What factory cylinder heads should I run on my 6.0L LS?

The question is somewhat loaded, as the answer depends on your desired outcome. Are you looking to maximize low-speed towing torque, or do you want said 6.0L to charge hard on the big end? Is it a daily driver with a stock converter or is it a street/strip weekend warrior?

Obviously, the other components (like cam and intake) also come into play here, but most folks just want to know how the different (cathedral and rectangle port) factory heads perform, and then how they compare to a good set of aftermarket cylinder heads.

Sure, we expect aftermarket heads to outperform stock heads, or why would they have gone to all the cost of making them? But how much better are they? How much power do we get for our hard-earned money?

The only real way to find out how they all perform is to run them back to back on the same motor, but as with any test, there are always “other” changes that become necessary when comparing even factory heads. Get those comments ready!

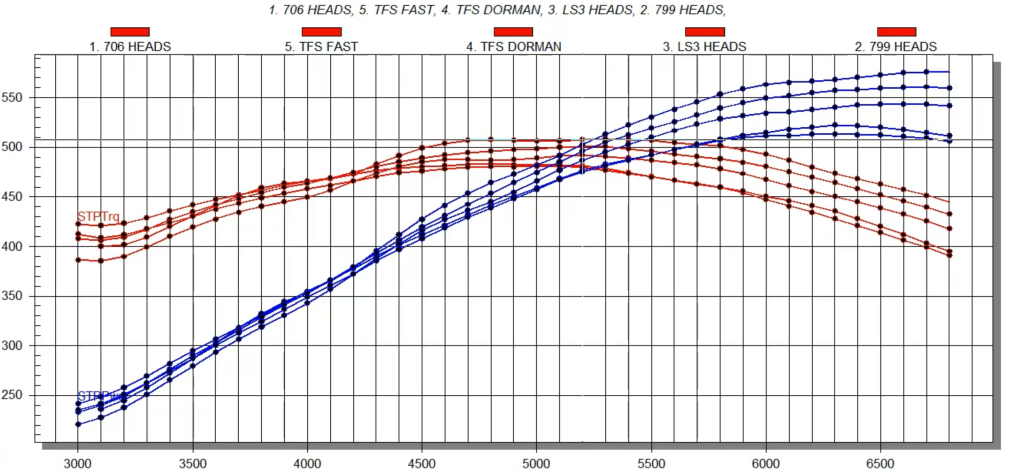

GM LS Engine Cylinder Head Comparison Test Parameters

For this test, we lined up four different sets of cylinder heads. This list included stock 706/862 heads (used on the small-bore 4.8L and 5.3L motors) and a set of 243/799 heads (used on both the small-bore motors and larger 5.7L and 6.0L versions). Rounding out the stock heads was a set of rectangle port 821/823 heads, since they came factory on our 6.0L LY6 test motor.

