After 60 years of continuous production, there is plenty of myth, mystery, and misinformation about the Ford Mustang. Take the Mustang’s original 1964 production launch. While we know a lot about it, there are unanswered questions. Ford deleted production records at the end of each model year until record keeping became federally mandated in 1967 for all automakers. That means official documentation the pre-production and full production launch in 1964.

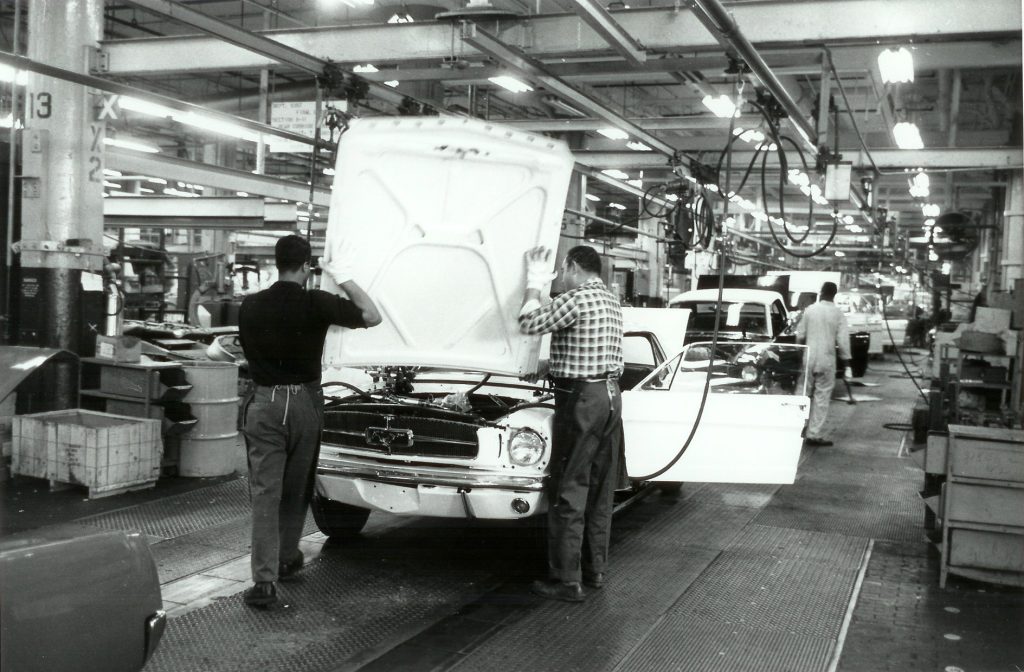

For example Ford historians, including myself, have combed Ford’s photo archives extensively for at least four decades and have found just a few images from the gen-one Mustang’s production launch. Images of Job 1 at Ford’s Dearborn Assembly Plant have never been found.

Here’s what we’ve learned about the Mustang’s beginnings from Ford insiders who saw it firsthand in 1964.

