Procrastination usually reigns supreme. I’m good at it. When last year’s drag racing season ended, I’m willing to bet a lot of you just dropped the car in your shop or left it in the trailer and didn’t give it any more thought. Honestly, you can’t be blamed. Who can think about pounding gears when the temperature gauge is below zero and the wind is howling?

Allow me to make a gentle suggestion: give your race machine a good going-over early in the off-season instead of waiting until the week before the local track opens. That will give you time to inspect the car and replace worn parts or fix hidden damage you didn’t see when you put it away.

As we get closer to the season opener(s) across the country, chassis builders and other shops will start backing up with work. The earlier you can have the work you need done, the better.

Think about parts availability too. Parts you might need could be on backorder. Some high performance manufacturers now build parts to order instead of having them on the shelf. That could mean a lengthy delay while your stuff is being made.

In this article, we’ll give you a checklist of things to look for when inspecting the chassis and suspension. Engines and drivetrains are a whole ‘nother can of worms that we won’t get into here.

Front End

The front suspension and steering on a race car takes a beating. There’s usually a lot of travel and the car gets a real pounding when it comes down from a wheel stand. Watch the end of a wheelie in slow motion and you’ll know exactly what I’m talking about.

- Inspect every piece on the suspension and steering and replace any item that’s suspect. That includes ball joints, idler arm, pitman arm, control arm bushings, rack and pinion boots and so on. Double check the torque on each fastener too.

- Grease the front end. The front end usually has the most lubrication points on a race car.

- Inspect the front wheel bearings. Repack and adjust them if they check out or replace them if they’re suspect. Bearings definitely take abuse during “landings”. Use a high quality wheel bearing-specific grease like Timken Wheel Bearing Grease. There is a difference.

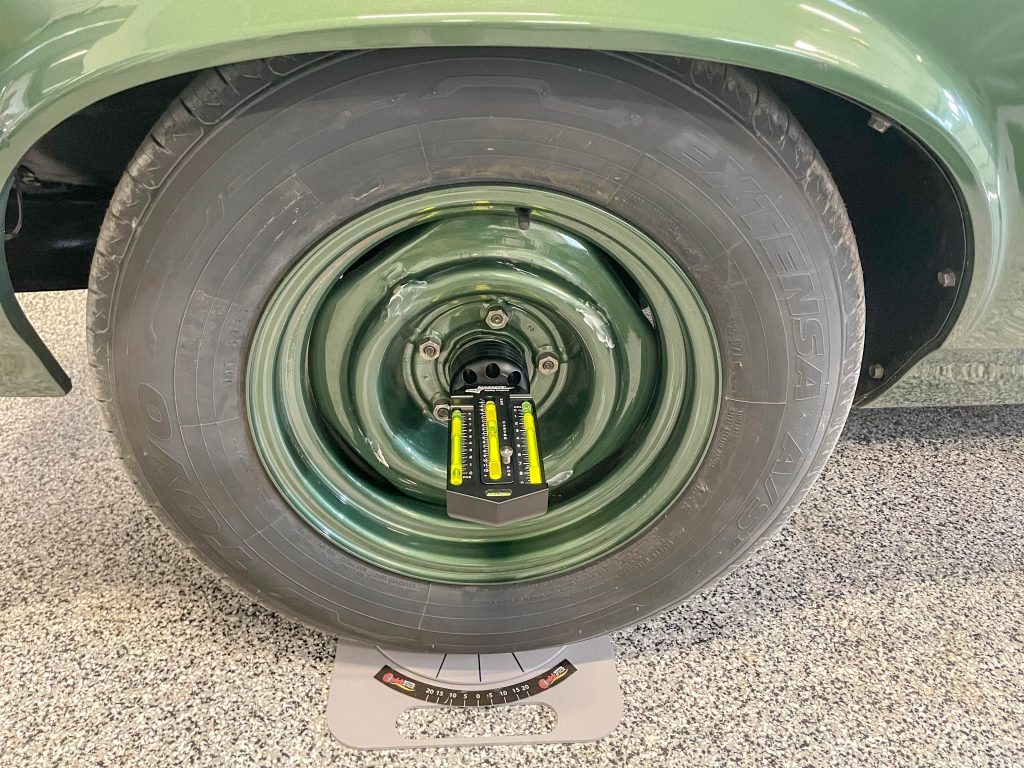

- Do a wheel alignment or get one done. Companies like Quick Trick Alignment have the tools you need for a DIY alignment. You don’t need a wheel alignment rack either.

