How much is an LS cam swap worth? As always, the answer is…it depends.

While it is not uncommon for cams swaps to be worth 40, 50, or even 60 horsepower on a typical LS application, cam swaps can be worth a lot less or (as shown in these two tests) a whole lot more.

Why such a broad range of power gains you ask? Are there mystical, magical, Merlin-esque cams specs that somehow transcend the laws of physics?

While cam specs do indeed play a major part in the eventual power production, the reality is that the rest of the combination plays at least an equal part. The two tests shown here illustrate impressive power gains offered by two different combinations.

The Cam Swap Test Motor & Upgrades

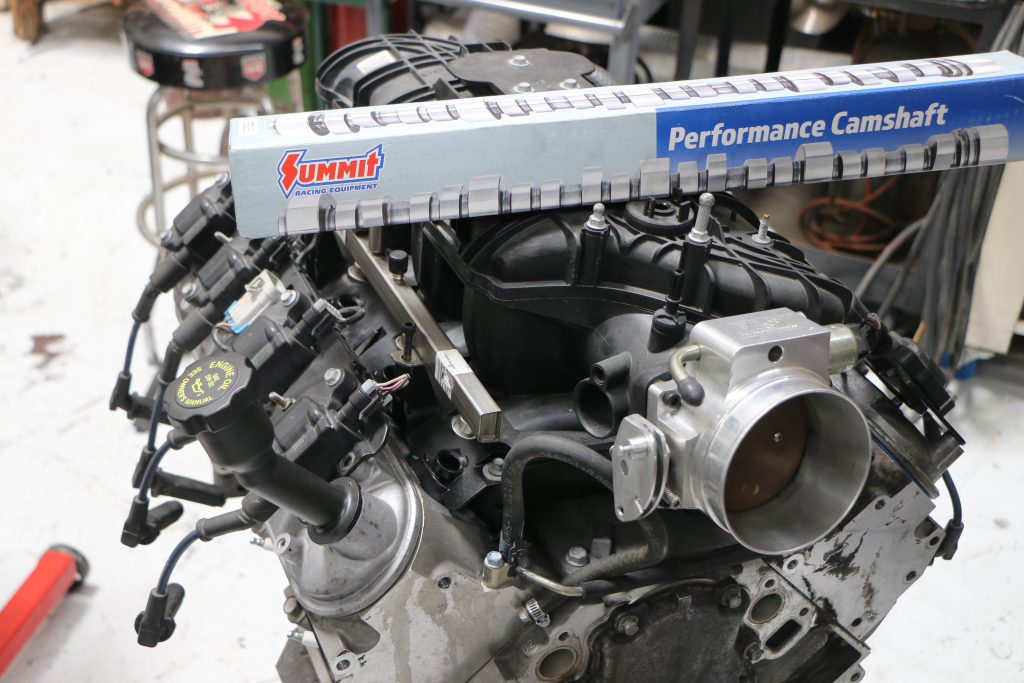

We started with a healthy Summit Racing Stage 4 cam on an otherwise stock 6.2L L92. The L92 was factory equipped with rectangular port heads and a healthy intake, but the stock motor was nowhere near as serious as the larger, more powerful 408 Stroker used in the second test.

Given the needs of the larger motor, it is not surprising that the larger 408 responded even better than the 376 (6.2L) to a cam swap. The combination of displacement, compression, and head/intake flow left the bigger motor just begging for wilder cam timing.

The first test involved the installation of the Summit Racing Pro LS Stage 4 cam in the otherwise stock 6.2L L92. The test motor was on loan from our good friend Jason Trejo over at JTFab.

Eventually this L92 would see Summit Racing Pro LS internal components for boost, but we decided to start on the mild end of the destructive scale, with a simple cam test. After all, even though the L92 offered plenty of displacement and head flow, it, like all LS motors, was in dire need of a cam swap. Even if nitrous and boost happen to follow, every motor deserves to produce decent power before the adders come into play, right?

