If you drive a vehicle with a manual transmission, you’re probably familiar with how a clutch works (if not, read this). In a nutshell, the clutch links your engine and transmission together, and the clutch pedal allows you to control and modulate the engagement of the engine’s output shaft to the main shaft of the transmission.

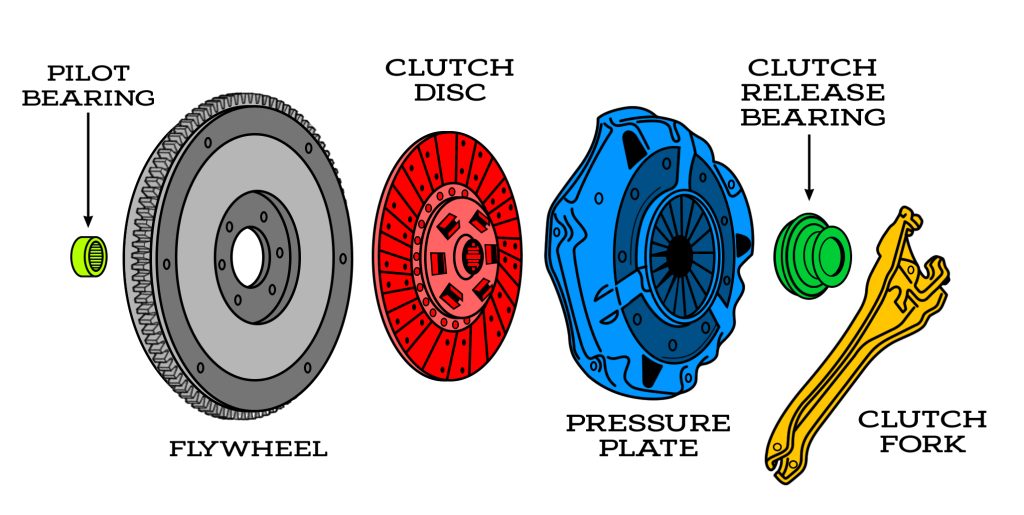

And although the centerpiece of a clutch system is the clutch disc itself, a clutch is often viewed as an assembly of discrete components working together to make your vehicle move.

5 Main Parts of an Automotive Clutch Assembly

- Pilot Bushing or Bearing – Centers & supports the input shaft.

- Flywheel – Provides the mounting & friction surface for your clutch assembly

- Clutch Disc – Connects the engine to the transmission by a splined hub

- Pressure Plate – Applies pressure to a clutch disc or discs

- Release or Throw-out Bearing – Allows the clutch fork to disengage a spinning clutch

For this reason, clutches are often sold as clutch kits that contain some of the wear-prone parts you’ll need to replace when swapping in a new clutch disc. These kits often include parts like bearings, seals, bushings, and sometimes a handy clutch alignment tool to ensure you’re able to easily slip the clutch disc onto the splined input shaft of the transmission.

Key Clutch Measurements

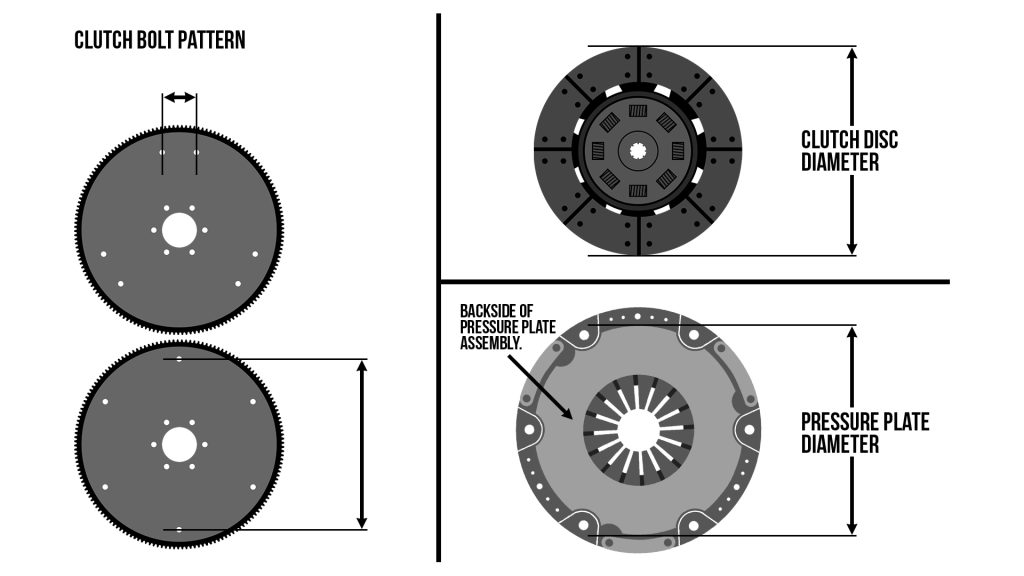

While automotive clutches are typically application-specific to your vehicle’s engine and transmission combination, there are some good measurements to take, so you can be absolutely, positively sure that the clutch disc you’re ordering is correct for your car, truck, or SUV.

And these specs are particularly handy if you’re working on an older vehicle with a non-original (or otherwise unknown) engine/transmission combo.

The first spec is clutch disc diameter, taken by simply measuring across the face of the clutch disc. Knowing your pressure plate diameter is valuable too, and you take that measurement from the backside of the pressure plate assembly.

Be sure to compare those measurements against the clutch you’re ordering.

You may appreciate this article too: What’s the Difference Between Borg & Beck, Long & Diaphragm-Style Pressure Plates?

Comments