Honestly, I never knew what a torque limiting socket extension was until the folks from Summit Racing asked me to review a set of its own brand of extensions. I found out that a torque limiting extension acts as a torsion device by flexing once a certain amount of torque is applied to the fastener as it is tightened. This helps prevent over-tightening the fastener, particularly when using an impact wrench. Just insert the appropriate extension on your breaker bar or impact wrench and tighten away. It’s all rather clever.

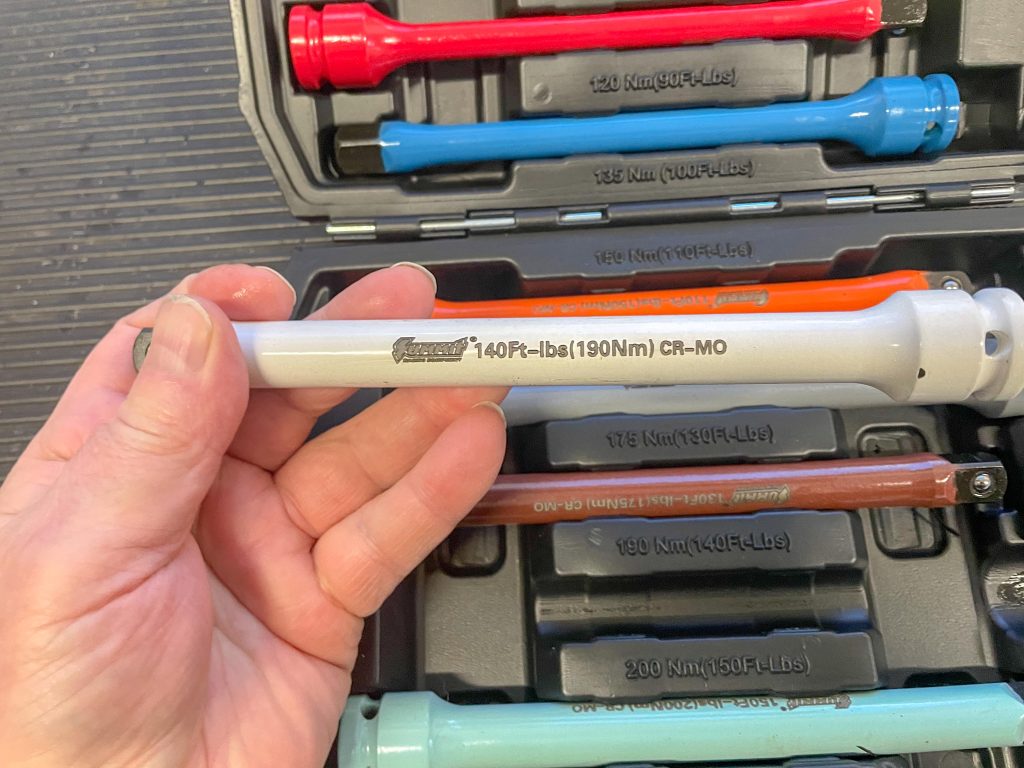

The Summit Racing™ Torque Limiting Extensions are available in a set of 1/2-inch drive chromoly steel extensions color coded by torque limit. The torque range goes from 65 up to 150 ft.-lbs. Each extension size has a different shaft diameter. The thinner the shaft, the less torque it will apply to a fastener. Summit Racing also has a 15 ft.-lb., 3/8-inch drive extension that is perfect for beadlock wheel bolts.

Where torque limiting extensions are absolutely ideal is when you have a lot of similar fasteners that must all be tightened to a specific torque figure. For me, that means lug nuts. Four wheels times five lugs equals twenty turns. Add a couple more turns for lug nuts on aluminum wheels, which should be re-torqued a couple of times following installation. It’s far easier to have an impact gun or breaker bar with a torque limiting extension instead of carrying around a big, somewhat fragile torque wrench with you to double check lug nut torque.

Other places you can use torque limiting extensions include body (cab) mounts or locations where you can’t easily swing a torque wrench, but an impact wrench will work.

Initially, I was slightly skeptical, so I came up with a simple test. The lug nut torque spec form my 1970 Nova is 65 ft.-lbs. on the front (7/16-inch stud) and a bit higher on the rear (1/2-inch drag race stud). I used a breaker bar with the green 65 ft.-lb. torque limiting extension to tighten the front lug nuts. I kept tightening until the extension stopped flexing, indicating I reached the torque limit. I had no desire to feel the stud go “soft” or hear it snap from overtightening.

I then used a beam style torque wrench to verify. I used this style wrench as it would show me a torque range I could actually see. A clicker torque wrench only provides a yes or no answer to the torque reading. It turned out I was a a bit short of 65 ft.-lbs. but nothing major. I suspect if I hadn’t been so concerned about killing a wheel stud, the torque reading would have been even closer. I think the extensions will work similarly well with an impact wrench.

In my opinion, these are definitely worthwhile tools. They’re not expensive and are well built. Would I use them for something that needs 100% accuracy, like main bearing caps on an engine? Probably not, but that’s not the target for these tools. For a better look, check out the accompanying photos.

Comments