I recently bought a pretty stout 355ci small block Chevy to put it in my ’70 Nova. It didn’t have a distributor so I bought an MSD Street Pro Billet distributor. At first the engine ran pretty good but when we took the car to the strip, it seemed like it didn’t pull as hard. At first we thought it might be our fuel delivery system but fuel pressure was good. Next we checked the timing curve setting the initial timing at 15 degrees.

Then we checked the total timing looking for advance when I noticed that we had to spin the engine up past 3,000 rpm to get the timing to start to advance. My guess is the springs are too stiff but even then we don’t get much advance out of it. Can you help with this?

G.T

***

This is a common issue with MSD distributors. They are all shipped with the most conservative (heaviest) advance springs along with the black advance stop bushing. Let’s look at the bushing first and then we’ll address the advance springs.

Mechanical Advance Bushing Stops

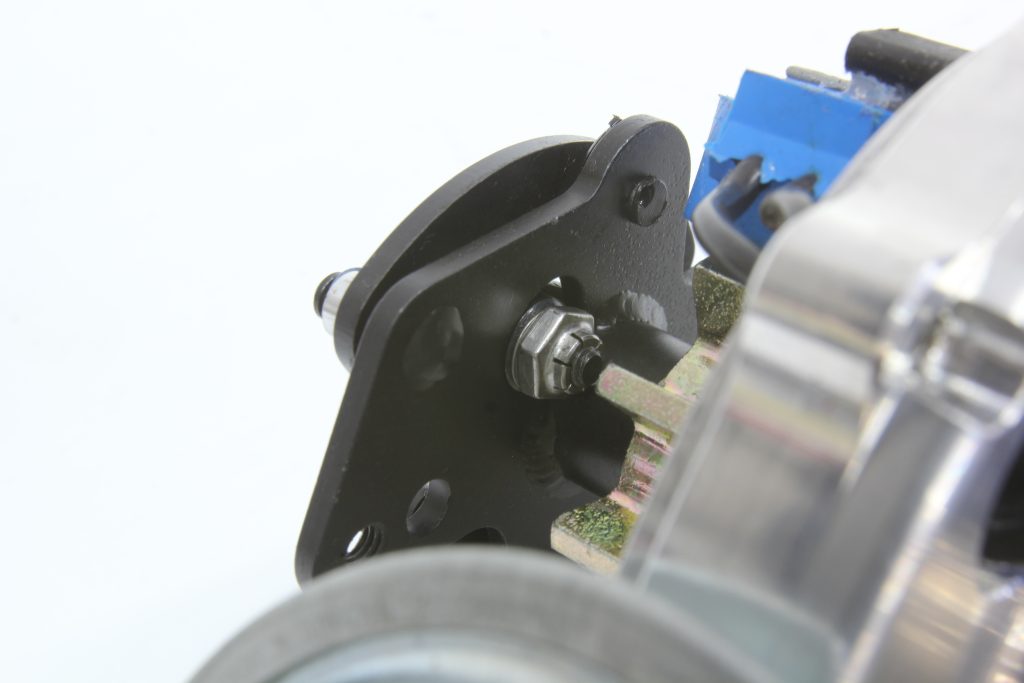

MSD uses a long slot in the plate for the mechanical advance with a small pin that travels within this slot. MSD then uses different bushing sizes (delineated by color) to establish the amount of mechanical advance allowed by the distributor in crankshaft degrees. If you check the chart below, you can see that the black bushing that comes with the distributor only allows 18 degrees of mechanical advance.

MSD Advance Stop Bushing Advance (Degrees) & Color Codes

| Bushing Color | Mechanical Advance Allowed (Crank Degrees) |

|---|---|

| Black | 18 |

| Blue | 21 |

| Silver | 25 |

| Red | 28 |

For a street engine using 15 degrees of initial timing, adding 15 initial to this 18 degree limit on the mechanical advance, will only produce 33 degrees of total ignition timing at maximum advance. That might be fine for some engines but generally a small block Chevy with good heads and compression will want 34 to 36 degrees of total timing to make best power. If you retain the black bushing then the engine will need an initial timing of 16 degrees to create 34 degrees of total timing and 18 degrees initial to net 36 degrees.