Prototypes

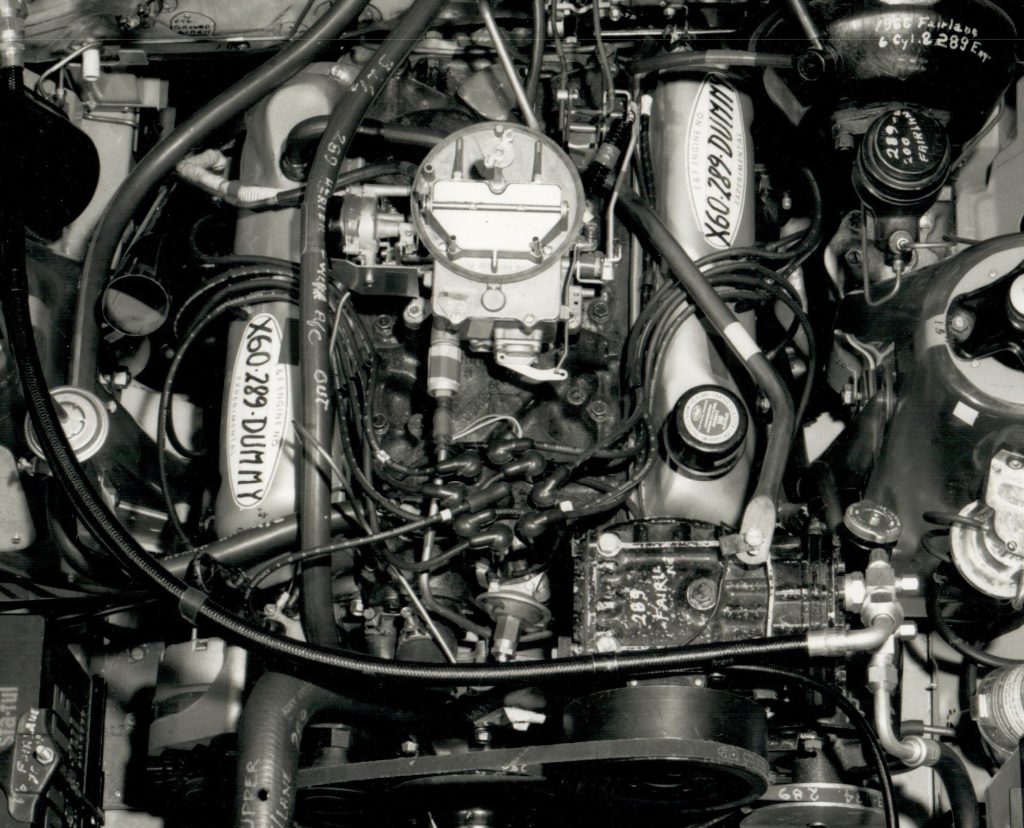

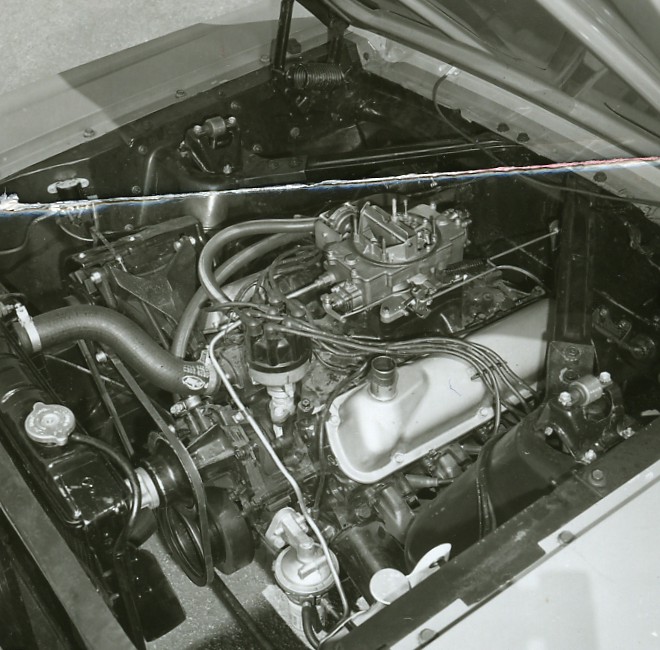

Virtually every part on a Mustang began as a prototype. Prototyping serves to provide specifications for a real working unit rather than a theoretical drawing on paper. A prototype could also be a hand-built body, parts of a body, or a complete drivable example.

As a rule, prototypes were destroyed to avoid winding up in private hands—or worse, in the competition’s hands. However, Detroit garage sales are notorious for having prototype automobile parts that went quietly went out the back door.

Mustang prototype units did receive identification numbers. We don’t know how they were numbered or if any Mustang prototypes survive today. If someone claims to own a Mustang prototype, chances they’re mistaken and actually own a pre-production car. I can tell you putting such a vehicle in private hands would be a huge liability for the manufacturer. As a rule, it just doesn’t happen.

Pilot Units

Pilot Mustangs were built in Ford’s Pilot Plant in Allen Park, just south of Dearborn at I-94 and Southfield. Known as Vehicle Operations today, the plant is where vehicle assembly is tested out on a small scale (typically with 10-20 units) to make sure everything goes together smoothly and functions as designed.