- If you have a good set of adjustable shocks that have some race miles on them, this is the time to send them off for a rebuild if necessary. As we pointed out previously, don’t delay if this is in your game plan for the season. Shock specialists get super busy super-fast.

Rear Suspension

Whether your rear suspension is simple or exotic, there are a lot of wear items that tend to get ignored or forgotten during race season. That means here could be a lot of work to do.

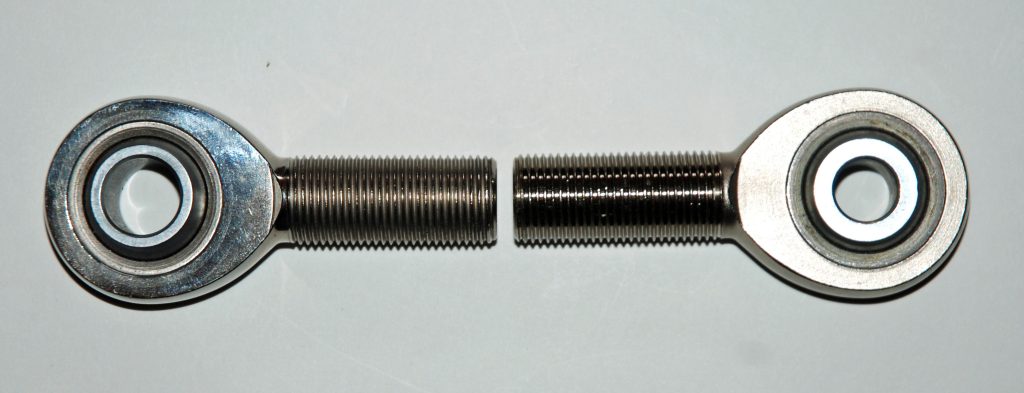

- Inspect every single piece of the suspension. That includes removing each rod end to check for bent shafts or worn races. Replace rod ends as necessary. Good quality rod ends are expensive, but this is one place where you should use the best parts you can afford. I use FK rod ends. They’re made in the are USA made and awesome quality.

- Lubricate any components that are greaseable. Once again, use high quality grease.

- Check alignment. Here we’re talking about “square” to the chassis. If something is bent, you’ll never get it square. Now’s the time fix the problem if one exists. Make sure there’s no binding in the suspension either.

- Check and reset suspension settings to your baseline (you do have a baseline written down, don’t you?). Once you’ve inspected and possibly replaced suspension pieces, you might find the settings are a bit off.

- The rear shocks also take a big hit. Now would be a good time to get them rebuilt and/or revalved if necessary.

- Check the torque! Every fastener should be torqued. Also, many drag race style rear suspension pieces have Nyloc nuts and they don’t last forever. Replace any suspect ones just to be safe.

Brakes

Brakes often get relegated to the “If it ain’t broke, don’t fix it” list. Don’t do that. You might be surprised at the amount of wear brake components get in a drag race application. Slowing down from warp speed on a track with a short shutdown can definitely make you swallow your bubble gum, so good brakes are a must.

- Inspect rotors and pads and replace as necessary. Brake pads for drag racing usually have a soft compound that works great when cold and can help you when foot braking. Soft pads wear quickly, so replace them each season.

- Look for leaks. Sometimes it’s just a matter of tightening a fitting, but in some cases you might be forced to replace hard line. Seals (wheel cylinders are good example), can give up the ghost too. If anything looks even partially damp, investigate the cause and replace parts as necessary.

- Examine brake hoses very carefully! Rubber brake hoses typically rot from the inside out. That means you won’t see deterioration until it’s too late. You really don’t want too late to be when you’re at the top end trying to bring your car down from speed.

Brake fluid degrades over time and with hard use. It’s a very good idea to replace it and re-bleed the system.

Wheels & Tires

Few will argue that slicks or drag radials will likely need some attention. Bu there the rest of the rolling stock needs to be inspected and quite possibly replaced before the season begins.

- Inspect wheels for cracks. Examine the areas between wheel halves closely and take a close look at the wheels adjacent to the lug nuts. Cracking is more common than you might think, especially with flyweight drag wheels.

- Inspect lug nuts and wheel studs. Studs with damaged threads should be replaced. Lug nuts with any sort of damage should also be replaced. When the inspection is over, be sure to torque to specification.

- When inspecting slicks or DOT radials, make sure to check the wear indicators. Also consider the age of the tires. If your car has been parked for a few years, you might find they’re beyond their best-before date.

- In many situations when breaking out can determine the winner or loser of a race, the front rolling stock takes a pounding. Inspect the front tires and replace as needed.

Comments