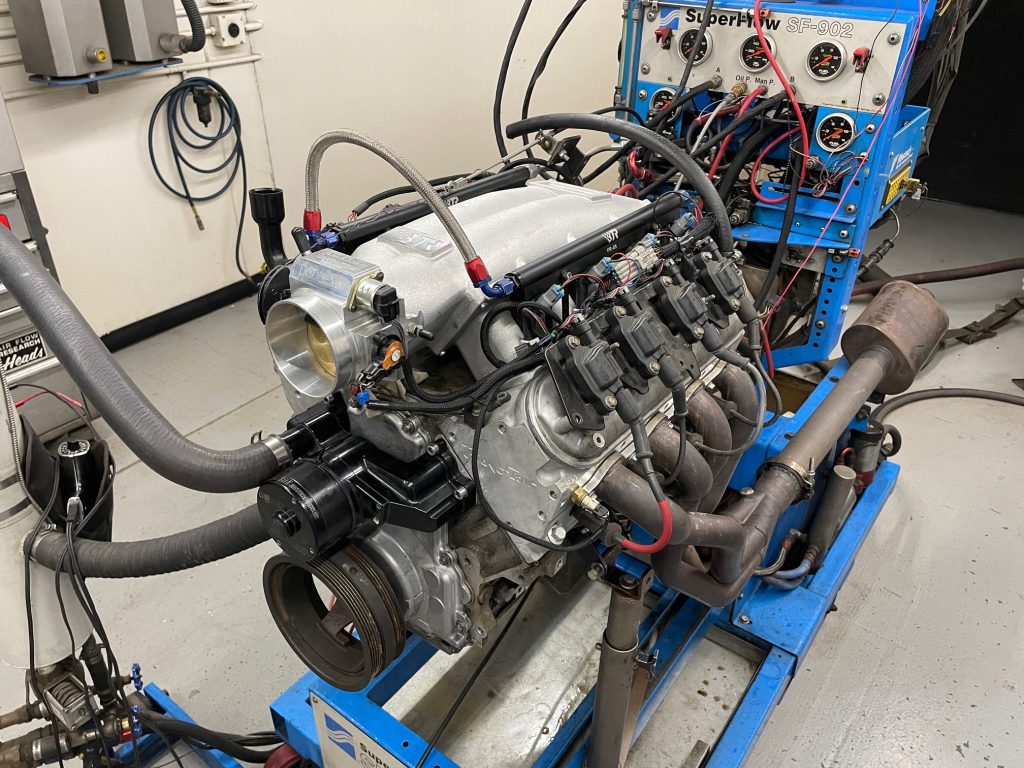

The GM factory (flywheel) rating is run in stock trim, at normal operating temperature, with full exhaust and air intake, with full accessories and the factory (non-optimized) tune. On the engine dyno, we tested the “stock” rebuilt 6.0L LQ4 in a different configuration, as the LS was run with no accessories or air intake, with long-tub headers and three inch exhaust and with an optimized tune (and colder).

