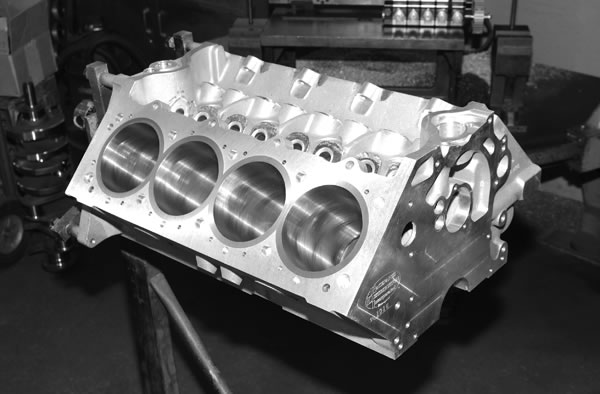

The foundation for our build is this Ford Racing 429/460 aluminum block. It weighs a mere 179 pounds and can be bored and stroked up to 598 cubic inches (and yes, we rounded up to get 600). Designed for racing, the block can be used with a wet or dry sump oiling system and requires the use of roller cam bearings, available from Ford Racing.

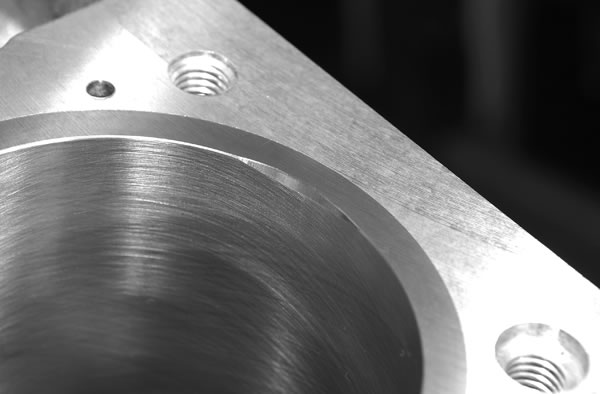

The block comes factory-fitted with .180 inch thick cast iron cylinder liners, which can handle a bore job up to 4.625 inches. Evanuik Racing Engines went with a 4.560-inch bore and 4.500-inch crank stroke to get to 600 cubes. The small chamfer in the liner is called a bore notch. It helps better match the bore to the shape of the combustion chamber in the Trick Flow A460 cylinder head, and unshrouds the valves for improved airflow.

Since the 600 would use a dry sump oiling system, the oil return holes in the lifter valley were enlarged, and the areas leading to them were contoured to promote better oil drainback to the crankcase.

The lifter bores had to be knocked down approximately .150 inch to clear the link bars on the Comp Cams roller lifters. The pushrod notches were also enlarged to make sure there would be no interference problems.

With such a long stroke (4.500-inch vs. stock 460’s 3.850-inch), block clearance problems were a given. Approximately .250-inch had to be machined away from the area around the bottom of the cylinder bores to clear the Crower crank’s counterweights.

The main bearing bulkheads required some minor grinding to clear the Crower crank’s thick counterweights.

The Ford Racing block comes with these four-bolt billet steel main bearing caps. ARP studs are used on the inner holes, with ARP capscrew-head bolts on the outers.

The main cap studs have a unique bottleneck design. The studs bottom on the round end to prevent thread damage and for better torque retention in aluminum blocks.

Crower was kind enough to whittle the 4340 billet steel crankshaft for the 600 stroker project. The fully CNC-machined arm is based on the company’s standard 460 crank, so it retains the factory 3.00 inch main journals and 2.20 inch connecting rod journals. Of course, the entire reciprocating assembly was balanced. Don’t ask how many slugs of Mallory metal it took….

The forged pistons were custom-made by JE Pistons. The dished pistons have a 1.350-inch compression depth; static compression with the 91cc chambers in the Trick Flow A460 heads is around 10.4, just within the limits of 94-octane pump premium. The connecting rods are Crower's Billet Series. The 4340 steel rods are 6.7 inches long, and have additional cam-to-rod clearance machined in for use in stroker combinations.

