I have this problem with a small block Chevy 355ci that my brother and I just assembled. The engine in the car runs great. But a friend was following me on the freeway the other day and told me later that every time I shifted that a small puff of oil smoke comes out the exhaust. Plus, when I slow down, the oil smoke is there. I can’t see it but he told me that it’s certainly there.

At first we thought it might be bad valve guide seals but the heads are new so I’m guessing this should not be the problem. So now we’re not really sure where this oil is coming from. We thought you might have some ideas. Thanks,

D.T.

This seems to be a more common problem in the last 10 years. This may have something to do with the aging of the small block Chevy or perhaps just the proliferation of this engine. We actually ran into this issue many years ago and we too thought at first that it was valve guide seals. Our engine was not new but we had recently installed a new set of heads and a different intake manifold.

The problem is the relationship between the intake manifold and the heads. With unequal deck heights, or perhaps poor machining, the angle of the intake manifold is not the same as the angle formed by the heads when bolted to the block. What happens is that the gap at the top of the intake ports is tighter than it is at the bottom of the ports. This means that the intake gasket is not squeezed as tightly at the bottom as it is at the top of the port.

This wider gap at the bottom of the port creates a reduced clamp load situation where crankcase pressure inside the lifter valley combines with the vacuum in the intake ports to push oil from the lifter valley past the intake gasket and into the intake ports. This situation is aggravated the most during engine deceleration when intake manifold vacuum is very high. Frankly, oil is being pulled into the ports anytime the engine is running. But it is most noticeable during the high vacuum situations.

In the past, we heard that engine builders often expressed a dislike for a certain intake gasket when the real reason for their dissatisfaction was not the gasket but more likely the fact that intake manifold was not seated properly on the heads.

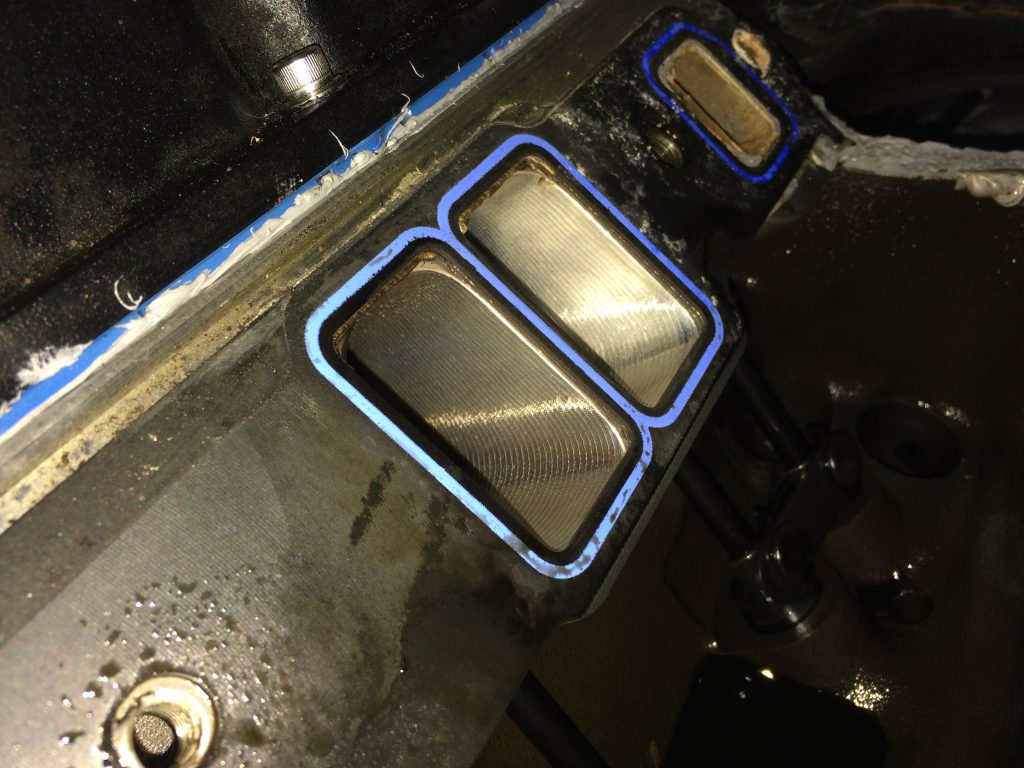

The problem is how to determine if this is where the problem exists. We ran across a simple little tool sold by Hughes Engines in Washington, Illinois. He offers a small kit of several lengths of wax string roughly six inches in length. First you remove the intake manifold and the gaskets and then place one length of string on each of the four corners of the cylinder heads. Then carefully drop the intake manifold down onto the heads and install and tighten all the intake bolts.

Next, remove the bolts and the intake and inspect the wax string. If your manifold is not square to the heads, the upper portion of the string will be squeezed wider than the bottom. This indicates that the manifold is not properly aligned. This often is the result when either the heads or the block has been machined to straighten the deck.

If the gasket is not quite squeezed as tightly at the bottom, you will have to take the intake to a machine shop and ask them to angle machine the gasket surface to remove roughly 0.010-inch or so from the top of the sealing surface of the ports while only removing 0.001-inch or so at the bottom. This will orient the gasket to be flush with the cylinder heads and this should fix your problem.

You can try a thicker intake gasket, but if the surfaces of the intake manifold and the head are not aligned, a thicker gasket may not solve the problem. The best bet is to have the intake machined to improve the surface clamp load on the gasket and this will eliminated oil entering the intake port.

Bad pcv makes the same thing …