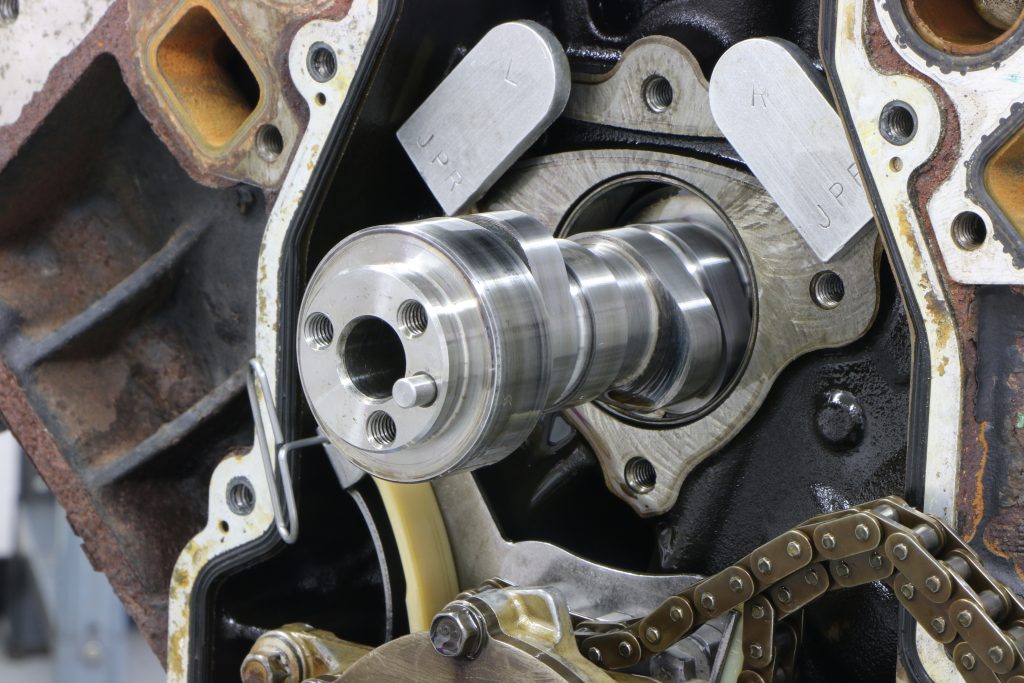

Naturally, the rectangular port heads required a few other changes in the test, namely offset rockers (not really a big deal since they shared the same rocker ratio as the cathedral port rockers), but the rectangular port heads did require a different intake manifold. For this test we used an LS3 intake, though it bears mentioning that the LY6 (truck) intake was also tested and produced an identical power curve to the lower-profile LS3.

The 706, 799, and TFS 225 heads were all run with a Dorman LS2 intake, which my previous test showed produced an identical power curve to the factory TrailBlazer SS (TBSS) intake.

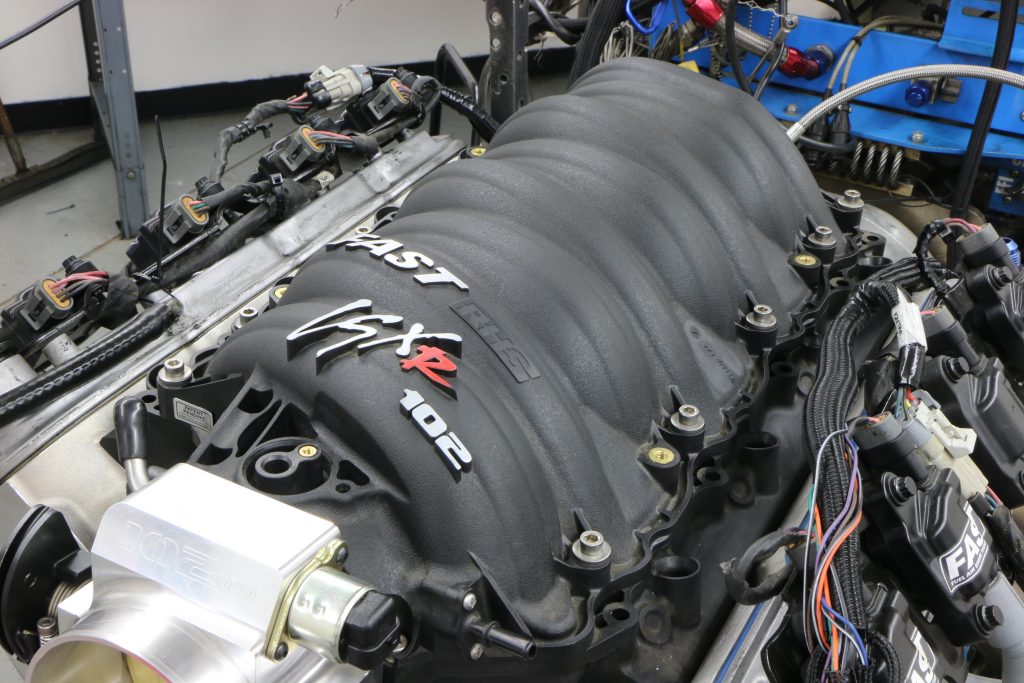

To conclude the test, the most-powerful (not surprising spoiler alert) TFS heads were also run with a FAST LSXR intake. For the rectangular port folks out there already crying foul: a FAST LS3 intake adds no power over the factory LS3 intake (but ported rectangular ports would have been interesting).

