I’ve been working on cars for over 50 years. During that time, I’ve had two close calls with cars falling off jacks and jack stands. The first involved preparing the underside of a stripped 1969 Camaro shell for paint. I thought I had it properly balanced on four jack stands. While I was under the car cleaning and scrubbing, the front end started to lift off the jack stands and teeter rearward. It was all I could do to bench press the thing to keep it from falling on me.

Luckily my seven year-old daughter heard the commotion and came to see what her dad was up to. The little bit of extra strength she had was enough to help rebalance the car. Man, was I lucky.

The next close call came recently with my Nova. I’ve put Novas up on jack stands and ramps hundreds of times, but this time I made a dumb mistake. While jacking up the front of the car, I neglected to shift the transmission into neutral. As the jack went up, the car couldn’t roll with the upward motion. And for whatever reason, the floor jack didn’t roll either. Only one thing could possibly happen in this situation—the car slipped off the jack. Fortunately, there was little or no damage except to my pride.

I’m sure many of you have similar stories. To help all of us avoid such stories in the future, we’ll outline some steps to properly to safely lift and put a car on jack stands.

Lifting the Front of the Car

I always make it a practice to jack up the front of the car before the back. Basically, I’m lifting the heavy end first and securing it. Based on my experience, make sure the transmission is in neutral and that the parking brake is disengaged before lifting the nose of the car.

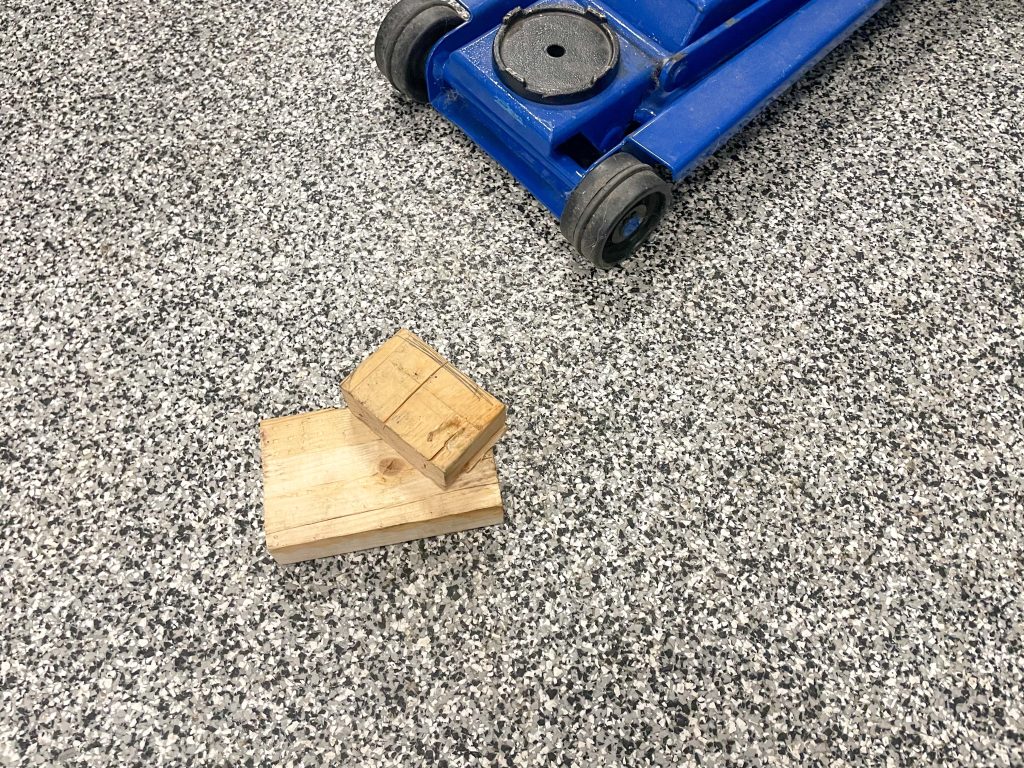

Many cars have a crossmember under the engine that you can use as a jacking point. The issue with this is that the crossmember can deform as you lift the car with a floor jack. I use a 12- to 18-inch long piece of 2×4 lumber between the floor jack pad and the crossmember to spread the load and avoid damage.

