So…after sitting in your neighborhood shop’s waiting room sipping tepid coffee for an hour, the mechanic just came in, wringing a pair of greasy hands.

Then, they quietly pull up a chair next to you, and explain that your engine will need a top end rebuild.

Once you’re done wincing, you collect your thoughts and ask…

“What Does a Top End Engine Rebuild Mean?”

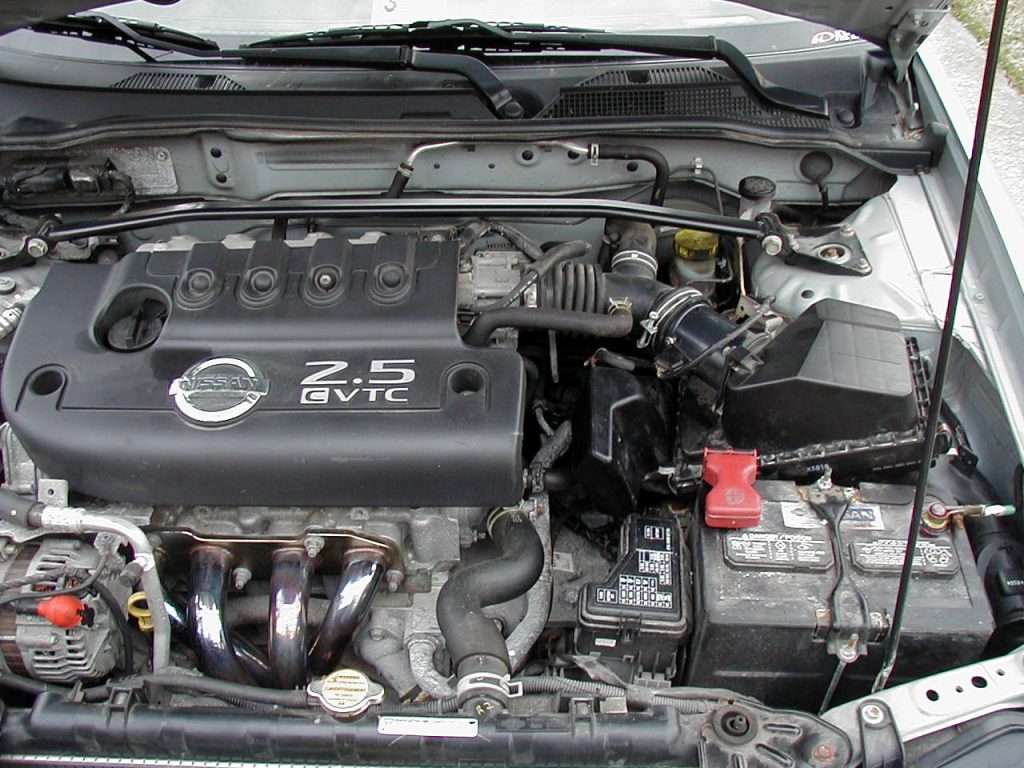

First, some—relatively—good news: It could be worse. From a repair standpoint, a top end rebuild is usually easier on the wallet than a bottom end rebuild. For starters, in a lot of cases, the engine stays in the vehicle.

…Or at least most of it does.

Let’s explain: The engine “top end” refers to things like the cylinder head(s), valvetrain, camshaft(s), timing set, and intake manifold.

- Engine Bottom End – The rotating assembly (pistons, rods, crankshaft), along with the oil pan/pump, main caps, and related bearings, gaskets, and seals.

- Engine Top End – Camshaft, cylinder heads (with valvetrain, plus any requisite pushrods and lifters), intake manifold, timing set (gear/chain), and any related bearings, gaskets, and seals.

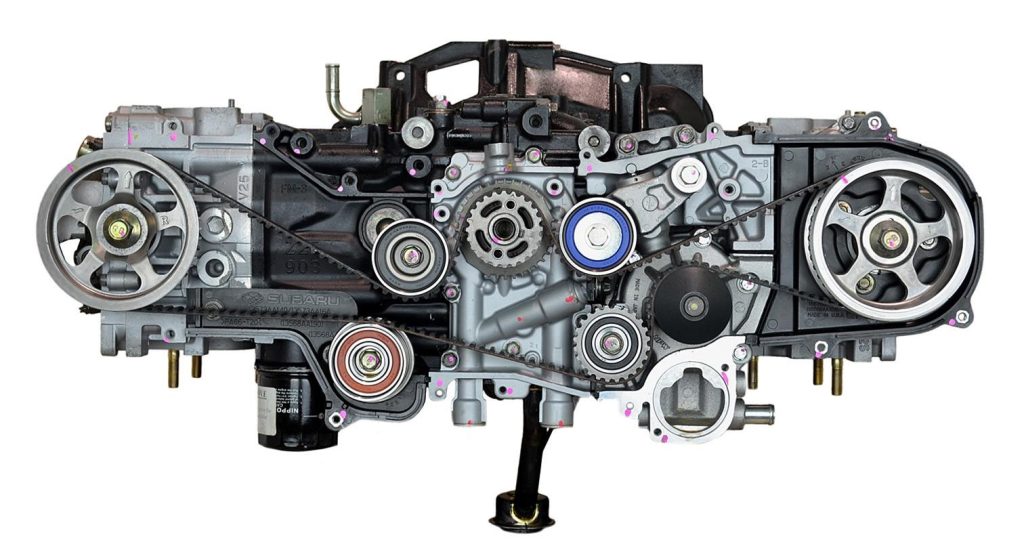

But don’t let the word “top” fool you—depending on your engine design, the cylinder head(s) and related top end parts can be located at an angle and, in some cases, even on the side of the main engine block. It’s called the “top” end because it refers to the apex of the piston stroke, not the physical orientation of the motor.