The Baseline

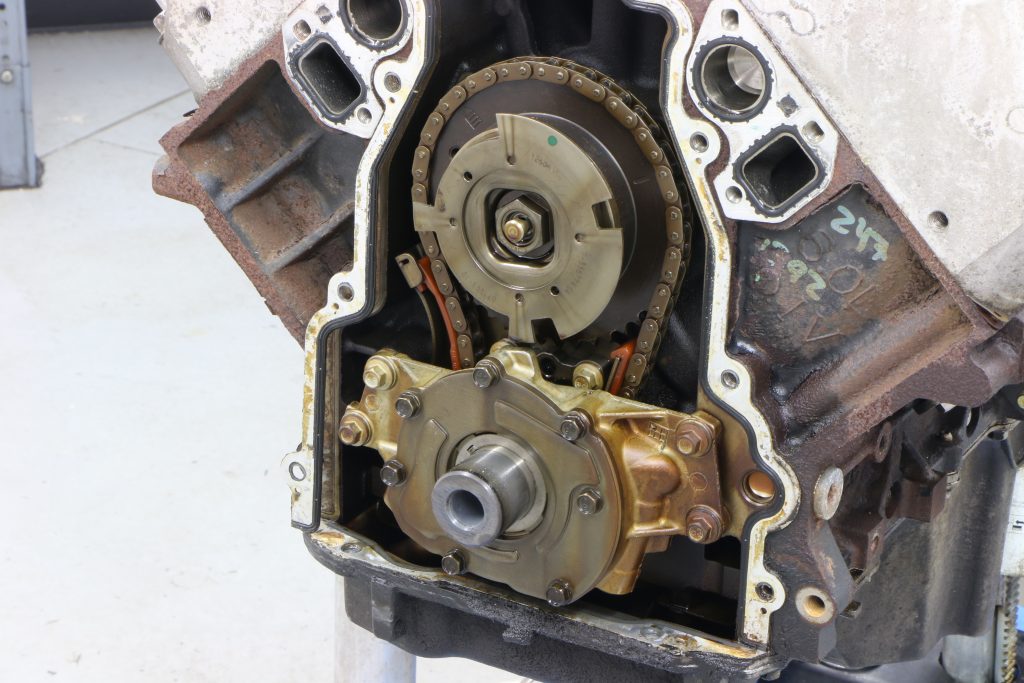

To kick things off, we first equipped the 6.0L LY6 with a suitable cam to replace the factory VVT set up. The Comp 54-469-11 cam offered a 617/624 lift split, a 231/247 degree duration split and 113 degeee LSA.