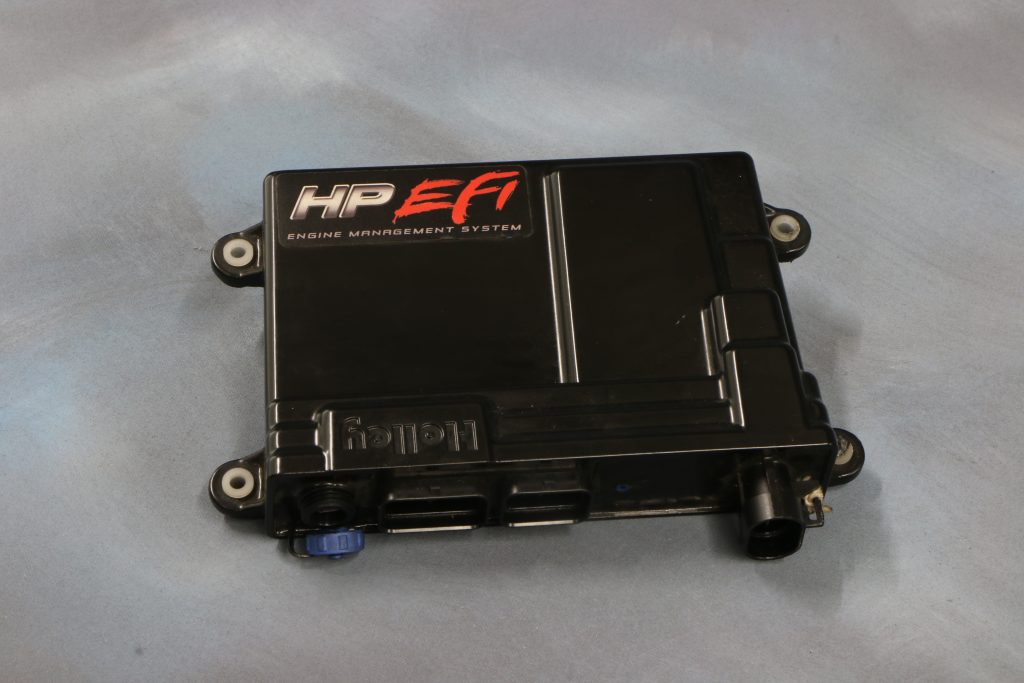

These changes released additional power from the 6.0L, which is why our “stock” LQ4 made more power than the rated output (which varies with year and application). The junkyard 6.0L was given an overhaul, with a ball hone, new rings and bearings, and a fresh valve job on the 317 heads. The LQ4 was equipped with the later LQ4/LQ9 cam (early models shared the smaller LM7 cam), the stock early truck intake and throttle body and run with a Holley HP management system controlling 80 pound injectors (used for later testing).

Run in this manner, the LQ4 produced 402 hp at 5,200 rpm and 438 lb.-ft. of torque at 4,300 rpm.

The 400 hp 6.0L truck motor did exactly what we expected, making peak power low in the rpm range to enhance torque production, but how do we now get even more power out of a 6.0L?

500 Horsepower 6.0L LY6

Given that the stock LQ4 made right at 400 hp and 438 lb.-ft., what does it take to get a 6.0L to reach the 500-hp mark?

The answer, as always with LS motors, is a cam swap.

