I need your thoughts please. I’m installing KB157-060 (0.60 over) pistons in a 327 I’m building for a friend. The pistons have a slight dome and I’m a bit concerned that I might be getting into detonation problems. This is a street motor with iron 64cc heads with no work to the heads or the chambers. I’ve not decked the block nor removed any material from the piston domes. The camshaft I’ve chose is a 268H Comp High Energy with 218 degrees at 0.050 on both intake and exhaust and 0.454 inch lift.

I’m considering a thicker gasket at 0.041 inch to help reduce the compression slightly.

Do you think I will have piston-to-valve clearance issues?

J.H.

***

There’s quite a bit of ground to cover on your question so let’s dig into the details.

We looked up the piston at SummitRacing.com and then ran some compression ratio calculation estimates using Summit Racing’s online free compression ratio calculator program.

Calculating & Assessing Compression Ratios

The piston-to-deck distance is the one spec you didn’t supply so we had to guess at that one. The KB piston is listed as having a dome but when you subtract the valve reliefs it is very close to a flat top piston where the dome volume cancels out the volume of the valve reliefs.

With a 64cc chamber, a 0.031 inch head gasket, and a 0.005 inch piston below the deck the compression is 10.75:1. That might get the engine close to detonation on 91 octane fuel. The issue in your case is the combination of a slightly domed piston with a not-so-great combustion chamber design.

We can estimate some things to get closer. The stock deck height on a small block Chevy is 9.025 inch. If we take the piston compression height of 1.687, add the rod length of 5.70 inches, and half the stroke (3.25 / 2 = 1.625 inches) all this equals 9.012 inches. This is 0.013 inch short of the stock deck height. In theory this puts the piston roughly 0.010 inch below the deck. With a 0.039 inch gasket this puts the compression at around 10.4:1, which is a good overall combination.

This particular combo of the piston 0.010 inch below deck and a 0.039 inch gasket makes the piston-to-head clearance 0.049 inch which is more than enough. If would be nice to be closer but then as the piston deck height position moves up, the compression also increases. That’s why I said the 10.4:1 compression would be a good place to start. If you run a 0.041 inch gasket, it doesn’t change the compression enough for concern.

Timing, Rings & Other Factors to Consider

These older small block chambers tend to want more timing to compensate for their poor design. The problem is that they also tend to rattle more easily than newer chambers. That’s why the new LS engines can make more power with less timing. In many cases, LS engines only run 22 to 24 degrees of total timing where the older SBCs need 34 to 36 degrees of timing.

It’s also a good idea here to emphasize that the top piston ring end gaps on these KB pistons must be set to a wider clearance. KB moves their top ring up in the piston and if you don’t set the proper end gap the ring ends will butt and the piston will stick in the bore. Their clearance factor is 0.0065 inch per inch of bore. This puts the top ring gap at 0.0265 inch and slightly more for the second ring. The math looks like this: 4.010 x 0.0065 = 0.0263 inch.

This is important to mention because we’ve seen a situation where the engine builder set the top ring clearance too tight on KB pistons. The engine ran for about two minutes then stuck the piston in the bore and broke the top half off the piston off just above the bottom ring land! While hypereutectic pistons are stronger than cast, they are still a cast piston and this is what happens. So consider this as a word to the wise when working with KB pistons.

A Final Note on Piston-to-Valve Clearance

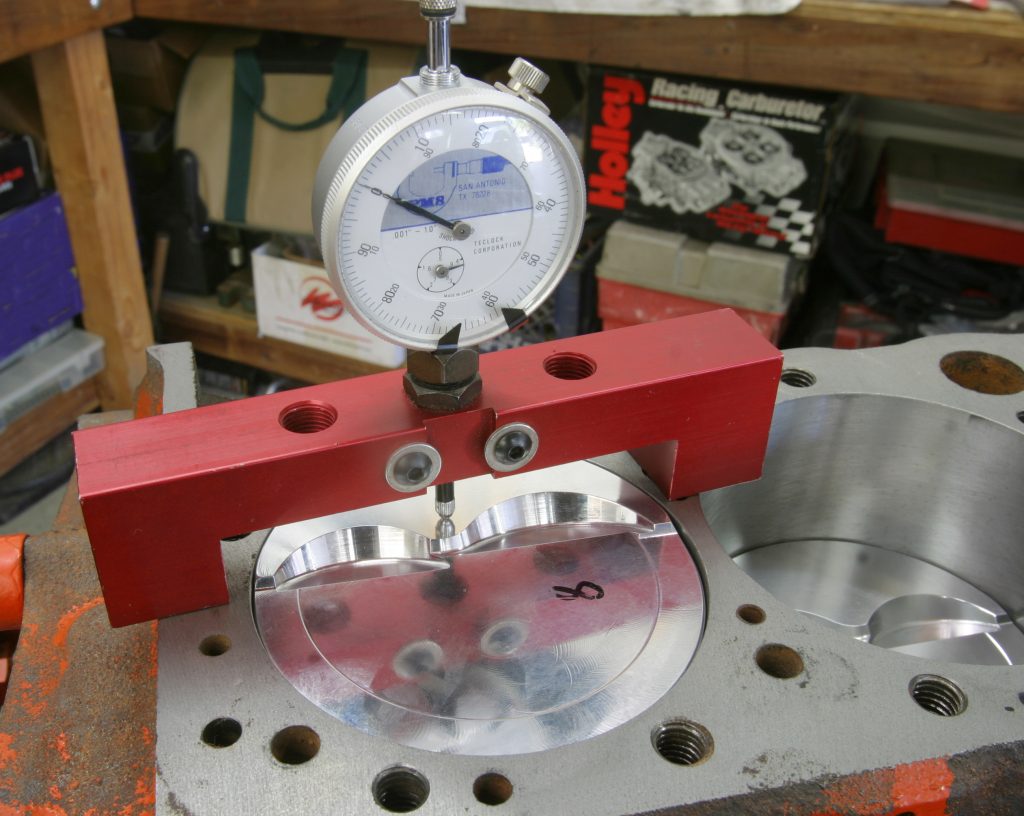

As far as your piston-to-valve question, I don’t think you will be in any danger but the best way to know is to measure. The simple plan is to mock up the heads and cam in the engine with some modeling clay on the piston valve reliefs. Use a solid flat tappet lifter and set the rockers with zero lash and then roll the engine through several revolutions. Then remove the head and cut the clay so you can measure the thickness remaining. Minimal clearance is 0.100 inch but it’s likely you will have much more.

Hope this helps.

Comments