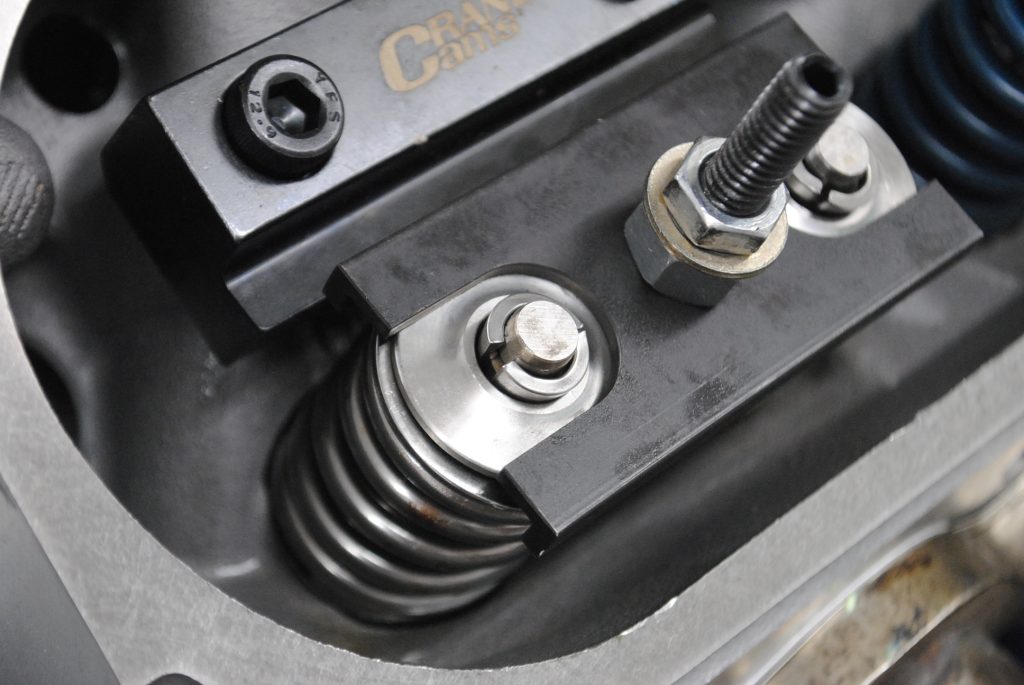

This cam allowed the 6.0L to take better advantage of what the heads had to offer in terms of flow and power potential. The cam lift and rpm potential require a dual valve spring upgrade for all the heads. Brian Tooley Racing supplied the necessary dual spring kit to allow us to safely run the Comp cam and rev the motor easily to 7,000 rpm.

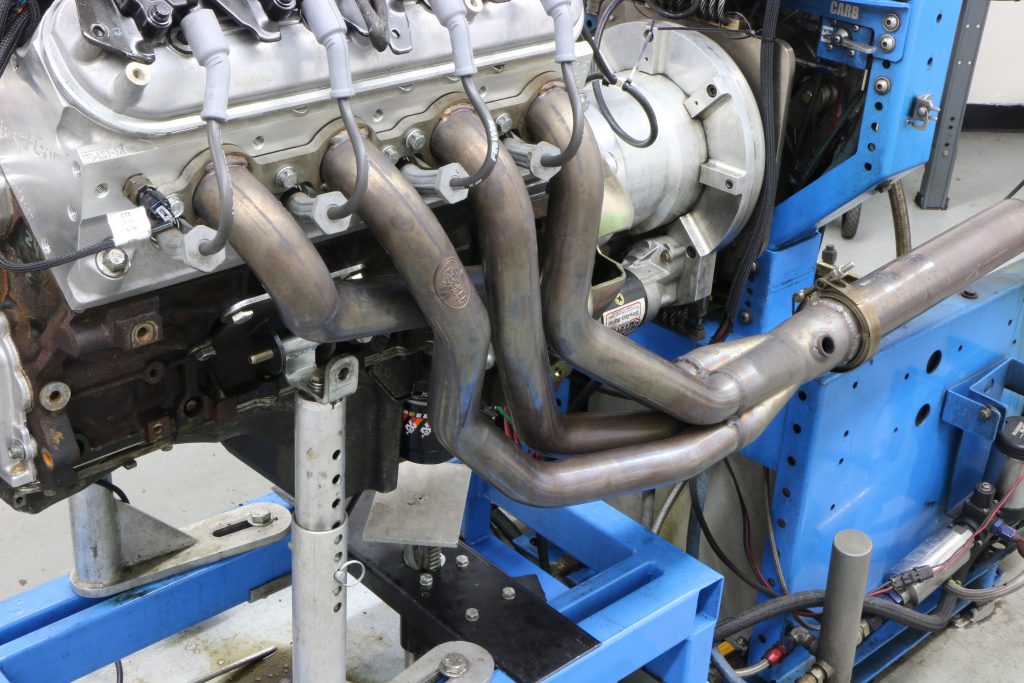

The air/fuel and timing were controlled by a Holley HP management system (controlling 80 pound injectors), while exhaust chores were handled by a set of Hooker 1-7/8 inch (long-tube) headers.