I like to use ramps to hold front of the car in the air. I don’t drive the car onto the ramps—I use a jack to lift it and place the ramps under the front tires. If you have a car with a full frame or a subframe like a Nova or Camaro, you can also place jack stands under the frame rails for extra security. Keep in mind that might make it harder for you to get under the car.

Lifting the Rear of the Car

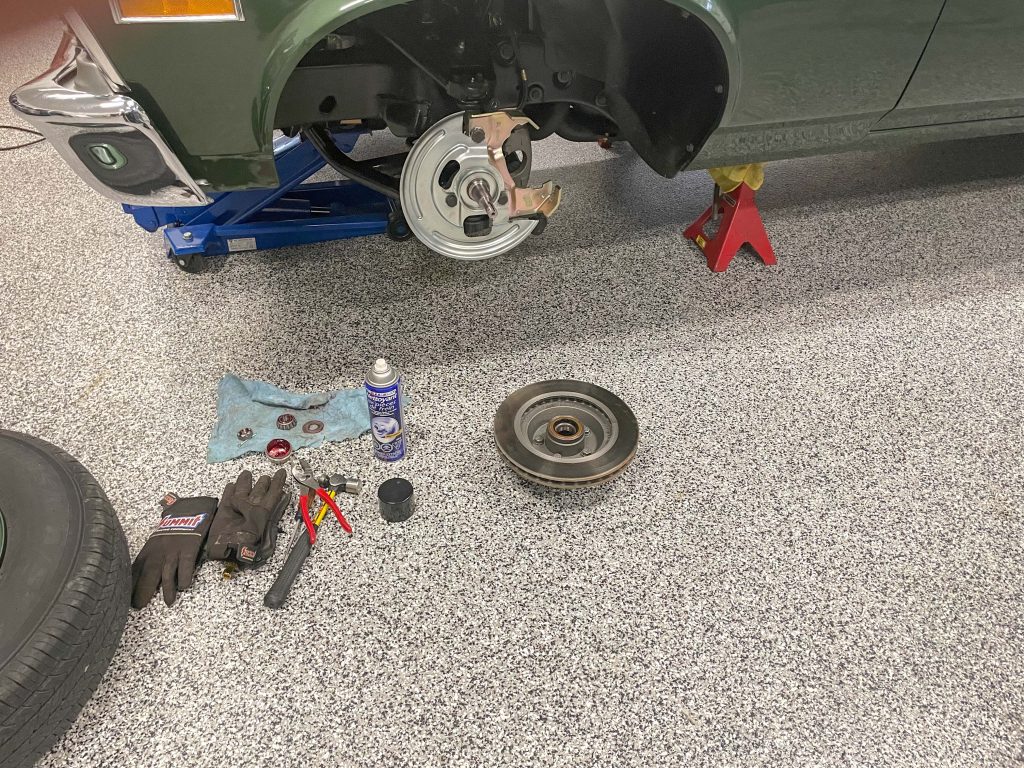

Out back, I always place the floor jack under the center section of the rear end and place a jack stand under each axle tube. You can also place the jack stands under the frame rails or subframe connectors if your car has those.

Some cars like my Nova don’t have a lot of room at the rear of the chassis. In my case, I have a rear sway bar that rotates as the car goes up and interferes with the floor jack. To fix this issue, I place a block of wood between the jack pad and the rear axle housing.

Lifting the Car from the Side

Another option is to jack up the car from the side. Jack up one side, place the jack stands, then do the same on the other side. Be cautious here as it’s easy to lift too much. It’s a very good idea to place chocks ahead of the front wheels and behind the rear wheels. Make sure to put the transmission in park or in gear in the case of a manual (first gear when lifting the front of the car and reverse when lifting the rear).

Later model cars (especially unibody cars) are engineered with reinforced areas in the body/rocker panel seams that act as jacking points. You can use those to lift the car and position the jack stands. Use a good floor jack instead of the scissor jack supplied with the car. It will slip if you lift the car further than needed to remove the wheels and tires.

