After spending countless hours researching wheels and tires for the right look and fitment, they’ve finally arrived and it’s time to install them.

Let’s review installation tips and procedures for safe, trouble-free operation.

Stock, Aftermarket & Custom Wheel Installation Tips & Techniques

If you’re reusing wheel studs, carefully inspect their condition. If needed, clean rusty or dirty threads with a wire brush and/or thread chaser.

If you suspect the studs have been previously over-torqued, fatigued, or if the threads are distorted in any way, replace them!

When replacing studs, make sure they’re fully seated. Don’t rely on lug nut torque for proper seating—use a proper wheel stud installation tool. It’s always recommended to use new lug nuts with new wheels; some wheels have smaller-diameter recessed holes and will require spline-drive lug nuts.

Test fit each wheel in its final position. Ensure the bolt pattern matches and the wheel makes full contact with the hub mating surface.

To prevent rust and seized wheels, you can apply a thin coat of anti-seize lubricant around the hub center.

Install the new wheels and hand-tighten the lug nuts. Carefully confirm they rotate freely and don’t contact brake or suspension components.

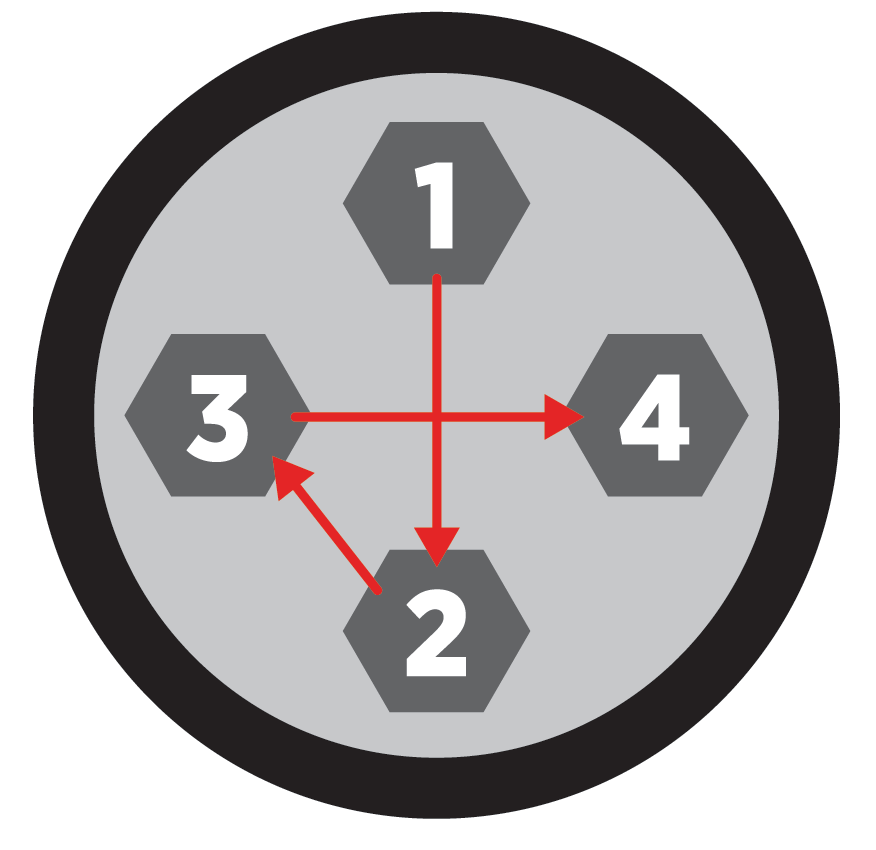

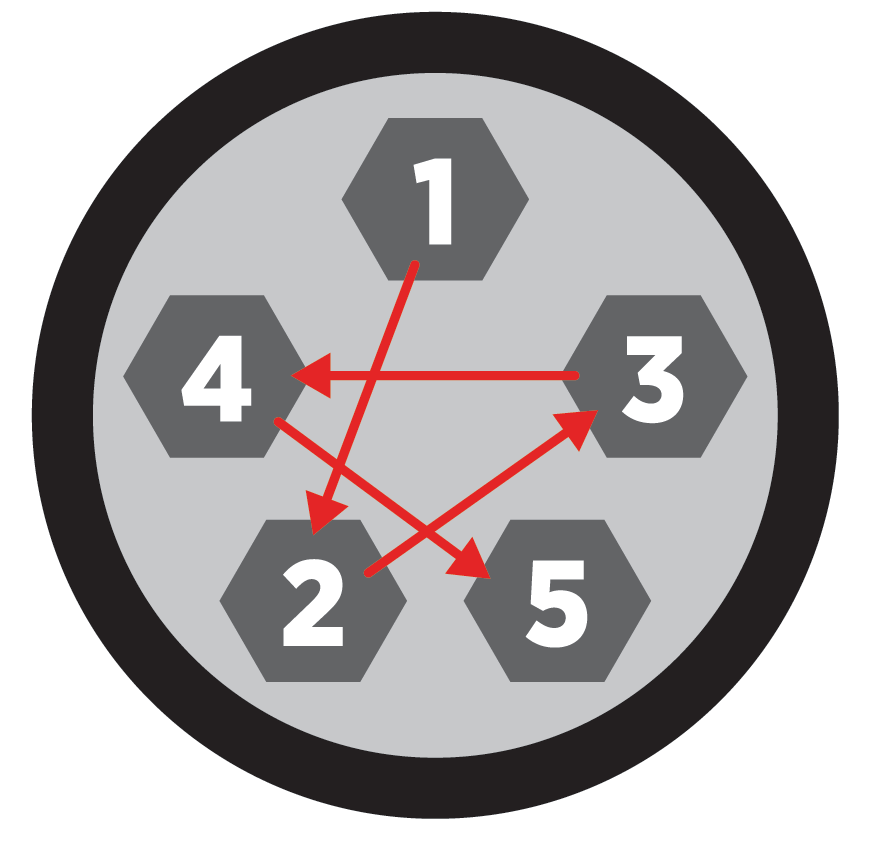

Using a quality lug nut socket and an accurate torque wrench, tighten all the lugs to half the total torque value in a star pattern. Then, finish tightening all the lugs to the manufacturer’s torque spec, repeating the same pattern; this will help to ensure that the wheels are centered on the hub as intended.

Do not use an impact gun to tighten lug nuts!

Lug nuts should be re-torqued after the first 50 to 100 miles, especially with new wheels or when studs are replaced. If you cannot find the recommended torque spec from the vehicle’s manufacturer,

you can use the following chart as a general guide.

Recommended Lug Nut Torque Specs

| Stud Size | Torque Spec |

|---|---|

| 7/16″ | 55 to 65 ft.-lbs. |

| 1/2″ | 75 to 85 ft.-lbs. |

| 9/16″ | 95 to 115 ft.-lbs |

| 5/8″ | 135 to 145 ft.-lbs. |

| 12mm | 72 to 80 ft.-lbs. |

| 14mm | 85 to 95 ft.-lbs. |

***

Lug Nut Torque Tightening Patterns

***

4 Lug Nut Torque Tightening Pattern

5 Lug Nut Torque Tightening Pattern

6 Lug Nut Torque Tightening Pattern

8 Lug Nut Torque Tightening Pattern

Comments