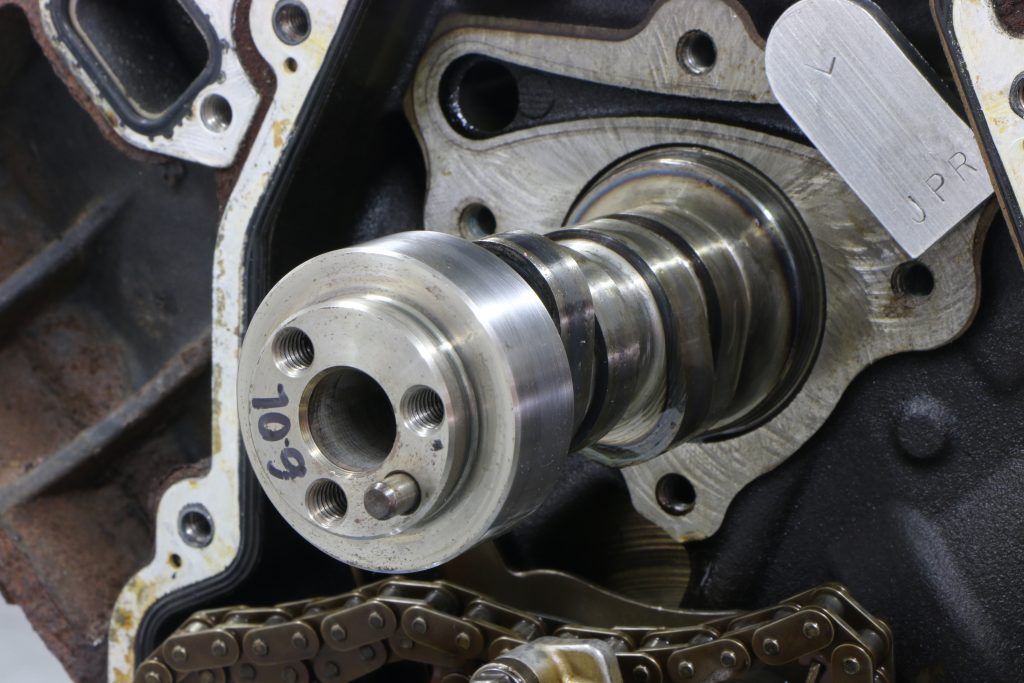

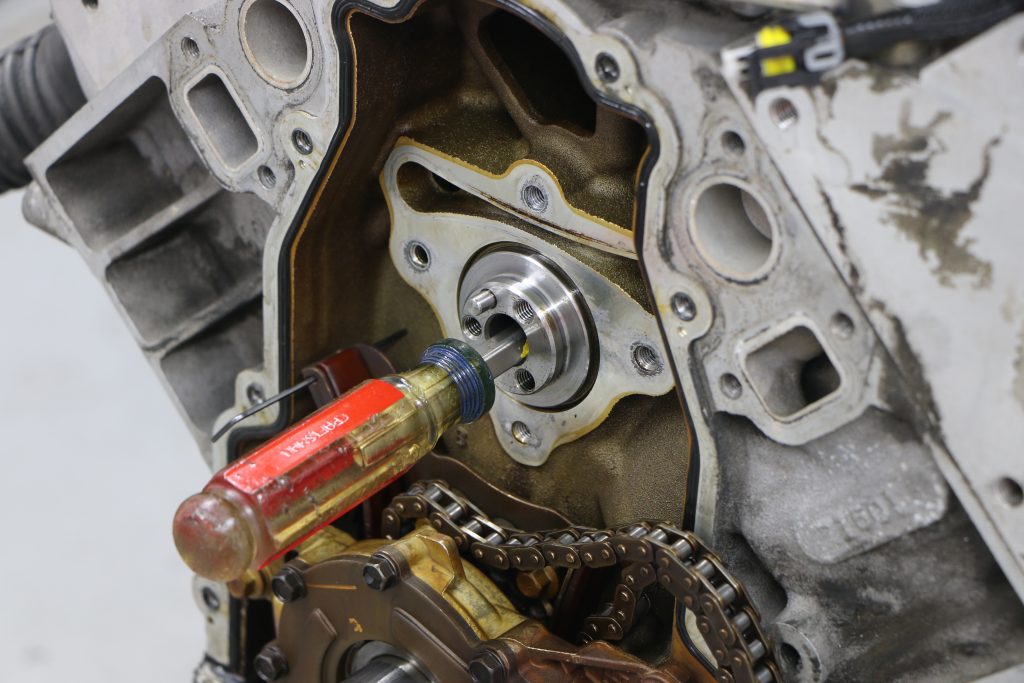

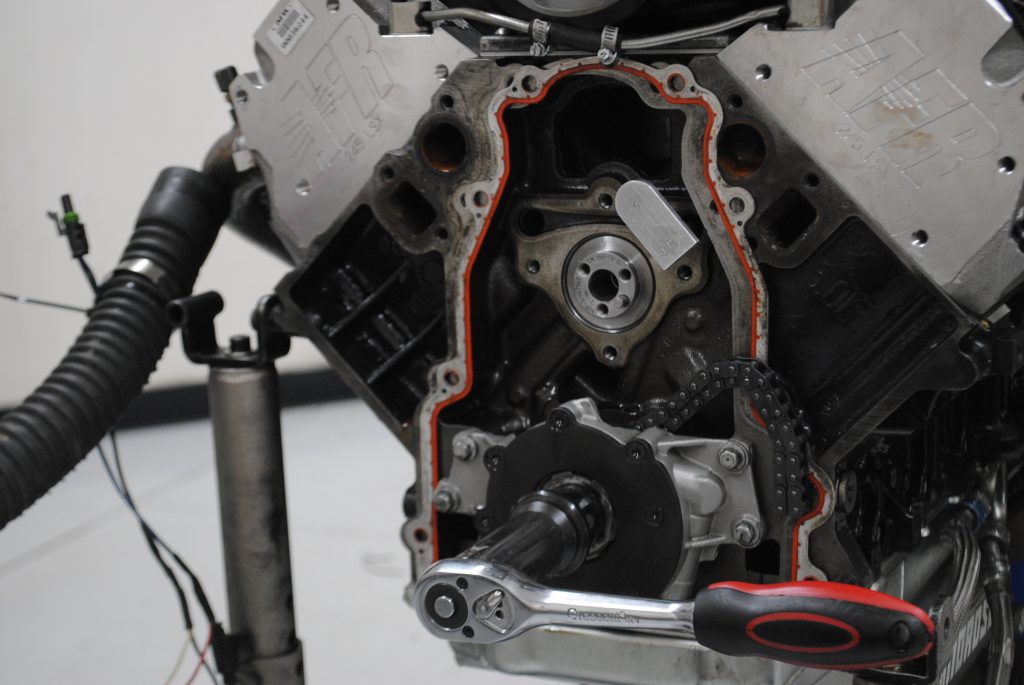

Before testing, the loaner L92 required removal of the VVT and DBW throttle body. The Holley HP management system did not allow us to run the variable cam timing so it was replaced by a fixed LQ4 cam. Likewise, the DBW throttle body