If your engine is running a big cam, then 15 to 18 degrees initial will probably work.

With a milder cammed engine you may only want to run 10 to 12 degrees of initial timing at idle. Then you will want to change the bushing in the distributor to a smaller version like the silver bushing that allows 25 degrees of mechanical advance. If you put the initial at 10 degrees, this will create 35 degrees total advance which should work very well.

Of course, each engine is different so experimenting with different advance bushings and initial timing will produce the desired results. You want the least amount of initial timing to create the highest manifold vacuum at your desired engine idle rpm.

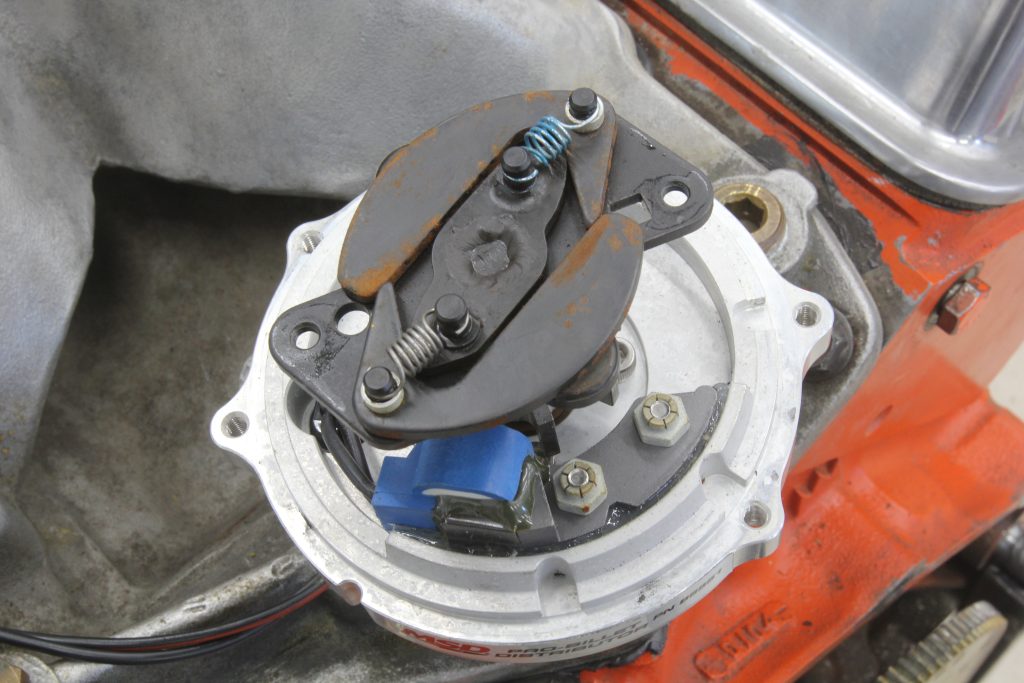

Swapping Advance Springs

Now let’s look at the advance springs. The heavy silver springs are what all MSD distributors are equipped with from the factory. New distributors also come with a collection of lighter advance springs that you can mix and match to create the desired quickness of the advance curve. MSD publishes a set of six different curves you can find on their website that do a good job of revealing the shape of the curve.

To simplify this, the two lightest springs are the light blue or light silver springs that allow the advance to come in the quickest—all in by 2,000 to 2,500 while the two heaviest springs barely start advancing at 2,000 rpm and are not fully advanced until 4,500 to 5,000 rpm.

Generally you want to have the mechanical advance all in by 2,600 to 3,000 rpm.

We’ll skip the whole issue of vacuum advance as we’ve covered this in previous tech columns—though I’ll share some good reading material below.

If you purchased a used distributor, you will probably need an advance curve kit which is available through Summit Racing. This will give you all the springs and bushings to allow you to set your curve up exactly as you want.

Have fun!

Nice info, thanks