I don’t think anyone reading this article likes doing a grease job on a car. It’s almost always messy, and you seem to need three hands to operate the grease gun and while holding the hose on the head of the grease (aka zerk) fitting.

Most late model cars don’t have zerk fittings. On something like a typical first gen Camaro, you’ve got them on the upper and lower ball joints, tie rods, pitman arm, and if equipped with a manual, the clutch z-bar. Some cars have driveshaft greaseable universal joints. Heck, my tractor has 22 different zerks, not including the three-point hitch attachments.

Just like motor oil and speed parts, you won’t get 100% agreement on anything when it comes to tools for grease jobs. Summit Racing’s website is filled with grease job solutions—some traditional and some that you might not be familiar with. Let’s take a look at a few.

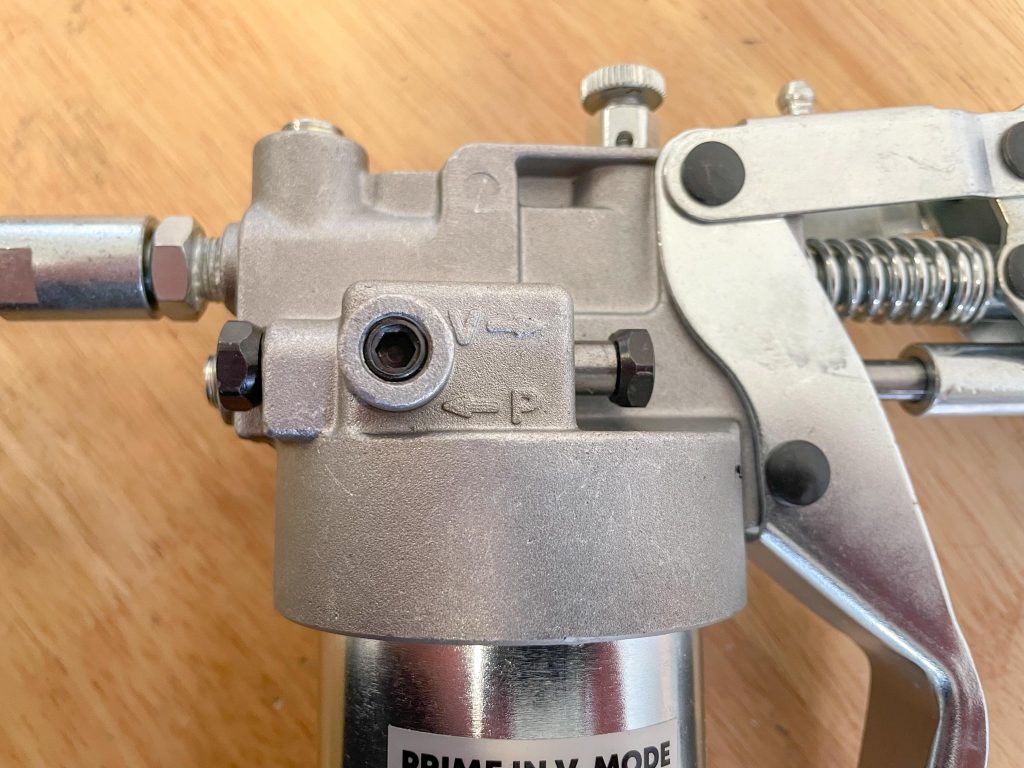

Pistol grip grease guns are great because (at least in theory) you only need one hand to operate one. The LockNLube Professional Series gun is a good example. It allows you to switch between high volume and low pressure by pressing a button on the head of the gun. High volume allows you to grease a zerk fitting quicker, while high pressure can help to clear out a plugged or jammed zerk. This can prove important if it’s cold outside. In high volume mode, the Pro Series gun delivers one ounce of grease for ever every 22 strokes at approximately 2,000 PSI. In the high pressure mode, the gun delivers one ounce of grease for every 70 strokes at approximately 10,000 PSI.

The head of the gun incorporates an air release valve for priming. You can also change the hose location from the front of the gun to the top by removing an Allen plug and swapping the hose.