was ditched in favor of a manual 92mm Fast throttle body.

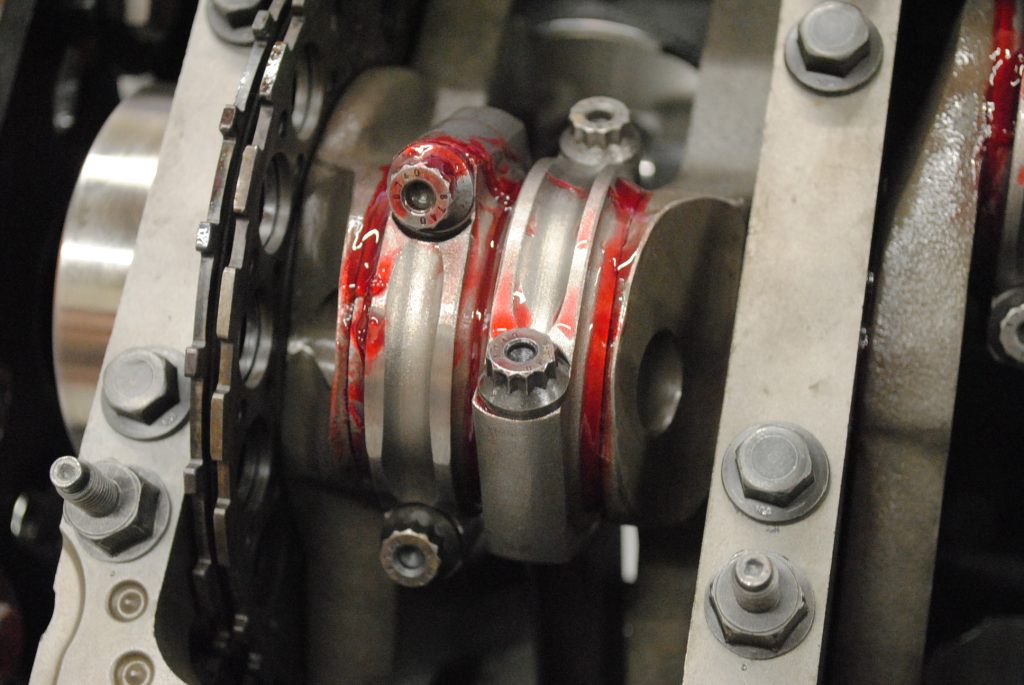

The final two changes prior to testing included replacement of the factory exhaust manifolds with long-tube headers and the installation of a dual valve-spring kit from Brian Tooley Racing—the healthy Stage 4 Pro LS cam certainly required a spring upgrade.

