I’ve got a nice 3310 Holley 750 cfm vacuum four barrel carb for the 350 small block Chevy in my El Camino that I want to use because I think it’s a good carburetor—but a couple of my friends think I’d make more power and be happier with a 750 cfm Holley double pumper carburetor. Is there much of a difference? They tell me that I’ll be much happier and make more power but I’m leaning toward keeping the 3310. Your thoughts?

C.D.

***

It’s interesting how gearheads have very decided opinions on lots of car topics that have very little connection to what is actually happening. I suspect that when folks bag on a particular carburetor (like calling a Rochester Q-jet a Quadra-Bog), what they are really telling you is that they don’t understand even the simplest of processes that make a carburetor work. Instead of learning to tune and massage a carburetor, they just throw up their hands and claim it’s junk.

I saw a great quote the other day that claimed “I became a tuning wizard because I spent a little time reading and learning.”

To address your question, if Holley rates its carburetor at 750 cfm, there is very little difference in airflow between a mechanical secondary or a vacuum secondary carburetor. The fact checkers will immediately point to the AI reference on Google that claims a vacuum secondary carb will be lower because it is slower to respond. The problem with that analysis is that it’s possible the engine didn’t really need 750 cfm to begin with, which would then mean the secondary may not open fully because the engine doesn’t need all that airflow.

So based on pure cfm, we might assume there would appear to be no power difference between those two carburetors. I think many enthusiasts choose a mechanical secondary carburetor because it is easier to understand how it works.

A vacuum secondary Holley is slightly more complex. But only slightly.

Understanding How Vacuum Secondaries Work

The term vacuum-operated secondary is somewhat confusing because intake manifold vacuum plays no part in its operation. A vacuum secondary Holley works when the primary throttles open to generate sufficient velocity through the venturis. There is a very small hole or sometimes a tiny brass fitting located in the passenger side primary venturi that senses this velocity. The air passing past this hole creates a vacuum signal. The hole in the primary side is connected though a passage to the vacuum canister bolted to the passenger side of the carburetor. Inside this canister is a large rubber diaphragm molded to a rod that connects to the secondary throttle shaft.

As engine speed increases and higher velocity is achieved in the primary side, this creates sufficient vacuum in the passage to overcome the spring located on top of the diaphragm that holds the secondary throttle shaft closed. The large diameter of the diaphragm uses atmospheric pressure below the diaphragm to overcome the spring pressure aided by the vacuum above the diaphragm, which helps moves the diaphragm up to open the secondary throttle blades.

There are several variables that affect how quickly the secondaries open relative to engine demand. First, most Holleys use a small steel check ball in the passage to help manage the secondary throttle opening rate.

More importantly, Holley offers several different color springs that are the main tuning tools for changing the secondary opening point.

Understanding Vacuum Secondary Springs

All Holley vacuum secondary carburetors are shipped with the heaviest black spring in the secondary canister. This heavy spring delays the opening of the secondaries. Holley does this because they don’t know how the carburetor will be used. It might be used on a high output 454 big block Chevy or just as likely on a little 289 small block Ford with a mild cam.

To ensure the secondaries do not open too soon and cause a hesitation, Holley chooses the conservative approach with the slow opening black spring.

Because of this slow opening spring, there have been several hacks over the years to overcome this by mechanically opening the vacuum secondaries. The most common hack is to place a sheetmetal screw into the slot to force the secondaries open after a small amount of primary throttle shaft movement. This always results in a slight hesitation or bog when the throttle is quickly slammed open because vacuum secondary Holleys are not equipped with secondary accelerator pump.

The reason why vacuum secondary Holleys are not equipped with an accelerator pump—or squirter—on the secondary side is that the system is designed to open the secondaries only after sufficient air velocity opens the secondary throttles. This allows the boosters to initiate fuel flow quickly and a secondary pump shot is not necessary.

Mechanical secondaries use an accelerator pump to cover up a lean condition that can occur when the secondaries are opened too soon and there is insufficient velocity through the secondary side to initiate fuel flow through the secondary boosters.

Basically, this screw hack (or sometimes a zip tie) placed in the secondary travel slot does not work well. Sure it mechanically opens the secondaries but it also causes a big hesitation when the throttle is jammed open prematurely because of the insufficient airflow past the secondary boosters.

The smarter move to improve the secondary opening rate is to experiment with different vacuum secondary springs. We’ve included a chart that lists the springs in terms of lightest to heaviest. Our experience is that either the plain or purple springs tend to work the best but each application is different and will require experimenting to find the ideal spring. If during testing of a light spring you notice anything that feels like a hesitation, then the spring is too light and opening the secondaries too soon.