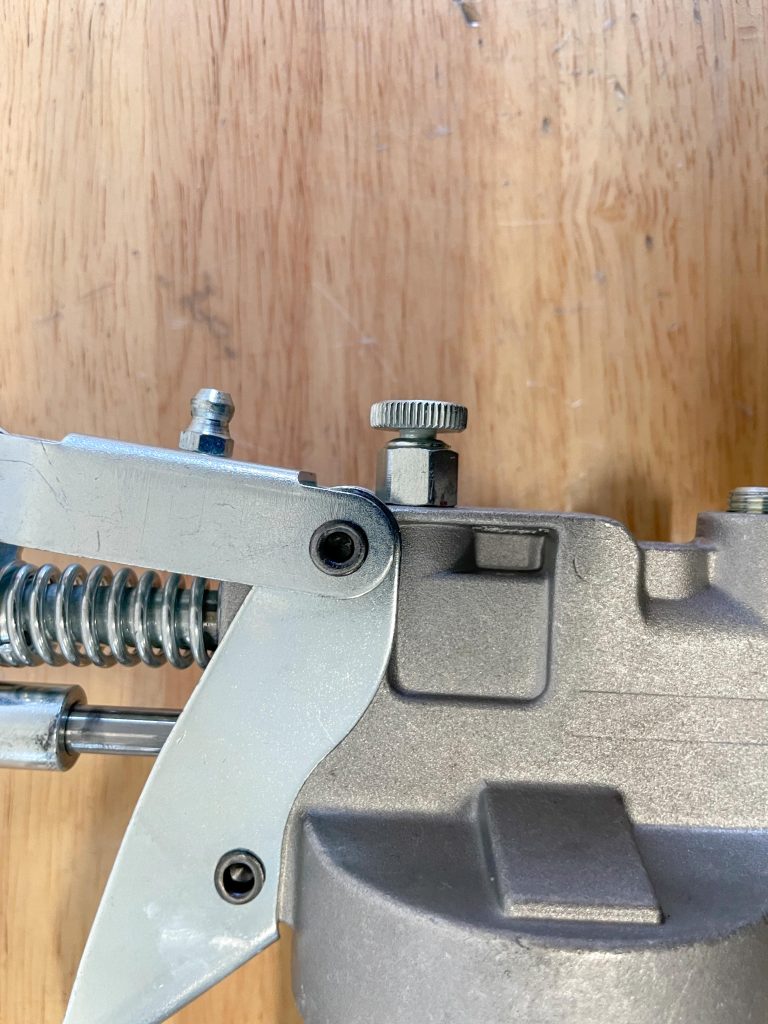

If you have decent size air compressor, another great option air-powered grease gun like this one made by OTC. It offers continuous flow—as long as you keep the trigger down, the gun will keep pumping grease. It’s so effortless you have to be careful not to over-grease.

Loading the air powered gun is the same as any other grease gun. Once its’ loaded, you release the plunger rod from the notch so that it moves forward. This creates pressure on the grease and the air trapped inside the gun’s barrel. As the plunger moves back inside the barrel, the remaining air inside is expelled through the pair of vents on the valve body.