The 6.2L L92 Cam Swap Test

Once we replaced the VVT cam and DBW throttle body, the rest of the test procedure was a breeze. All that was necessary was to dial in the tune on the LQ4 cam, then perform the same procedure after swapping in the Summit Racing Stage 4 cam.

Speaking of the Stage 4 cam, the Summit Racing grind was a healthy customer. The Stage 4 Pro LS cam (SUM-8711) offered a 0.625″/0.605″ lift split, a 234/247 degree duration split, and 113+3.5 degree LSA. Summit Racing offers not one, but two different Stage 4 LS cams. Compared to the slightly more aggressive Stage 4 LS grind (SUM-8709), which offered 0.625″/0.605″ lift split, a 237/246 degree duration split, and 113 degree LSA, the Stage 4 LS3 cam offered slightly more (0.015″) piston-to-valve clearance.

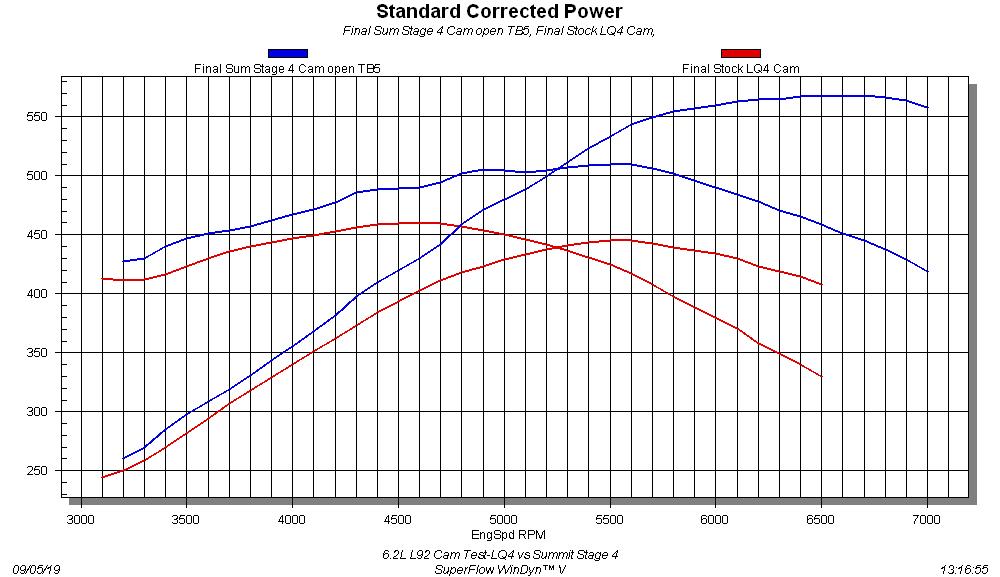

Run with the 1-7/8 inch headers feeding the 3.0 inch exhaust, the LQ4-equipped L92 produced peak numbers of 445 hp at 5,600 rpm and 460 (459.9) lb.-ft. of torque at 4,600 rpm.

With our baseline run, it was time to upgrade the cam. After installation of the Summit Racing Pro LS Stage 4 cam, the peak power numbers jumped to 568 hp at 6,700 rpm and 510 lb.-ft. of torque at 5,500 rpm.

The Summit Racing camshaft improved the power output of the L92 by an impressive 123 hp.