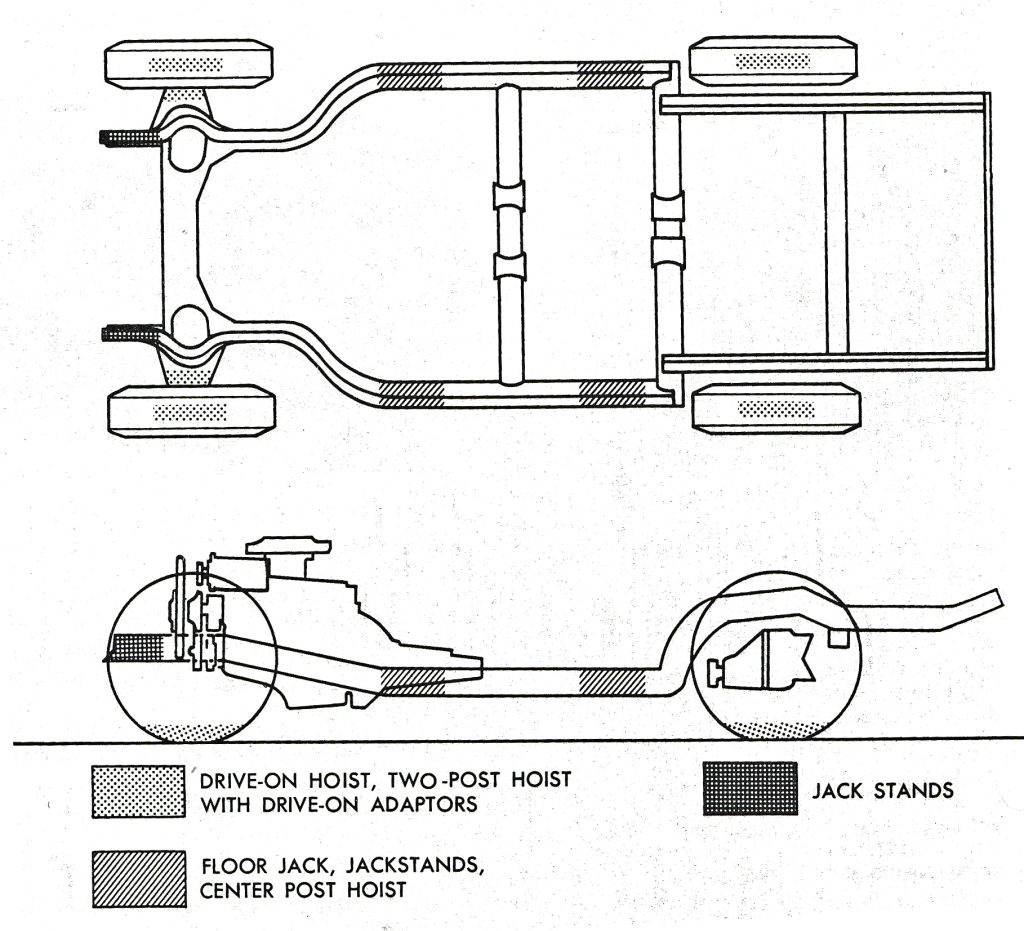

Some cars have special jacking instructions. Case in point are vintage Corvettes. Some have six jack stand points—two ahead of the rear wheels, two behind the front wheels (where the frame is level), and two at the front of the frame ahead of the engine. I’ve attached a Chevrolet Service Department image showing the locations.

Other Considerations

When the car is finally positioned on jack stands, you absolutely must give each end a shake to ensure the stands are properly engaged and secure. I use an upward and side to side motion when giving the car the ‘jiggle test.’ It’s a good idea to use jack stand pads to spread the load. This is particularly important if you want to avoid marring a well-detailed chassis.

I always leave the floor jack under the rear axle housing or under the nose depending on where I’m working, even when the car is settled on jack stands. I keep the floor jack engaged for added security should something go wrong. My daughter isn’t here to help if I get into trouble again!

Never, ever trust a floor jack or even a pair of them without using ramps or jack stands. Why not? You’re relying on a fifteen cent seal to keep the jack functional. If the seal fails, the jack collapses. You know what happens next.

If you use ramps under the front wheels without jacking up the rear, make sure to chock the rear wheels to ensure the car doesn’t roll off the ramps. It can and does happen.

Avoid using jack stands on a soft surface like dirt or gravel. If you have to do so, place sections of plywood under them so they won’t sink into the soft surface. Doing the jiggle test mentioned above is doubly important when working on soft surfaces.

As you can see, there are simple things you can do to stay safe when working under a car. Taking the extra minute or two to practice safety sure beats a trip in an ambulance or spending time in a cast—or worse.

Words of wisdom. Thanks Wayne