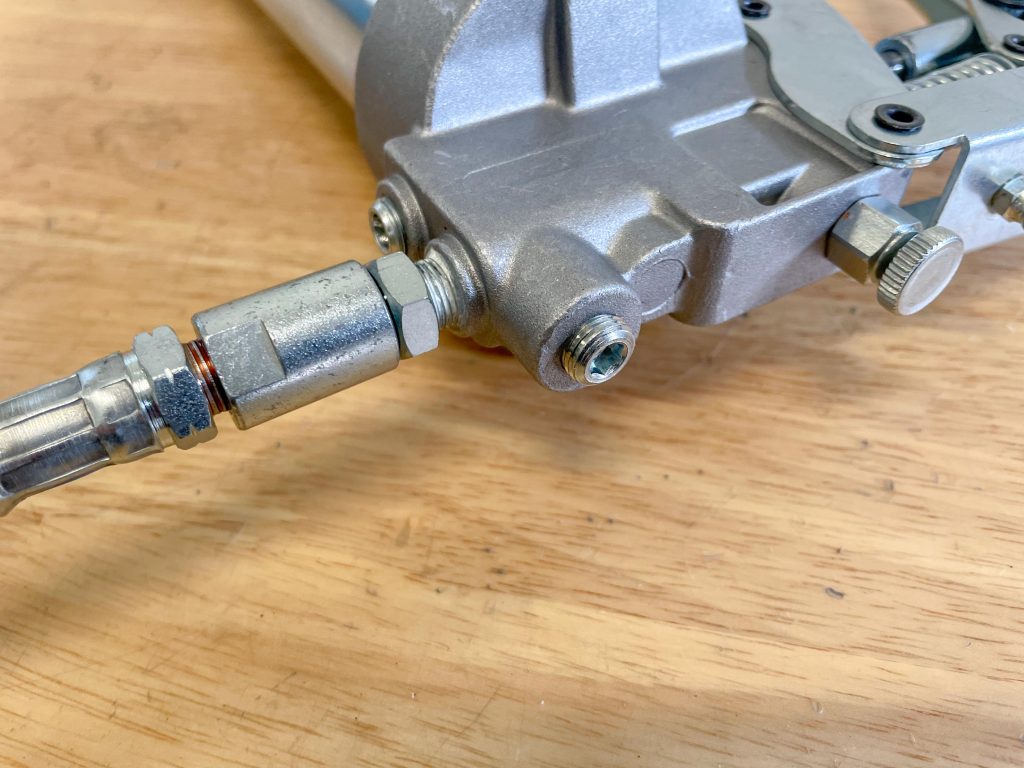

Despite your best efforts, sometimes you end up with more grease outside than inside the zerk fitting thanks to a leaky coupler. Summit Racing sells a LockNLube coupler that can put a stop to that. The coupler is engineered with four hardened steel jaws. You open the jaws by holding down a lever on the coupler. When the coupler is engaged on the zerk fitting and you release the lever, the jaws lock onto the fitting so you’re free to use both hands on the grease gun. The LockNLube coupler can handle up to 10,000 pounds of pressure and fits any grease gun with a standard 1/8-inch NPT hose connection. It is included with the company’s grease guns.

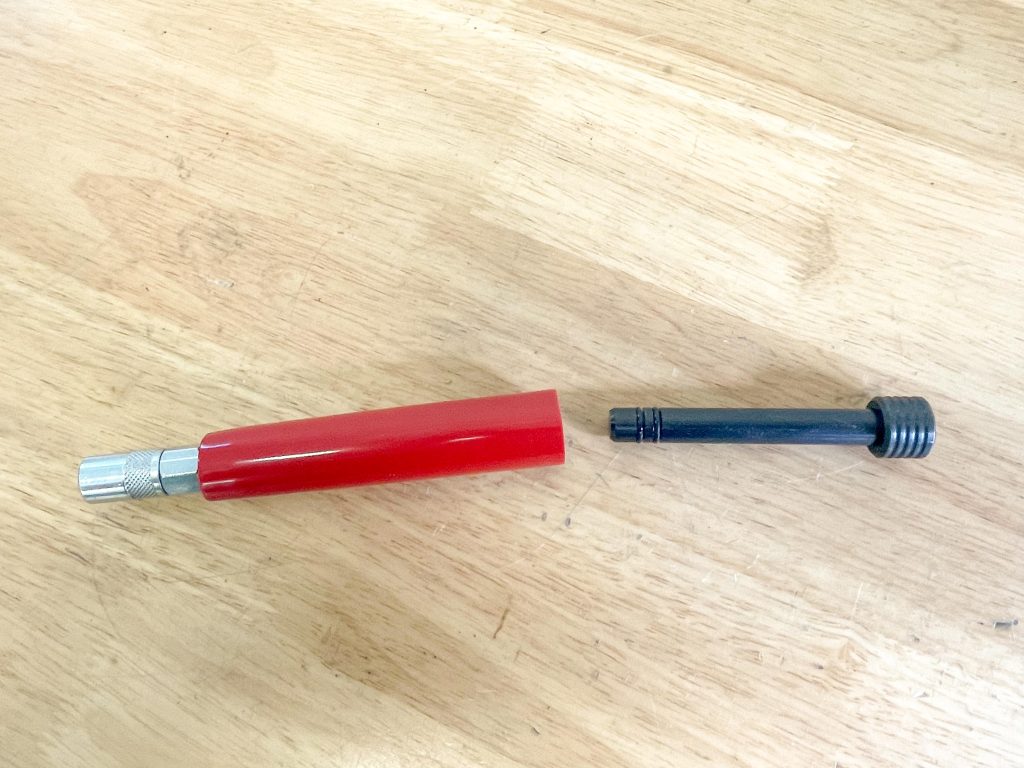

One more interesting grease gun accessory is the LockNLube Grease Buster. This simple little device is designed to open up clogged zerks. Here’s how it works:

• Remove the piston from the end of the handle and fill the tool with solvent (penetrating oil, diesel fuel, WD 40, etc.)

• Reinsert the piston and install the coupler over the zerk

• Tighten the coupler and tap the end of the piston several times with a hammer

You don’t have to give the Grease Buster a big wallop—let the hydraulic pressure and vibration clear the clog. If the clog is stubborn, simply leave the Grease Buster attached to the zerk fitting. Over time, the pressurized solvent will work through the clog.

As you can see, Summit Racing has a number of options when it comes to taking the agony out of grease jobs. Check out the accompanying photos to learn more.

Comments