Valve springs are probably the most stressed components of an engine.

Yet they are also one of the most oft-overlooked parts in the entire engine.

The fact of the matter is valve springs are among the most critical pieces of an engine assembly, essentially acting as the glue that holds the entire valvetrain together. By choosing the wrong set of valve springs, you can severely limit the power output of your engine and even cause catastrophic damage. That’s why it’s important to select the right valve springs for your application.

Determining the right spring starts with figuring out the correct installed valve spring height.

What is Installed Height?

The installed height of a valve spring is the total height of the spring when the valve is closed. It is measured from where the spring meets the bottom of the retainer to where it rests against the cylinder head. All camshafts come with a recommended valve spring height; it is usually on the spec card included with the cam. If you follow that recommendation, you will have a spring that is not too weak (causing the valves to float at high rpm), or one that has too much spring pressure (which can wipe a lobe off the cam).

Now that we mentioned spring pressure, we’ll quickly discuss the two basic types.

- Seat pressure is the pressure the valve spring places on the valve when it is in closed position.

- Open pressure is the spring pressure that forces the valve to close after the rocker arm pushes it open during the combustion cycle.

As you probably guessed, open pressure is greater than seat pressure. According to the folks at Lunati, seat pressure for non-roller hydraulic cams should be around 300 pounds maximum (350 pounds for non-roller mechanical cams). Seat pressure should be about 110-120 pounds maximum (140 pounds for mechanical cams). Roller cams are another story.

Because it moves the valve at higher velocities, a roller cam requires a spring with more seat pressure to prevent valve float. Also, rollers don’t have the scuffing associated with flat tappet cams and lifters, so springs with higher open pressures (around 500-800 pounds at peak valve lift according to Lunati) can be used to let the engine rev higher.

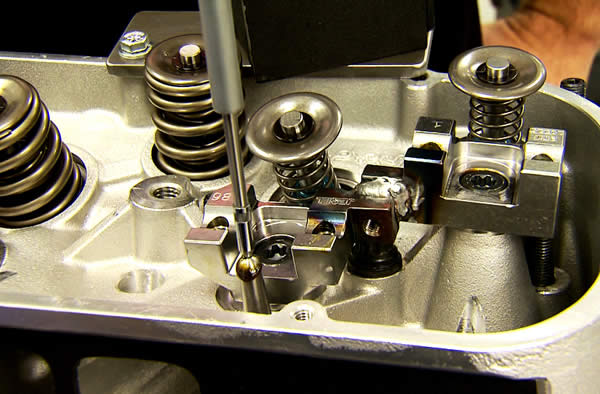

Checking Installed Height

Most cam grinders offer springs matched to their camshafts. We recommend you follow these manufacturer specifications. But it doesn’t matter if you use springs matched to your cam, are running different springs, or are changing springs—you must check the installed height to make sure it matches what the cam card says. There are two ways to measure installed height:

- Using a good mechanic’s ruler, measure the spring from where it meets the bottom of the retainer to where it sits on the cylinder head. DO NOT INCLUDE THE THICKNESS OF THE SHIMS.

- Use a valve spring height micrometer. Much more precise than a ruler, the micrometer replaces the spring itself. All you have to do is turn the dial until the valve is seated snugly in its seat, then note the measurement. If the spring is not at the recommended installed height, you will either have to shim it until it reaches the proper height, or you can machine the spring pocket in the head deeper to get the installed height you need.

If you go to a spring with a larger diameter than stock (common with bigger cams), you may have to machine the spring seats on your cylinder heads. Also, if you change from a spring with a rotator to one without, you will need to change to the recommended retainer to avoid changing the installed height.

But the power and higher capacity will be well worth the trouble.

Hi!

I bought isky 201070 cam.

came without the cam card and i don’t know what valve spring pressure should i use!

I have already sent several emails to Iskenderian and got no answer .

As I live in Brazil is difficult call Iskenderian.

Can anyone help me?

Thank you!

mechanical flat tap (solid) 304/304

.50 = 264/264

lift .548/.548

lobcenter 108

3500/7500

The recommended spring for this cam is a part number ISK-6005. All information for this spring is listed on the Summit Racing website. Closed pressure is 135 lbs. and open pressure is 285 lbs. Hope this helps.

way to low open pressureshoul be 350

sorry thought we were talking mechanical roller disregard first reply

looking for installed vaule spring height for 2006 3.0 v6 ford engine

[…] to know the height of uninstalled springs, to be sure that they are not "tired". Here's the link:Valve Spring Installed Height: Why It's Important and How to Measure It – OnAllCylinders To an article that seems relevant to the […]

This combo is also such as the Immediately Flush as these cards has

to be in sequential sequence but the distinction is don’t have

to be in almost any unique match.

Please, quote:

SPRING, VALVE: VALVE SIZE 42 IN, MATERIAL SS ASTM A313 GR TP302, FFT:MODEL # TK2-Y 42″ ANSI 150 #(qty 1)

I think there is something wrong here: “According to the folks at Lunati,seat pressure for non-roller hydraulic cams should be around 300 pounds maximum (350 pounds for non-roller mechanical cams).Seat pressure should be about 110-120 pounds maximum (140 pounds for mechanical cams).” Don’t you mean that OPEN pressure should be around 300 pounds maximum (350 pounds for non-roller mechanical cams).

You are 100% correct

HEY THERE, I HAVE A mid -late 90s chevy ZZ4 350 engine,it had low miles on it so we honed out the cylinders but used the factory Pistons connecting rods and pushrods,i bought new hydraulic roller lifters and rockers and a bigger cam the mechanic used the factory valve springs. So i’m trying to determine if these springs are sufficient, been told i need to find out what the installed height of the heads are and also measure spring pressure then should know if these springs are strong enough are not. The cam card is as follows:intake cam lift 0.3750, intake valve lift 0.5625,intake duration 222.0,exhaust cam lift 0.3540, exhaust valve lift 0.5310, duration 230.0, grind:CHS-154-28-12HR, cam came from gs products phone# 717-838-4767. Factory cam as follows:valve diameter intake/exhaust 1.94/1.50, valve lift intake/exhaust .474/.510, duration intake/exhaust 208/221 degrees@.050 tappet lift, rocker arm ratio 1.5:1, would you have an idea of what valve springs i need for this new cam?

this article is useless. Looking at the diagrams included it doesn’t show weather the locator is included or not. that makes a big difference. now the auther make think that everyone show know the answer weather the locator should be included but that would be a short coming on their part. So what’s the answer? do i include the locator or not in the installed height?

put on locator you are going to use and retainer measure between locator top and retainer bottom gives u wat the installed height u have to work with or leave out locator and add the thickness to measurment . different locators and retainers have different thicknesses use micrometer to measure very simple dont overthink it, god bless

First of all, learn how to spell, and next, why don’t you try appreciate the fact that someone took the time to write this article to try to help people. All this engine info on the internet is FREE! It’s almost limitless, it’s at your finger tips, and it’s FREE!

Show a little gratitude.