How do we make big power on pump gas?

Yes, we can always add boost or nitrous, but what if we want to go the all-motor route? This limits our choices somewhat, but the tried and true (and wholly American) method of adding power is to simply make it bigger!

To put this in LS parlance, if a 4.8L is good, then a 5.3L is even better. We know a 5.3L certainly makes more power than a 4.8L, but why stop there? If a 5.3L makes more power than a 4.8L, then why not step up to a 6.0L, or heck, why not bore and stroke the 4.8L/5.3L out to a 383 or do the same to the 6.0L and make it a 408?

Now you’re thinking—but why stop there?

Why can’t we go even bigger, I mean this is America, right? If a 408 is good, then a 454 must be even better, but what happens when we build these bigger is better combos, and just how much power do they actually make on pump gas? Well folks, we have two examples of bigger is better here, the first being a more common 408 stroker then a slightly wilder 454 stroker!

Let’s take a look at the two stroker combos and how they performed.

408 LS Stroker Engine Build & Dyno Test

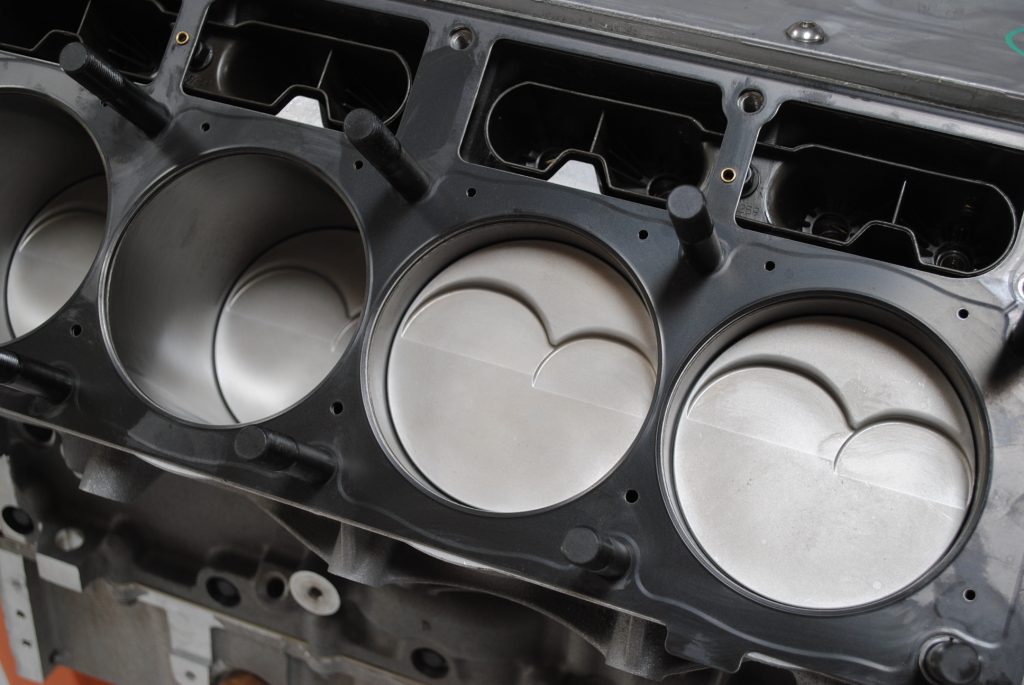

First up was the 408 stroker, which was achieved by starting with a 6.0L iron block from an LQ4. Sure, you can build a 383 stroker by boring a 4.8L/5.3L block out to 3.905 then adding a 4.0 inch stroker crank, but if you stuff the same 4.0 inch stroker crank in a 0.030-over 6.0L block, you get 408 cubic inches!