The 408 Stroker LS Cam Swap Test

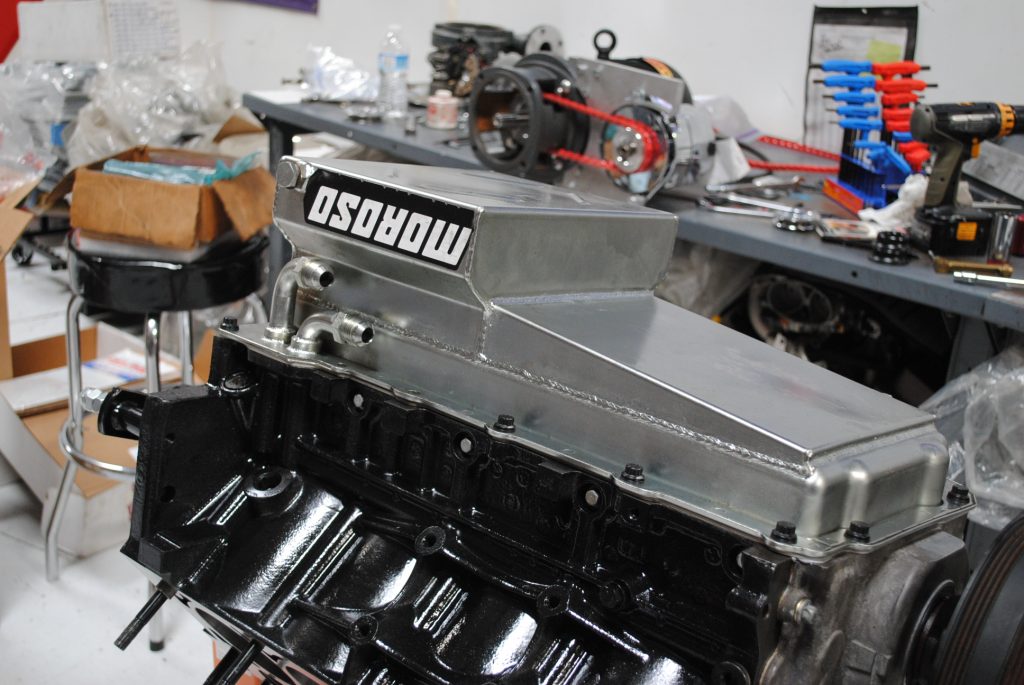

The second test involved a 408 stroker that included a SCAT 4.0 inch forged steel stroker crank combined with (Bullet series) 6.125 rods and forged dish pistons from CP/Carrillo. The bottom end was also augmented with a Moroso oil pan, pick up and windage tray while we started out with the factory LM7 (4.8L/5.3L & Early 6.0L) cam.

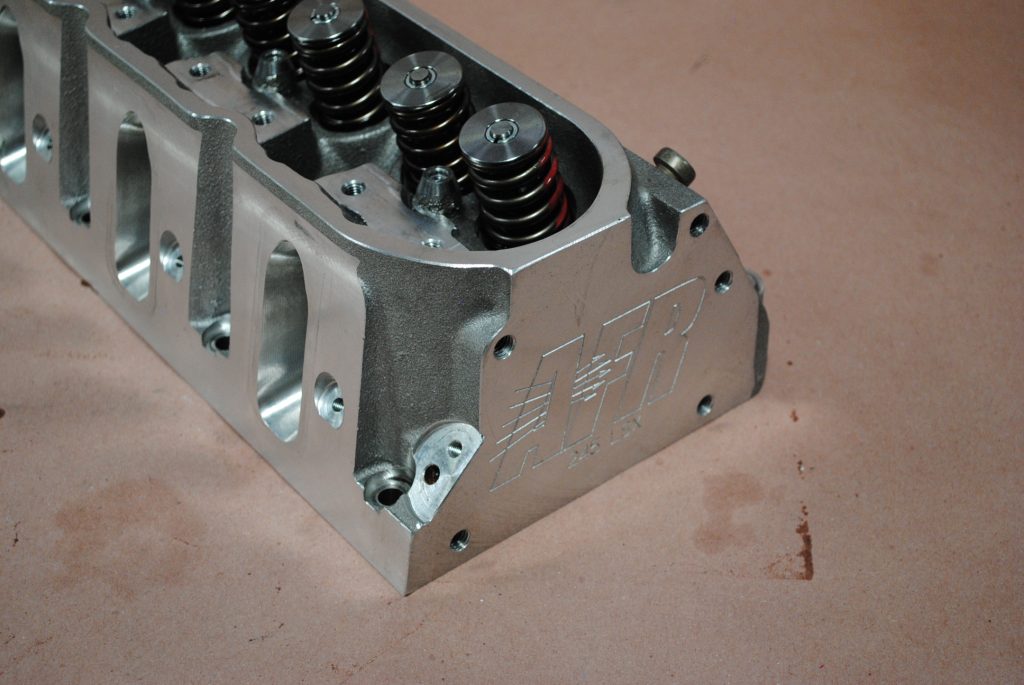

To ensure adequate head flow, we topped the 408 stroker with a set of cathedral port AFR 245 Mongoose cylinder heads. In addition to full CNC intake and exhaust porting, the AFR 245 heads featured a 2.165/1.60 stainless valve package, 5-angle valve job and full CNC chamber work.

The AFR 245 heads were topped off with a FAST LSXR intake and 102mm Big Mouth throttle body.

Stock rockers, 120 pound injectors and HP management system were also employed on the 408. Run first with the stock LM7 cam, the 408 produced 449 hp and 522 lb.-ft. of torque. After installation of a larger Crane cam (0.600″ lift, 240-246 degree duration and 114 degree LSA), the peak power output jumped to 625 hp and 576 lb.-ft. of torque.

The cam swap on the 408 netted an additional 176 horsepower over the stock cam, illustrating that you can look like a hero when the combination is literally begging for wilder cam timing. It bears mentioning that the healthy Summit Racing Stage 4 cam (and others with similar specs) would give equally impressive results on the bigger 408.

Comments