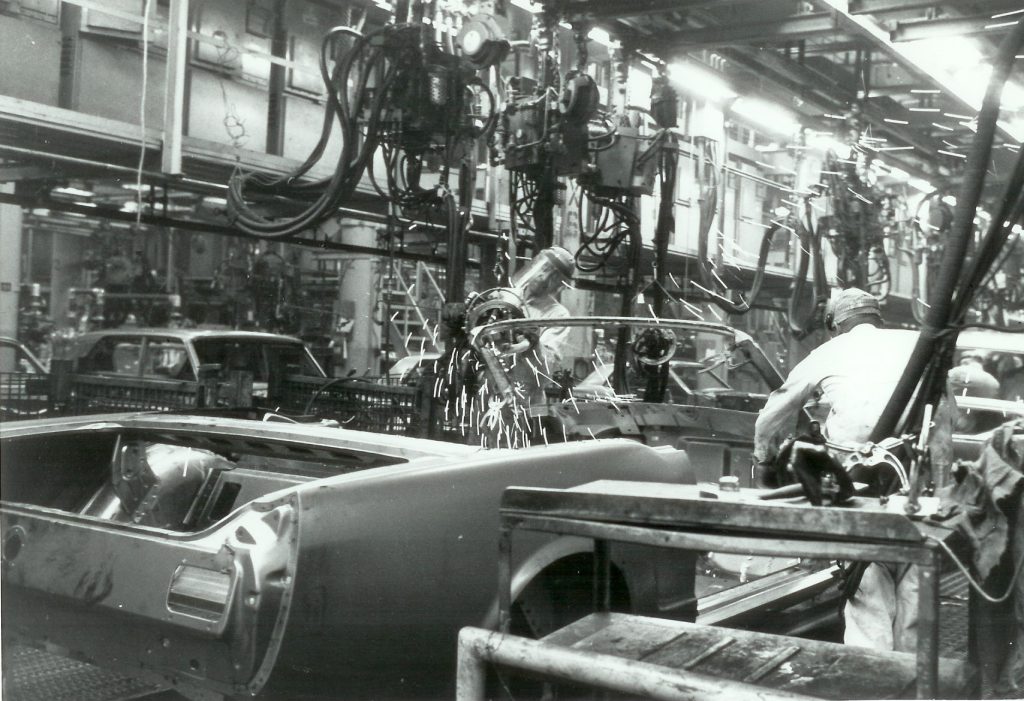

Pilot units were often put together with crude methods, including stick welding and cutting torches, to get parts to fit properly. This work led to stamping dies being revised to produce better parts.

Pilot Mustangs were built with both pilot and prototype parts. I’ve seen both on early production units as well. You can even find Falcon parts on pilot Mustangs as well as parts that were never mass produced.

The first two scheduled pilot units—5S??K100001 and 5S08K100002–were K-code 289 High Performance Mustangs, which theoretically make them the first ones built. Both were documented as scrapped, but Ford records offer two stories on 5S08K100002. One is that the car was shipped to Holman & Moody. The other version says it was built as the Mustang III concept car.

Pilot units were typically destroyed after assembly. Many were crash test vehicles, and some were donated to vo-tech schools and museums. Several pilot units were sent to Dearborn Steel Tubing (DST) to be turned into concept cars. One of those cars, number 5S07F100009, wound up in private hands.

Pre-Production Units

Once pilot production was complete, a limited run of cars were built as pre-production units at the Dearborn Assembly Plant. This continued the process of working the bugs out and determining what needed parts or assembly methods needed to be revised or entirely redone.

According to the February 28, 1964, edition of Ford’s The Rouge News, some 150 pre-production Mustangs had been built at the Dearborn Assembly Plant. I’ve been told by Ford insiders who were there at the time that approximately 150 to 200 total pre-production units were built. The exact number isn’t known because some units were ordered and not built, leaving unbuilt VINs (Vehicle Identification Numbers).

Based on pre-production Mustangs we have seen, each had a sequence number at the top of the radiator core support. This number indicates exactly where each unit was positioned on the Dearborn line. The sequence number was hand-written with an acid-etch pencil or a paint pen that left a permanent mark in the steel. Unless the number was sanded off during a restoration or the radiator core support was replaced, it should still be on the car.