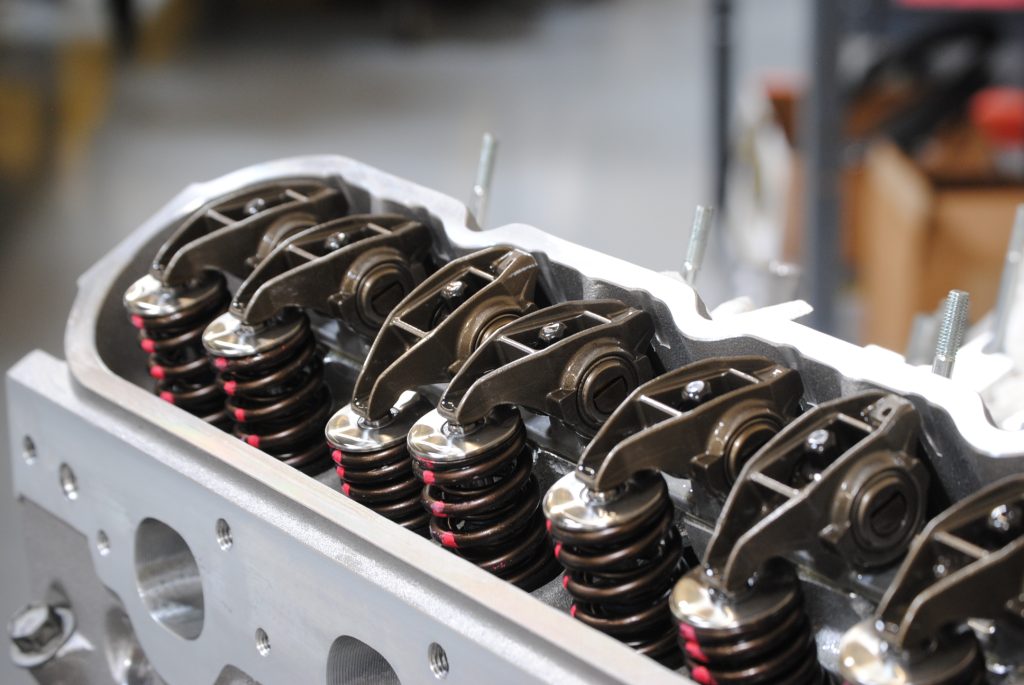

The 4.0 inch forged Scat stroker crank was combined with 6.125 inch rods and custom 10cc dished pistons to create a 10.7:1 408 short block. The stroker received a Crane hydraulic roller cam that offered 0.600 lift (intake and exhaust), a 240/248 degree duration split, and 114 degree LSA. The cam was teamed with standard-travel Comp lifters 0.080 wall, hardened pushrods, and stock rockers.