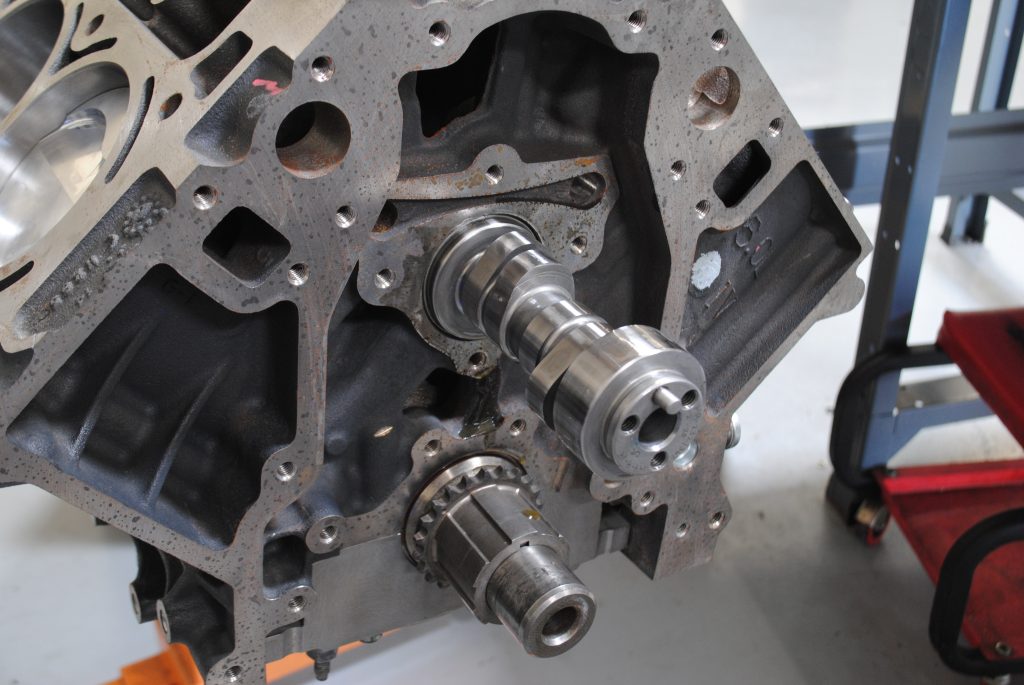

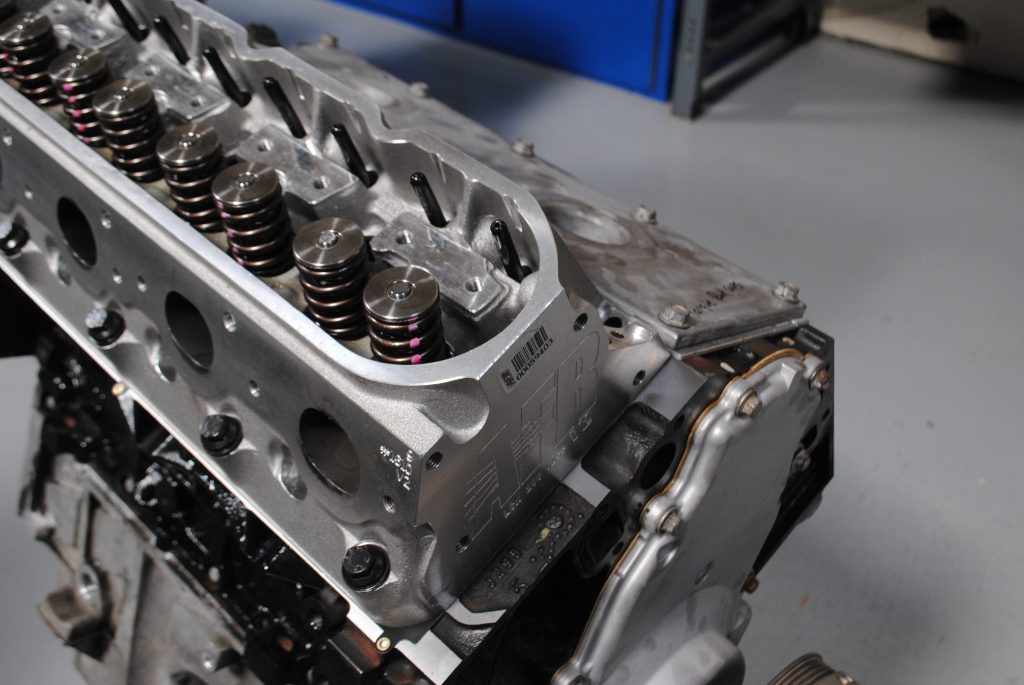

In truth, this 6.0L combo also benefitted from additional head flow, as we started this build up with an LY6 6.0L instead of an LQ4/LQ9. The LY6 started out life with rec-port (LS3) heads and variable valve timing (VVT) and an equally good rec-port intake manifold. Exceeding 500 hp only required replacing the factory VVT cam with (in this case) and Trick Flow version of the famous Sloppy Stage 2 cam. That cam from TFS offered 0.585 lift, a 228/230 degree duration split, and 112 degree LSA. The cam was combined with a dual-spring upgrade from Brian Tooley Racing.

Run with 1-7/8 inch, long-tube headers, the cammed LY6 produced 514 hp at 5,900 rpm and 493 lb.-ft. of torque at 4,600 rpm.

If you are looking to exceed 500 hp with stock cathedral-port heads (we tested 799s on this LY6), it takes a bigger, more aggressive cam to offset the change in head flow (rectangular ports flow near 310 cfm, 799s flow near 250 cfm).

Run with a Comp 469 cam (617/624, 231/247, 113), 799 heads, and Dorman LS2 intake, the 6.0L produced 524 hp and 485 lb.-ft. of torque. Run with this same cam and the rec-port heads, the LY6 produced 543 horsepower—so head flow is every bit as important as cam timing, but now how do we get to 600 hp?

600 Horsepower 6.0L LQ4/LQ9

Coaxing over 500 hp from your 6.0L is not terribly difficult, nor is 550 hp—but when you starting asking the motor to eclipse 100 hp per liter (over 1.64 hp per inch), things get more difficult.