Holley Vacuum Secondary Spring Kit Color Code Ratings

| Color | Rating |

|---|---|

| White | Lightest |

| Yellow (short) | Lighter |

| Yellow (tall) | Light |

| Purple | Medium Light |

| Plain | Medium |

| Brown | Medium Heavy |

| Black | Heavy |

How to Swap Vacuum Secondary Springs

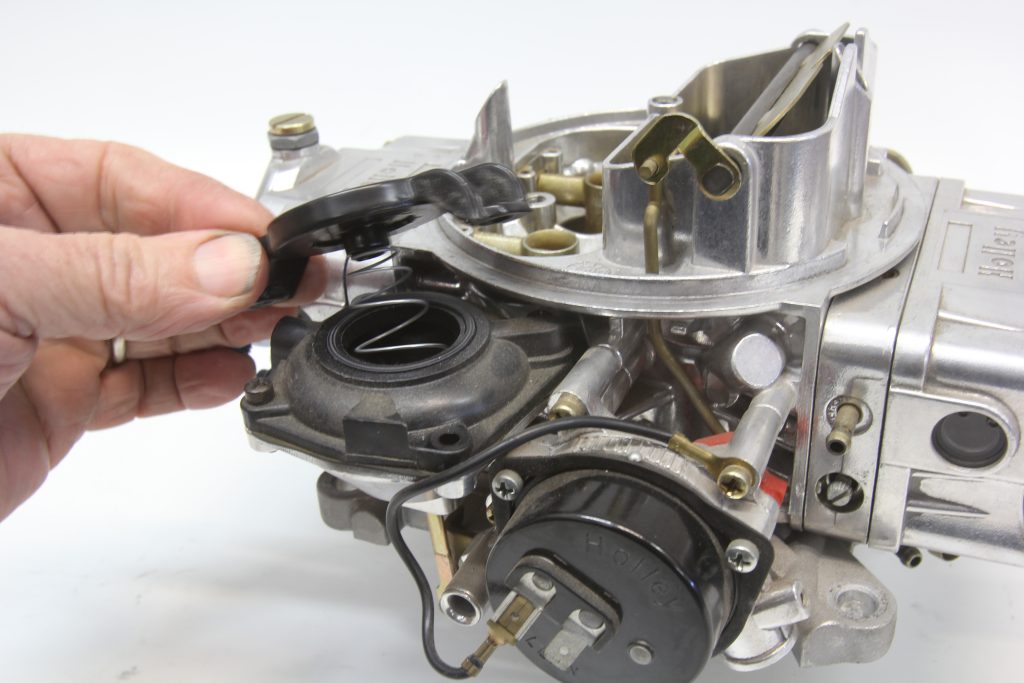

Changing these diaphragm springs is a challenge. The main problem is that the four tiny screws can catch the edge of the thin rubber diaphragm and during tightening can tear the thin rubber and render it useless.

To combat this problem, Holley developed a quick-change lid that allows you to change the spring without having to remove the entire lid but instead just a small opening in the top allows changing the spring. This kit works exceptionally well and we’d recommend it for any vacuum secondary Holley. Or if you have a ton of canisters laying around, you can fit teach canister with a different spring, mark the canister and merely exchange them to tune the car. That’s how we did it back in the old days before the quick change kit came about.

A long time ago, a bracket racing friend told us that his low 12-second small block Camaro was more consistent and had a quicker 60-foot time using a vacuum secondary 750 cfm Holley compared to the same cfm mechanical secondary Holley. Of course this was after quite a bit of tuning to get the vacuum secondary to open at just the right time but it does reinforce that a vacuum secondary carburetor can work just fine if you are willing to put in the time to tune it properly.

Vacuum Secondaries Tuning Parts List

- HLY-20-13 – Holley vacuum secondary spring kit

- HLY-20-59 – Holley quick change diaphragm cover kit

- HLY-108-67-20 – Holley cork gasket seal

- HLY-135-4 – Holley vacuum secondary diaphragm (0-3310)

- QFT-631QFT – Quick Fuel adjustable vacuum secondary housing

Great article. You brought to the service of the mindset of many people who don’t have the knowledge on tuning or select a carburetor.

I.E. it doesn’t run right so the carburetor is a pos.

Use a mechanical secondary carburetor over vacuum even if it’s a mild or stock rebuild etc.

It depends on your combination, but Jeff is right. If you tune the vacuum carbs properly there is no reason to use a mech carb on most street cars. But again it is in the combination. Everybody has a different opinion on what is really a street car and that is where the problem can start. I run deep ten second quarter miles consistently and drive the car everywhere with tri power vacuum Holleys for years with no problems ever!