The late United Airlines captain and Ford historian, Bob Fria, did extensive research into pilot and pre-production Mustangs. He also solved the big “05C” date code question. This code was assigned to all pre-production Mustang units built before mass production began on March 9, 1964. The 05C code was the ‘flag’, or scheduled build date, but not always the actual build date. All 05C date-coded Mustangs were built between January and March 1964.

Narrowing down the actual build date of an 05C pre-production car means finding the dates and date codes of the original parts and components installed. If you have access to an unmolested pre-production car, you can examine sheetmetal stamping dates, part casting dates, and dates printed on different components to learn when the Mustang was assembled.

The highest known VIN number for a pre-production Mustang is 5F08F100173, now owned by Frank Middleweek. It had an export DSO of 91, indicating the car was shipped to England. Pre-production Mustang 5F07F100192 was allegedly a press vehicle delivered to Petersen Publishing Company, which produced Hot Rod and Motor Trend magazines among others. However, there is also documentation showing 5F07F110192 as delivered to Petersen, so it’s unclear today which car they actually got.

Another interesting tidbit—pre-production cars with VIN numbers 5F07F100023, 5F07F100024 and 5F07F100031 were ordered and built for the independent rear suspension development program. By the time the program was complete, Ford was already working on the Mustang for 1967. That would have meant running the IRS program all over again. The cars were scrapped.

Mass Production

It appears Mustang mass production began with VIN 5FXXX200200 or 5FXXX100201 on Monday, March 9, 1964. The earliest known mass production unit with an 09C date code for March 9 is 5F07U100211, a base hardtop now in the Mustang Owners Museum in Charlotte, North Carolina. It is currently unknown which 09C car was Job 1. Without legitimate Ford documentation, Job 1 claims cannot be substantiated.

The six-digit Consecutive Unit Number is a job or invoice number and did not indicate where a Mustang was positioned on the assembly line. Consecutive unit numbers were specific to each assembly plant for each model year.

Here’s an example. Ford vehicle serializing began with 100001 (Mercury was 500001 and Lincoln 600001). If your car’s VIN is 172321, you have the 72,321 unit ordered for that model year at that plant only. Because the 1965 Mustang and 1964 Fairlane were built at Dearborn at the same time before June 15, 1964, there is some confusion about how they were numbered. Because Fairlanes were 1964 models, their VINs began with 4FXXX100001. Mustangs were 1965 model year units beginning with 5F08F100001.

The Rotation Number or Line Sequence Number do confirm where vehicles were positioned on the line. These numbers made it easier for plant personnel to locate cars on the line.