To reach this number, you need more of everything, including head flow, cam timing, and the right intake manifold.

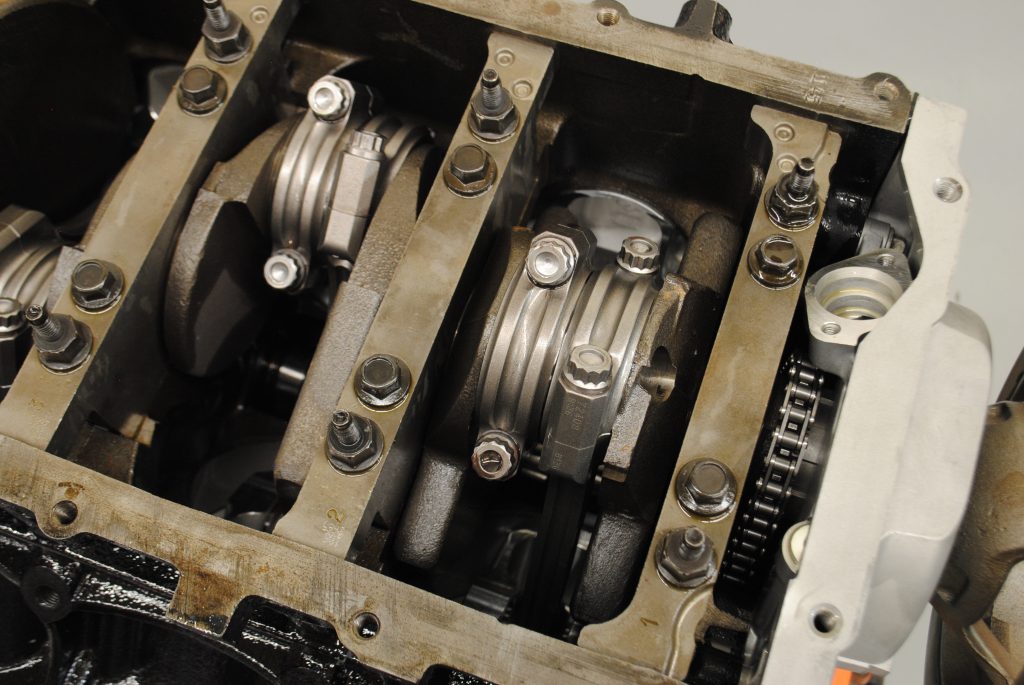

The 600 hp 6.0L not only received these things, but started out life as a complete build up. Where the 400 hp and 500 hp version required nothing more than stock bottom ends, the 600 hp 6.0L featured only a stock iron block and cast crank. To these we added forged 6.125 inch rods and forged flat-top pistons that had generous valve reliefs that provided sufficient piston-to-valve clearance to allow for the necessary wilder cam timing.

Comp Cams supplied the necessary stick, with specs of 0.624 lift, a 239/255 degree duration split, and 114 degree LSA. The cam was combined with a set of AFR LSX 230 V2 heads that provided peak flow numbers of 328 cfm on the intake and 252 cfm on the exhaust. Quality cylinder heads make reaching your power goal so much easier. The finishing touches included a Fast LSXRT intake and 102mm throttle body, 1 7/8-inch headers and our Holley HP ECU.

Run in this manner, the 6.0L produced 596 hp and 501 lb.-ft. of torque.

What would it take to get the extra five or six horsepower to exceed 600 hp you ask? Just install a short runner intake (think BTR Trinity) and you will certainly see 600 hp numbers, though torque production will suffer.

Hello Richard my name is Paul I have lq4 6.0 do you have any recommendations on a good flat top piston and Rod combination and possibly a better cam than the sloppy stage 2 which I’m currently using I’m looking to use the car for a drag and drive event looking to achieve about 600 horsepower possibly a little more with a hundred shot of nitrous car is a Ford Model A weighing approximately 2400 lb

I have a 2010 silverado 2500hd 6.0 ly6. What is the part number for the cam that you installed . The 231/247 cam? Would that be a good cam for my application or is there another cam that would get me close to 600hp without changing alot. Also wat all would I need to change to add this?