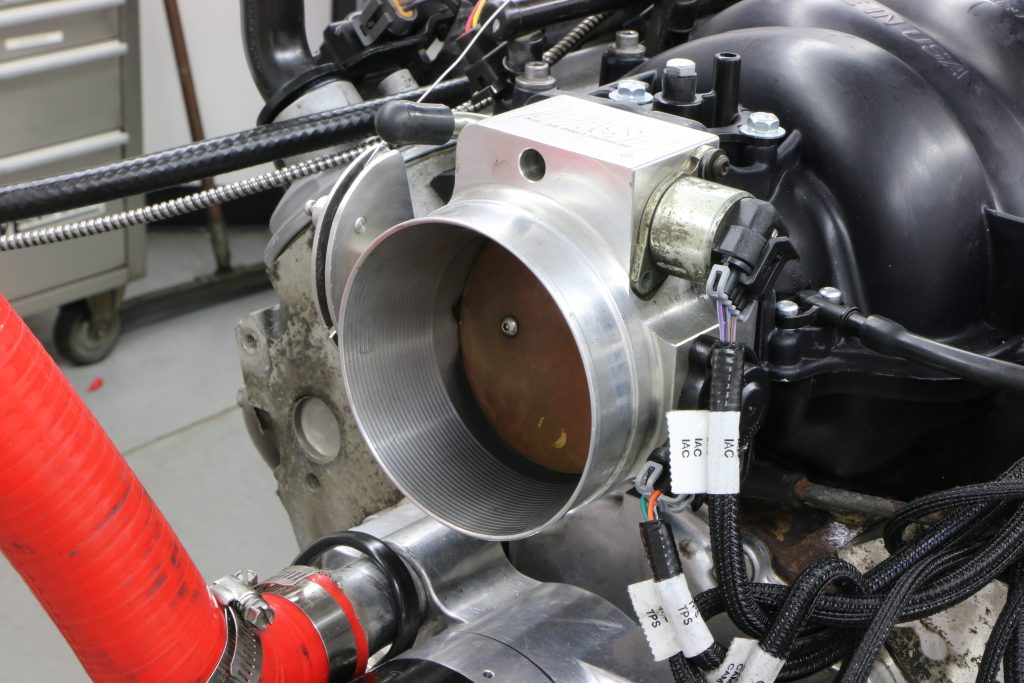

The 6.0L was first equipped with the 706 heads, Dorman intake and 92mm throttle body, which resulted

in 513 hp at 6,300 rpm and 483 lb.-ft. of torque at 4,800 rpm.

Having our baseline established with the smallest of the cylinder heads, it was time to starting swapping.

The LS Cylinder Head Comparison Begins

After installation of the 799 heads (bigger ports & bigger valves produced more flow), the power output of the 6.0L increased to 525 hp at 6,400 rpm and 485 lb.-ft. of torque at 4,700 rpm. The additional flow offered by the 799 head added peak power, but the torque production suffered below 5,000 rpm compared to the (smaller valve, port & chamber) 706 heads.

Next came the rectangle port LY6 heads, which also required the aforementioned offset rockers and LS3 intake. The added flow offered by the LS3 heads (near 315 cfm compared to 250 cfm) pushed peak power up to 544 hp and 492 lb.-ft. of torque. The high-flow rectangular port heads added power above 4,200 rpm, but lost torque below that point to the cathedral port offerings.

The Trick Flow GenX 225 Cylinder Heads came next, and (not surprisingly) offered the most power with peaks of 561 hp and 501 lb.-ft.

Knowing the intake was now holding back the combination, we replaced the Dorman LS2 intake combo with a FAST LSXR intake manifold and 102mm throttle body. This resulted in the highest power output of the test, with peaks of 576 hp at 6,700 rpm and 509 lb.-ft. at 5,300 rpm. Given their flow potential, the TFS 225 heads will support well over 600 hp, so what mods do you think would be necessary to push this 6.0L past the 600 hp mark? Time for those comments!

***

Comments