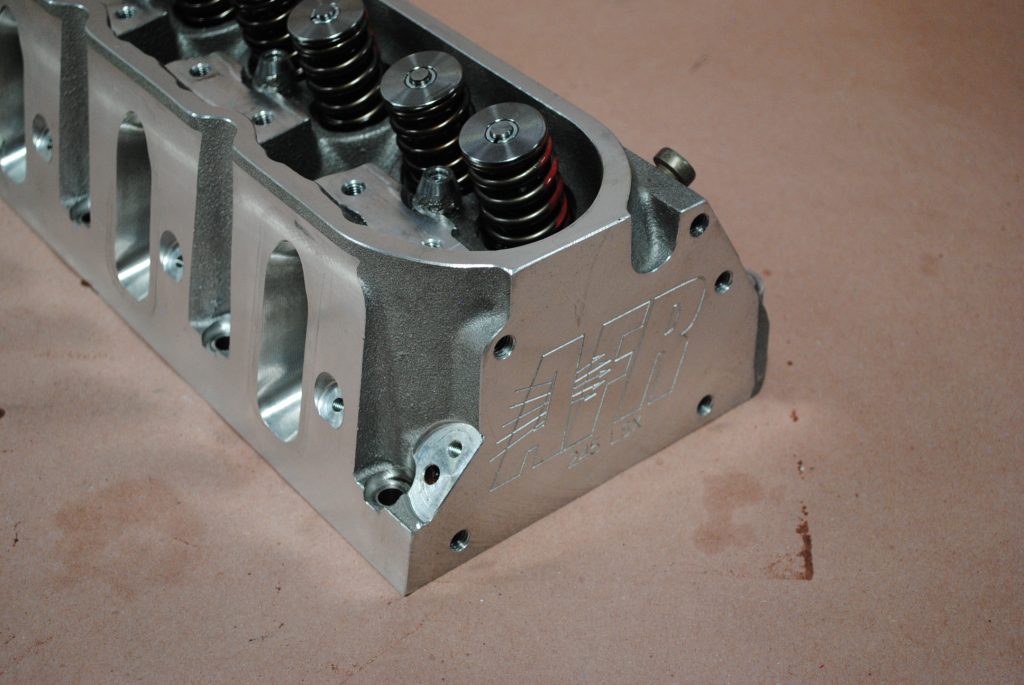

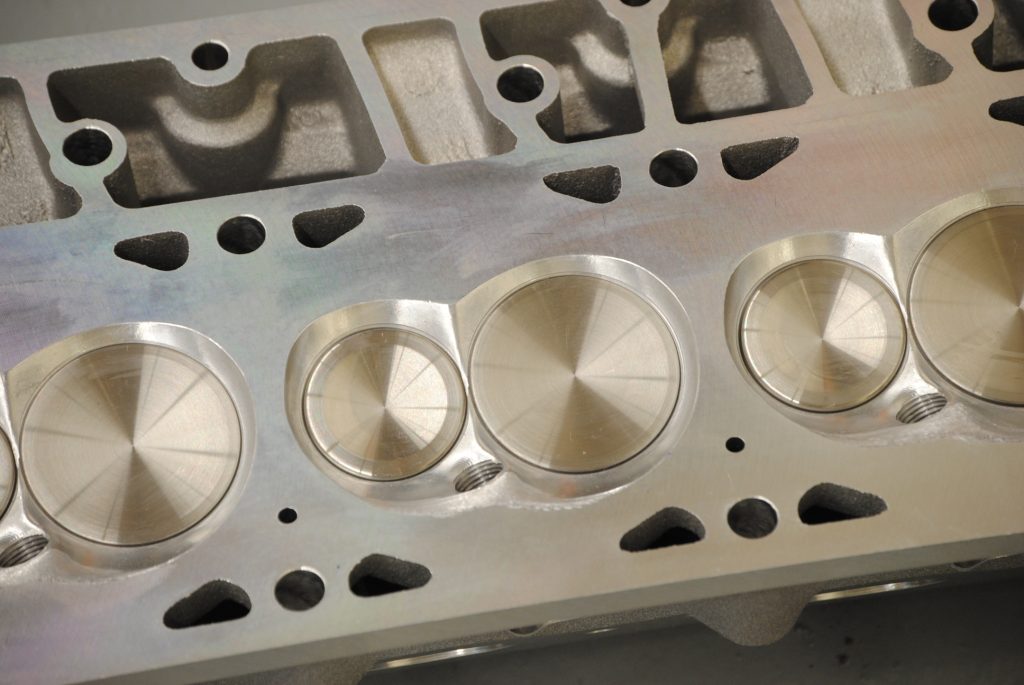

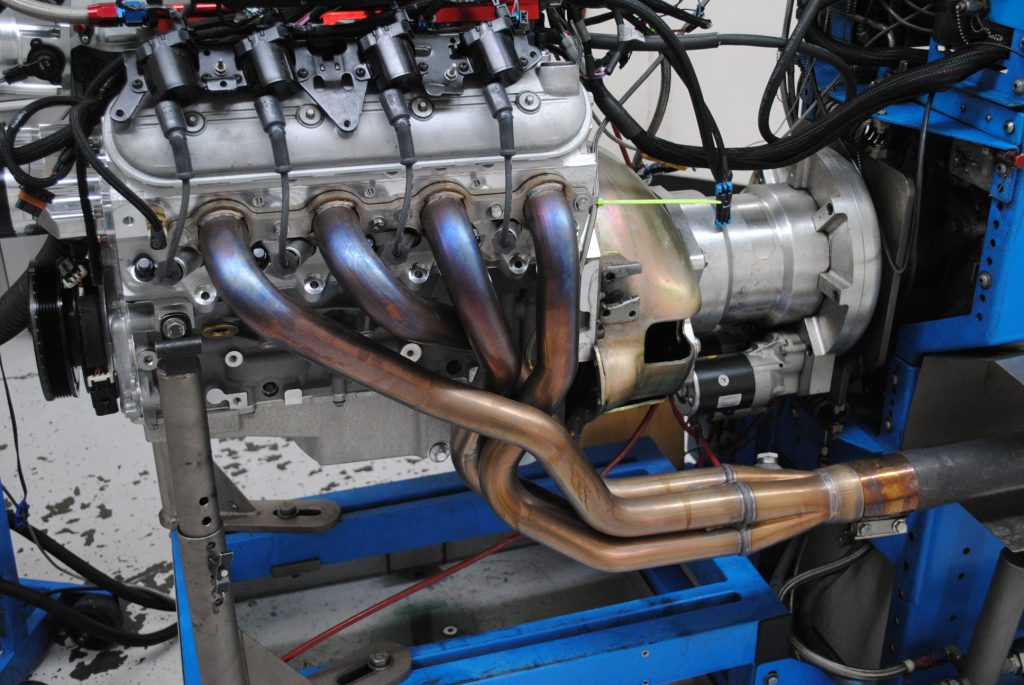

Naturally a healthy cam required plenty of head flow, so this 408 stroker received a set of AFR 245 heads. The AFR 245 heads featured full CNC porting, a 2.165/1.60 valve package and (in our case) 65cc chambers—which meant they were actually emissions legal on pre-2005 applications. Finishing touches included a FAST LSXR intake manifold and matching FAST 102mm throttle body, 1-7/8 inch, long-tube headers, and a Holley HP management system.

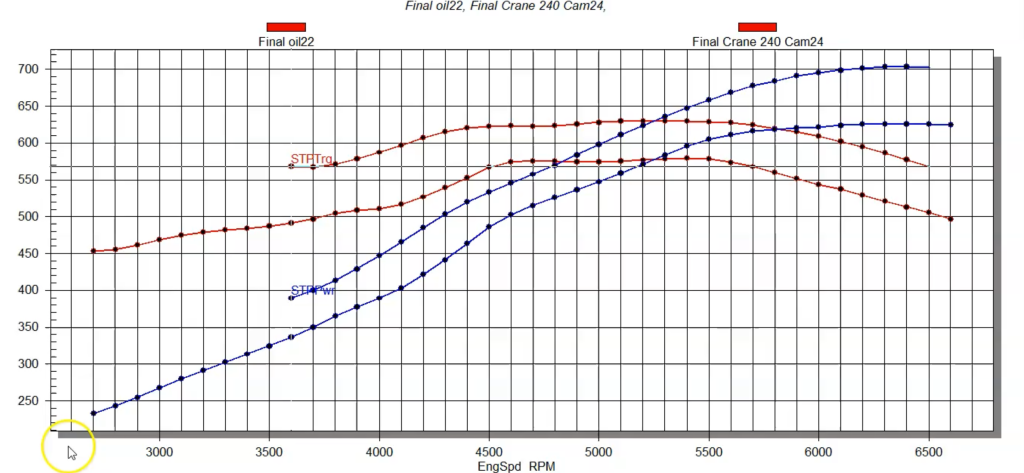

In truth, this 408 was run with a number of different cams and heads and intakes—but in this configuration, the 408 thumped out 626 hp and 580 lb.-ft. of torque using 91 octane pump gas.

For you math folks out there, that equates to 1.53 horsepower per cubic inch!

454 LS Stroker Engine Build & Dyno Test

The 408 stroker turned out very well, but if a 408 is good, then shouldn’t a 454 be even better?

The answer is obviously yes, but how did we achieve the 454 displacement? The key elements in displacement are bore and stroke, and in the case of the 454, we (meaning Brian Tooley at Brian Tooley Racing) increased both.