Evaniuk Racing Engines drilled small “troughs” for the double pin oil holes in the oil ring land just above the wristpin bore. The rings themselves are from JE (.043- inch top, 1/16-inch secondary, 3/16-inch oil control).

Test-fitting of the reciprocating assembly in the block found a clearance issue with the connecting rod bolts. Time to break out the die grinder..

Big cubic inches love big cams, especially when there is a manual transmission to keep things stirred up. This Comp Cams solid roller camshaft specs out like a drag race grind. Duration at .050 is 264 degrees intake/274 degrees exhaust (308/318 degrees advertised); lift is a whopping .751 inches intake/.720 inches exhaust. Fortunately, there are 600 cubic inches to tame this cam for street use.

Trick Flow sent a pair of its A460 aluminum cylinder heads. As delivered, the heads have 340cc intake/172cc exhaust ports, 91cc chambers, 2.300-inch intake/1.88-inch exhaust valves, 1.640-inch double valve springs with titanium retainers, and machined valve locks, guideplates, and rocker arm studs.

Jim Evanuik did some basic cleanup on the combustion chambers. He opened up the side walls to match the large cylinder bore for increased air flow. Sharp edges were deburred to help prevent detonation, and the spark plug holes were for better plug firing.

The heads required some modification to work with the dry sump oiling system. An additional oil drainback hole and a milled slot were added to help drain oil more quickly off the top end of the engine and back to the crankcase. That oil is crucial to keeping the main and rod bearings supplied with lubrication.

The decision was made to go with a dry sump oiling system for the 600. The overriding reason was clearance. The engine had sit as low in the car as possible for the tunnel ram induction system to clear the stock hood, which in turn created ground clearance issues. Since a dry sump oil pan can be made much shallower than a typical wet sump pan, that clinched the deal. A call to Stef’s Fabrication Specialties resulted in this aluminum pan. At 7 inches deep, the pan solved the clearance issue nicely.

A set of 1.7-ratio Crane Gold Race roller rocker arms and 3/8-inch COMP Cams chromoly pushrods transfer cam motion to the valvetrain.

Because there is no oil pump to mess with, Stef’s gave the dry sump pan a full-length, screen style windage tray for oil control. That means extra horsepower due to the increased ability to keep oil off of crankshaft.

As with most custom applications, the oil pan needed a touch of clearancing to fit—in this case, minor notching to clear the rear main bearing cap as indicated by the black line.

The oil pump is a Stef’s SCP five-stage (three scavenge/two pressure) belt drive unit, plumbed with Earl’s -12 AN braided hose and fittings. The dry sump system not only solved the clearance issues, it will help boost power through reduced oil aeration and superior oil pressure and volume control.

The remote-mount oil filter plumbs into the engine through the block’s oil filter mounting pad fitted with a -12 AN adapter fitting.

EFI? Bah. Nothing says horsepower like a tunnel ram with a pair of big ol’ Dominators. The Evanuiks chose Trick Flow’s A460 aluminum tunnel ram ’cause it’s designed for big cubic inch, high-rpm engines like the 600. It has bosses for both nitrous oxide and fuel injection, too.

A pair of 1,050 cfm Holley Dominators will perch atop of the modified tunnel ram. The stock cowl was modified to duct cool air to the carburetors. With the air cleaner in place, there is less than half an inch of clearance between the hood and the top of the cleaner!

How cool is this—a distributorless, coil-on-plug, digitally controlled ignition system that mounts everything under the dash? The MSD CPC Digital Ignition (MSD-7600, available by special order from Summit Racing) controls the spark; it can be programmed via a laptop PC to adjust individual cylinder timing, vacuum advance, rev limiters, even boost curves for forced induction. The MSD coil packs are mounted to the dash bar, and route the spark to the engine through the bulkhead connectors in the center. The only ignition components under the hood are the MSD crank trigger, the plug wires, and the spark plugs.

Jim Evanuik Jr. put together a serpentine front accessory drive system using components from Billet Specialties. The only items not mounted in this photo are the A/C compressor and the power steering pump, as they were not required to dyno-test the 600.