Understanding the Parts of an Engine Top End

So far, we’ve focused on cylinder heads, but in most cases, the other related top end components are located at or near the top of the engine (aka piston stroke) too.

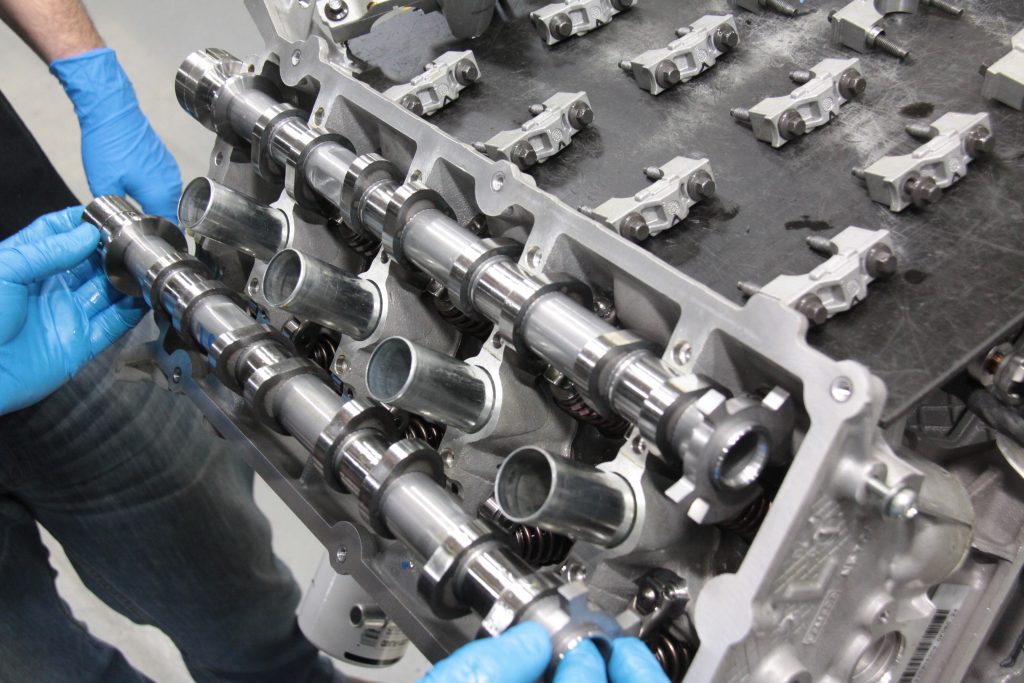

The cylinder head(s) houses the valvetrain, which is what controls the flow of air into and out of the engine (in the form of exhaust). The valves are regulated by the camshaft(s) which, thanks to the timing gear/chain/belt, ensures that the valves open and close at precisely the right time.

But here’s the most important thing to note: Regardless of where they’re physically located in the engine, all these top end parts all connected—sometimes literally. That means, if one top end component got damaged, then you’ve usually got to service (or at least, investigate) the whole darn thing.

In other words, a bad valve might have damaged both the cylinder head and the camshaft. More importantly, to fix a valve, for example, you’ll usually have to remove the cylinder head. So it usually makes since to replace everything once you’re already in there doing most of the work anyway.

The whole “replace everything” approach is particularly important when you consider a high-mileage engine that already has significant valvetrain wear-and-tear. And the job makes even more sense when you’ve got an overhead cam engine—because the cylinder head, valvetrain, and cam(s) are often removed as a single unit.

With that (finally!) said…

What Gets Replaced in an Engine Top End Rebuild?

There’s no single answer to that, as it depends largely on your specific engine. And it also depends if you’re doing a performance upgrade, or simply repairing a stock daily driver.

To begin with, on an ordinary commuter vehicle, your mechanic may send your cylinder head to a machine shop for a repair instead of an outright replacement. The freshly cleaned and machined head would then get fitted with an all-new valvetrain (valves, rockers, etc.).

But during a top end rebuild, pretty much every other moving part gets replaced—and that often includes all the nuts, bolts, and studs used to fasten everything together. As we alluded to above, the “replace everything” mentality is a smart move, because you’re doing the work anyway and this way, it means you’ll have all-new components in place, ready to last for thousands of more miles.

Here’s what’ll go into a typical top end engine rebuild:

- New/Remanufactured Cylinder Head(s)

- New Valvetrain, with Rocker Arms, Valves, Springs & Retainers

- New Pushrods & Lifters (if applicable)

- New Camshaft(s)

- New Timing Chain/Belt/Gearset

- New Gaskets, Seals & O-Rings

- New Assembly Hardware

For a stock repair, you’ll likely be able to re-use your stock intake plenum and tubing. If you’re installing a performance top end engine upgrade kit, then it may include a new intake manifold.

***

All told, a top end rebuild isn’t the end of the world. Thanks to modern engine design and metallurgy, the “bottom end” of an engine is usually pretty stout nowadays, which means—provided there was no damage to the cylinder walls, piston heads, or rotating assembly—a good top end engine rebuild can often outlast the vehicle itself.

Comments