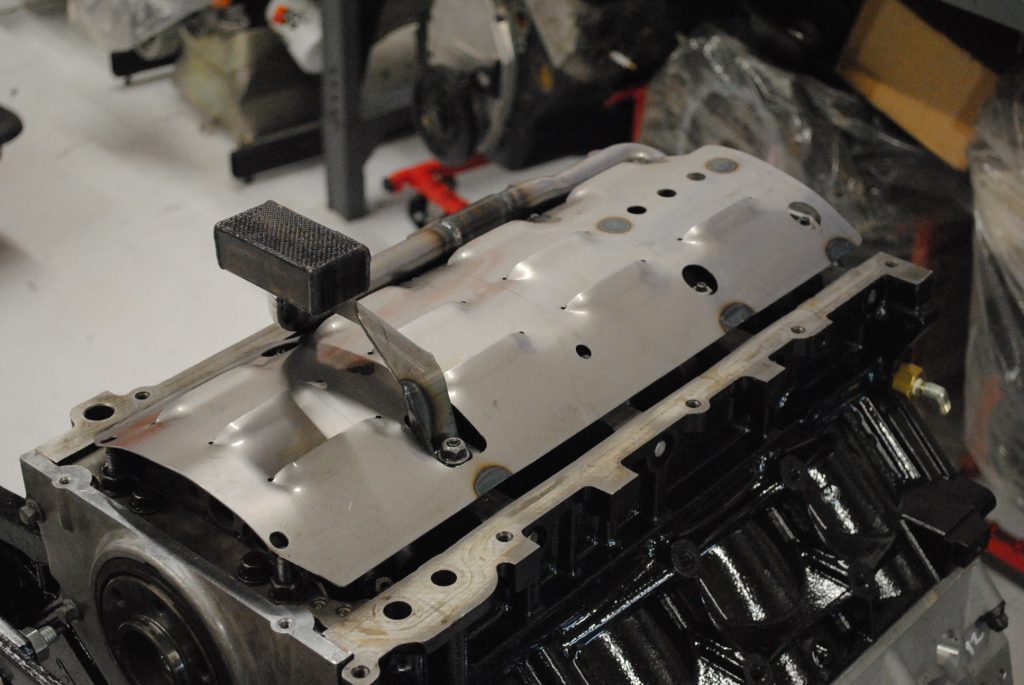

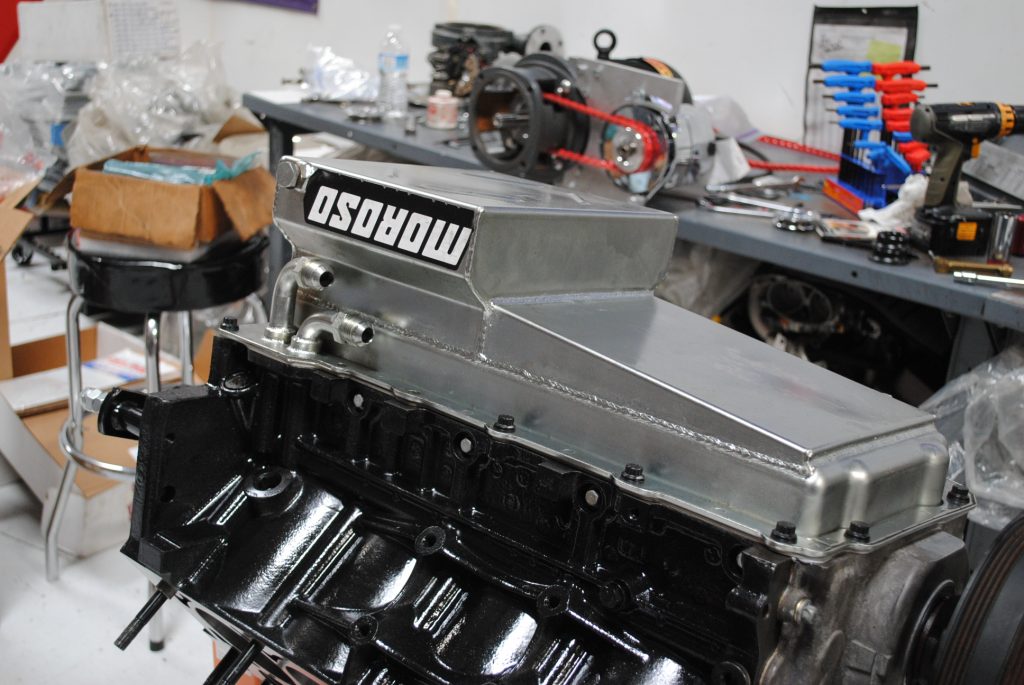

Increasing the bore was a simple matter of selecting the factory LS7 aluminum block, which came factory fresh with a 4.125 inch bore. This alone increased the displacement, but the longer sleeve length in the LS7 block also allowed for the installation of a longer stroke, in this case up to 4.250 inches.

The shorter sleeve lengths in the other factory blocks (like the iron LQ4/LQ9 used on the 408 build) will not accept the 4.25 inch stroker crank without fear of pulling the piston too far out of the bottom of the cylinder bore. It doesn’t actually come all the way out—it just comes out enough to allow piston movement (rocking) that can upset proper ring seal.

We don’t recommend stroker cranks longer the 4.0 inches in stock LS blocks (other than the LS7) without first sleeving the block.