Jim built the trick little idler pulley setup using a March idler. The alternator is one of MSD’s Advanced Power System (APS) units. The 160-amp alternator has a CNC-machined billet aluminum housing, extreme duty windings to handle heavy current loads, dual ball bearings, and an external voltage regulator that can endure high heat conditions.

The Billet Specialties crankshaft pulley required some modification to work on Jim’s accessory drive setup. As you can see, it was literally machined in half!

Here’s why the pulley had to be cut down—there’s a lot of stuff hanging of this crank snout. From the back (closest to the block) is a Fluidampr harmonic damper, the MSD crank trigger, the oil pump drive pulley, and the Billet Specialties crank pulley.

With all of our pieces-parts assembled into a 600 cubic inch whole, it was time to strap the engine on the dyno. Jim Evanuik Sr. improvised some 460 engine mounts to fit the 600 on his dyno stand.

Jim Evanuik Jr. checks the runout on the Hays billet steel flywheel. It was well within tolerance at .002 inches. Hays supplied the clutch disc and pressure plate as well.

The flywheel also required some minor balancing to make it truly neutral balanced. You can see where material was drilled out at the upper left.

Jim Sr. double-checks the engagement pattern and depth of the dyno stand input shaft where it fits into the crankshaft. If the shaft does not engage properly, the result can be a chewed up pilot bearing—or worst case, a busted crank.

With the reservoir filled with oil, the Stef’s oil pump is turned over by hand to prime the engine prior to startup.

The tale of the dyno chart—920 peak horsepower and 810 ft.-lbs. of peak torque. And The torque curve never dipped below 686 foot-pounds from 4,500 rpm on up.

We can remember a time when a big block that pushed 500 cubic inches and 700 horsepower was just short of unbelievable. Heck, that’s small block territory nowadays. If you really want a powerplant that gets your car noticed, you have to push way past that.

And 600 cubic inches and 920 horsepower worth of all-aluminum big block Ford will definitely get you noticed.

As you might have guessed, building the 600-cubic-inch big block involved some creative thinking too. The engine had to meet some very tough criteria:

- Make at least 900 horsepower

- Be streetable with a broad, usable torque curve

- Operate on premium pump gas

- Use as many off-the-shelf components as possible

To fill this very tall order, we went to Evanuik Racing Engines in North Versailles, PA. Jim Evanuik and his son Jim Evanuik Jr. are well-known for their drag and circle track motors, and they hit the parts books and put together a combination to meet our street performance requirements.

Block and Reciprocating Assembly

If you want an all-aluminum big block Ford, there is only one foundation to use—Ford Racing’s 429/460 Race Block. Cast from 356-T7 aluminum, the block weighs a mere 179 pounds, and can support up to a 4.625-inch cylinder bore and a 4.600-inch crank stroke. The block has 4-bolt billet steel main caps, cast iron cylinder liners, and uses roller cam bearings. Quite the stout piece.

Crower supplied a 4.500-inch stroker crankshaft and a set of 6.7-inch long Pro Mod billet connecting rods. The crankshaft and rods are CNC-whittled from 4340 chromoly steel and are strong enough to support well over 1,000 horsepower. Rounding out the reciprocating assembly are custom-made JE forged pistons. The pistons have a .350 dish to produce 10.4:1 static compression with the 91cc chambers in the Trick Flow PowerPort A460 cylinder heads.

Camshaft

Big power and cubic inches dictate a pretty radical cam. The Evanuiks speced out a COMP Cams solid roller camshaft with 264/274 degrees duration at .050 (308/318 degrees advertised duration) and .751/.720 inches of lift. It sounds pretty hairy for a street car. But keep in mind the engine’s large displacement and the fact SR61 has a Richmond Gear six-speed manual transmission, and the cam makes more sense.

Cylinder Heads and Valvetrain

The heads are Trick Flow Specialties PowerPort A460s. The aluminum heads feature 340cc intake and 172cc exhaust ports, 91cc chambers, 2.300-inch intake and 1.88-inch exhaust valves, 1.640-inch double valve springs with titanium retainers, and machined valve locks, guideplates, and rocker arm studs. The rest of the valvetrain consists of Comp Cams roller lifters, 1.7-ratio Crane Gold Race roller rocker arms, and Comp Cams chromoly pushrods.