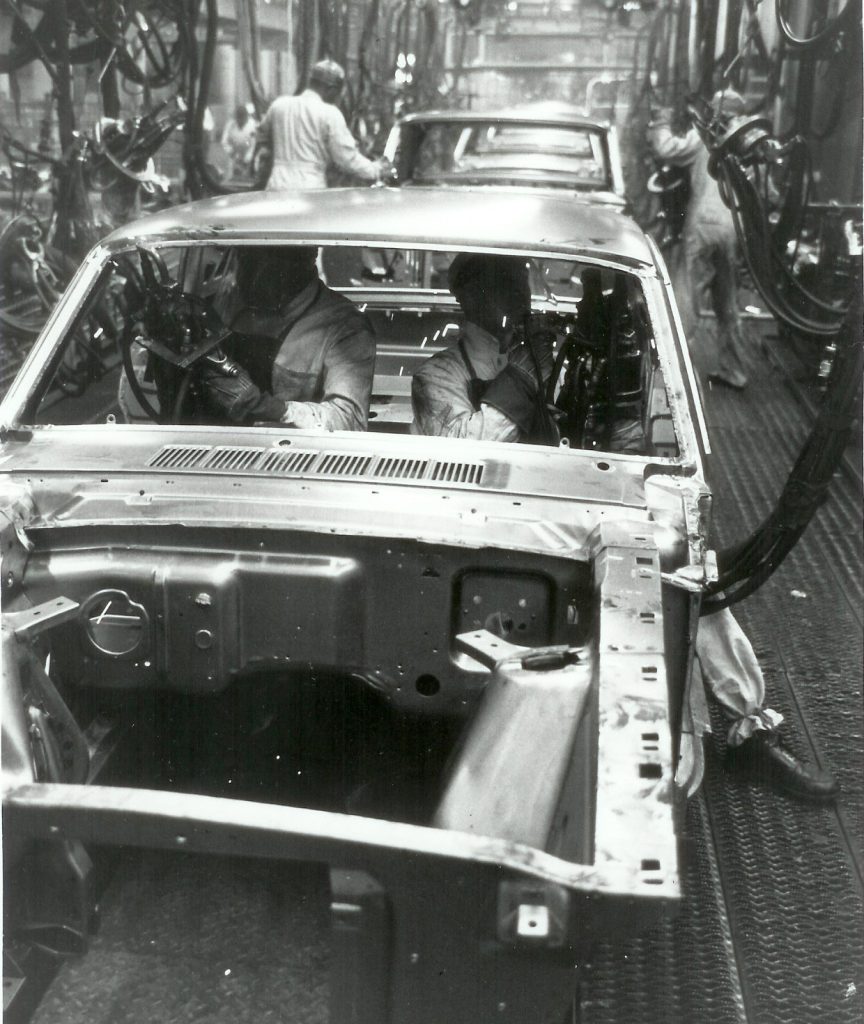

There were two rotation numbers—one for the body line and another for the trim and chassis line. The body line was where steel bodies were bucked and welded together on a jig, then placed on assembly skids to be primed and painted. The trim and chassis line was where painted bodies entered the process of becoming finished automobiles.

Early in production, it appears the rotation/sequence numbers were alphanumeric (A12, A15, etc.) and grouped in lots. These numbers became a three-digit system that began with 001, 002, 003, and so on. At the Dearborn plant, the numbers were located on the radiator core support until the end of the 1965 model year, when they were stamped in the body buck tag. That made it easier to see how each vehicle should be built. When the numbers were etched into the radiator support, they were often hard to read. That led to vehicle assembly errors.

The Metuchen, New Jersey assembly plant always used buck tags. The San Jose, California plant used the buck tag for a limited time at the end of the 1970 model year and never used it again.

The First Mustang Built

Despite extensive research, no one knows what the first Mustang built was because factory records and images of this historic event are gone. Was it the first prototype? The first pilot car? The first pre-production or mass-production car? First Mustang claims have never been proven with legitimate factory documentation.

When Jim Haskell and I authored the Mustang Production Guide, Volume 1 30 years ago, we erroneously stated mass production began March 9 with VIN number 5F08F100001. Ford’s official position from 1964 reinforced our statement, but no one knows what date the car was bucked and assembled. We do know that 5F08F100001 had a sequence number of #84, making it the 84th pre-production car produced. It was also the first Mustang ever ordered—we’ll cover that next.

The First Mustang Sold

Ford did not permit dealers to sell Mustangs before the April 17, 1964 introduction date, but some did anyhow. No one knows many dealers took deposits and payments in full for Mustangs before that day, but we at least two Mustangs were sold on April 11, 1964. Unit 5F08F100001 was the first ever ordered. It was sold to Captain Stanley Tucker, a Canadian airline pilot. He walked into the John Parsons Ford dealership in St. Johns, Newfoundland and bought the Mustang from salesman Harry Phillips. This car is now on display in the Henry Ford Museum in Dearborn, Michigan.

The other Mustang purchased on April 11, 1964 was sold by a suburban New York area Ford dealership (District Sales Office 15, Newark). It has a scheduled build date of April 4, 1964 (04D). I’ve seen the owner’s manual with all of the original purchaser’s information inside.

Gale Wise is the only known surviving original owner of a Mustang purchased before the April 17 introduction date. She purchased her car on Thursday, April 16, 1964 at Johnson Ford on Cicero Avenue in Chicago. 22-year-old Gale hit pay dirt when the salesman allowed her to peek at a Mustang convertible they had covered up in the service department. When he rolled the tarp off, she fell in love with the Skylight Blue droptop and bought it. She has been driving it ever since.

I invite your feedback to see what we can further learn about these cars. As always, I invite your questions, thoughts, and discoveries–email me at jimsmart.jbjmediagroup@yahoo.com.

Comments