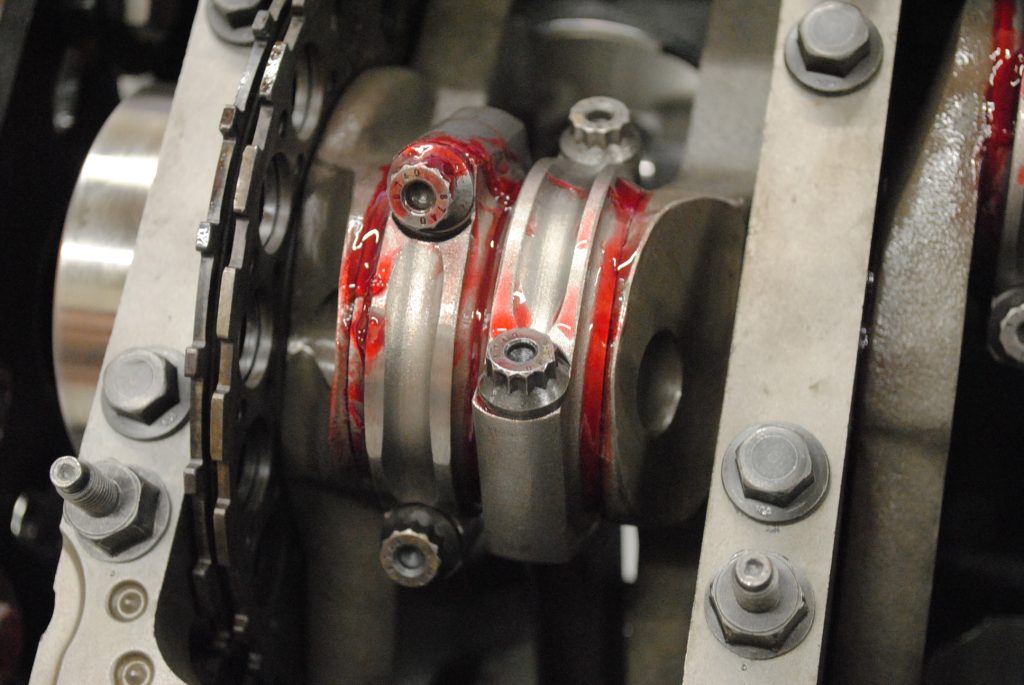

The LS7 block then received a Wiseco forged rotating assembly that consisted of the 4.25 inch stroker crack, 6.25 inch rods, and forged flat-pistons that produced a static compression of 12:1.

How did the 12:1 454 run successfully on 91 octane pump gas you ask? Read on!

To make power, the 454 was naturally equipped with the proper cam and induction system. Starting with the cam, the hydraulic roller (remember street car) cam offered 0.660 lift, a 251/266 degree duration split, and 115 degree LSA. The cam was teamed with shimmed LS7 lifters to effectively produce short travel versions.

Feeding the cam was a set of modified TFS 245 cathedral port heads and ported FAST LSXR intake. In addition to full CNC porting, mods to the TFS 245 heads included smaller exhaust valves and a 50 degree valve job (nitrous exhaust port).

The heads were also treated to relocation of the rocker bolts for use with 1.8 ratio, LS7 rockers and softening of the chambers to allow the elevated static compression on pump gas. The enhanced TFS 245 heads featured a 2.10/1.58 valve package and 70cc chambers, with peak flow numbers of 353 cfm on the intake and 278 cfm on the exhaust.

Other tricks included 1/2 inch head studs, 3/8 inch pushrods, and a ported LS6 oil pump. The FAST intake was disassembled and fully ported, and the combo was run with 1-7/8 inch long-tube headers.

Run on 91-octane (California fuel), the 454 eventually produced 704 hp and 630 lb.-ft. of torque, with torque production exceeding 600 lb.-ft. from 4,400 rpm to 6,100 rpm.

The 704 hp offered a slightly better specific output than the 408, with 1.54 horsepower per cubic inch.

Kool

Does anyone have the correct part number for the camshaft?

Hey Michael, it looks like it was a Brian Tooley BTC-32744155, but it’s now gone N/A. You can contact the Summit Racing tech experts though, they’ll be able to recommend a great alternative camshaft for your application.