Induction System

Electronic fuel injection offers superior drivability and efficiency compared to dinosaur-era carburetion. But nothing looks more intimidating—or sounds better at full throttle—than a pair of Holley Dominator carburetors on a tunnel ram. The Evanuiks went with 1.050 cfm Dominators and a Trick Flow A460 tunnel ram to satisfy the 600’s big appetite for air and fuel. This setup may not be as precise as EFI, but with 800-plus ft.-lbs. of torque on tap, who needs precise?

Ignition

The spark-processing system for the 600 is as high-tech as it gets. The distributor-less system features an MSD crank trigger unit and eight Blaster coil packs controlled by a programmable MSD CPC digital ignition box. You can program the CPC system’s timing curve, individual cylinder timing, boost timing curve, vacuum advance, rev limiters, and a host of other parameters via a PC and MSD’s Pro Data Plus software. The CPC ignition and coil packs are remote-mounted under the dash; the only things you see in the engine compartment are the plug wires.

Oiling System

There were two concerns when it came to the 600’s oiling system. The first was efficiency—having enough petroleum to keep the engine well-lubricated without drowning the crankshaft and causing drag and oil aeration. The second was clearance—no way was a large capacity, wet sump oil pan going to offer enough ground clearance for the lowered 1961 Ford Starliner for which it was destined.

The solution was a dry sump oiling system, consisting of a Stef’s aluminum oil pan, four-stage gerotor oil pump, and 12-quart oil reservoir tank. The shallow pan provides plenty of clearance, and with most of the oil held away from the crank, oil foaming and drag are virtually eliminated.

Exhaust System

The big block’s 2 1/8- to 2 1/4-inch stepped primary headers were fabricated from stainless steel. The header tubes run parallel to the ground for clearance and dump into fabricated flat collectors built directly into the Flowmaster Delta Flow mufflers. The rest of the exhaust is NASCAR-style flat oval “boom tubes” from Dr. Gas.

Other Stuff

That covers the big Ford’s heavy artillery. But other, perhaps less flashy components should also be mentioned. For example, Jim Evanuik Jr. built a serpentine belt front accessory drive system virtually from scratch. The alternator is one of MSD’s APS units, and the harmonic damper is from Fluidampr. The plumbing is all stainless steel braided

hose and AN fittings from Earl’s.

What Does She Make?

A lot, actually. Strapped to Evanuik Racing’s Superflow dyno, the 600 made huge power from the get-go. After break-in and an oil change, the first power pull netted 900 peak horsepower at 6,500 rpm and 795 ft.-lbs. of torque at 4,500 rpm. After some fiddling with the Dominators and timing, the 600 hit the mark—920 horsepower at 6,700 rpm and 810 ft.-lbs. of torque at 4,500 rpm.

Video? I wanna see it run!

are there any videos on this motor?

Is this for nitrous

Fritz marine engineering did this withe the cast iron SVO four bolt splaid main caps in 1990…we put a pair in a Ross Perot 40 foot fountain power boat….

wondering if any boss head testing has been done

What is a svo 385 block

What was the cost of the build

Hello, serious question. Is it enough this small holes for cooling to cool this big engine?? Like some chevy blocks have 3 small holes to each cylinder bank for cooling entire block.. I still do not understand, how they take heat from cylinders, egz. mostly modern engines have at least 20,30% cooling area around cylinders.. Im very curious, would be very good if somebody who knows engines, would explain how they cool enough and do not blew..

where can I purchase one of these 460 aluminum blocks not available at ford racing

Kaase racing engines

Actually whenn someone doesn’t know then its up to other people that they will help, soo here

it happens.

Nice set up I love it big block ford

where can i buy a complete 600 built engine please tell me thank you

you built yours from a 460 but what about the old 534 big block ford engine i have seen many in tandem axle farm / grain trucks would it not be better to start with as large a block as you can get then go up from there

How much money did you have in the engine once it was built?

Where can I purchase this block?

Okay are these kits getable as far as i can tell are blocks are hard to find or not availble sure be interested to know

Are these kits avalible as gar as i know blocks are very hard to find or not availble