The transmission is the little brother of the powertrain.

The transmission is the little brother of the powertrain.

It doesn’t often get the same respect or attention as the engine—until it starts acting up. You’ll most likely see dozens of engine build stories in magazines before you see an article on a transmission. And we spend hours under the hood or around an engine stand in an attempt to wring every last bit of power from an engine.

Of course, all that is power basically useless without a good transmission to put it to the pavement. To get you thinking about your transmission and its importance to your vehicle’s performance, we’ve compiled a list of the most common transmission questions, according to the Summit Racing tech department. (Yes, the Summit Racing guys were kind enough to supply the answers too.)

In a later post, we’ll help you diagnose common transmission issues and sounds, so you can get your tranny working properly. For now, let’s answer the basics:

How do I identify my transmission?

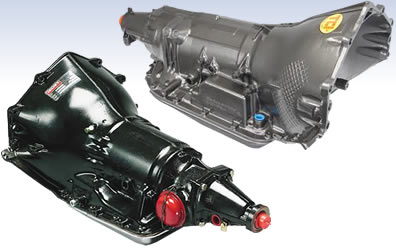

There are two basic ways to identify your automatic transmission: transmission pan shape and overall transmission dimensions. You can check out this earlier OnAllCylinders post for transmission dimensions and a slide show of different transmission pan shapes.

Manual transmissions are little bit harder to distinguish, so the Summit Racing guys often turn to Hurst, which has an assortment of diagrams to help ID a manual tranny. To figure things out on your own, you can view the diagrams by clicking the links below:

What are the dimensions of my transmission?

If you’re trying to fit a different transmission into your chassis, or if you’ve got a custom project in the works, you’ll need to measure the tranny to make it fits. Summit Racing put together a chart with the dimensions of popular GM, Ford, and Chrysler automatic transmissions. Check it out.

What do shift kits do? Why do they make the transmission shift harder?

Shift kits simply eliminate many of the restrictive oil flow problems in the transmission’s valve body. The results are firmer shifts and reduced slippage and shift overlap.

I want to install a shift kit into my transmission…which one should I install?

The easiest and least expensive way to improve the shifts of your automatic transmission is to install the Shift Improver Kit. If you want additional manual control of the transmission, you would choose the B&M Transpak. If your transmission needs an overhaul, the Transkit is your best choice.

I want to install a TH-700-R4 transmission into a vehicle that doesn’t have a computer. What will I need?

There are several components that will allow this type of installation. The Converter Lockup will allow converter lock-up operation in non-stock applications. You should also consider the B&M TV cable, which can be used for conversions as this is an adjustable length cable. B&M also offers a linkage adapter kit that can be used to position the TV cable. This adapter will save a lot of fabrication.

How does a trans-brake work?

A trans-brake simultaneously applies low and reverse gears, which holds the vehicle in position. When the activation button is released the reverse hydraulic circuit is instantly dumped allowing the vehicle to launch.

Can a trans-brake be used on a street car, or is it strictly a racing product?

Trans-brakes are designed to achieve instant reaction times in competitive drag racing situations. They are rarely useful in street applications.

Should I use an external transmission cooler in conjunction with the oil cooler supplied in the radiator?

Unless operating in an environment where the outside temperature is below 0 degrees F, you should cap off the radiator cooler line openings and run your cooler lines directly to a new cooler mounted in front of the radiator. This allows the transmission to have its own cooling system and doesn’t allow the engine water temperature to heat the fluid.

Where should the transmission cooler be mounted?

Most transmission companies recommend mounting your external transmission oil cooler in front of the radiator. This allows for adequate airflow. If this is not possible, then you should mount it in a location where the cooler can receive airflow. In extremely tight quarters, you may also want to build an air dam to direct more air to the cooler.

What is the correct size cooler for my application?

Unlike a lot of items you buy for your vehicle, bigger is predominately better when it comes to transmission coolers. The answer is as big as you can get or to run multiple coolers in a series, again staying away from the factory radiator cooler lines.

What gear ratios do I need for my car?

Transmission ratios are based off the rear axle ring and pinion ratio. Optimum ratio is often determined by the intended purpose of your vehicle—daily driver, race car, street/strip—and Summit Racing offers a special Gear Ratio calculator to help you narrow down your choice.

I want to be able to cruise at higher speeds and still be in fourth gear with my TH700-R4 transmission. Can you help?

Most TH700-R4 transmissions downshift from fourth to third anytime there is more than half throttle applied (except Corvettes, and some Camaros and Firebirds). This makes it difficult or impossible to cruise at high speeds in overdrive.

To maintain fourth gear, you need a TH700-R4 Kickdown Kit or a Throttle Valve Plunger & Sleeve for 700-R4. The B&M TH700-R4 Kickdown Kit includes a sleeve and requires the use of a factory ’94’ plunger; plungers that are stamped ’94’ can be found in V8 Camaros, Firebirds, and Corvettes. The TCI Throttle Valve Plunger & Sleeve comes with the plunger and the sleeve. Installation of one of these kits will allow you to operate at approximately 85-percent throttle opening before the kickdown to third occurs.

Hi David, I read your Quick Guide to Differential & Driveline Noises. I have a 2013 Chrysler Town & Country that chirps when decelerating generally between 30-20 mph. Chrysler says “Normal Engine Noise.” but before that they thought it was the water pump and replaced it but to no avail. Seems to be getting worse and louder with only 4500 miles now. I would appreciate any thoughts you may have.

Philip Sidran

Miami, Florida

psidran@gmail.com

Within the past few years the Auto manufacturers have found that the greater electrical demand of all the electronics on newer vehicles call for larger, longer lasting alternators. These larger alternators have a much heavier “Stator assembly” (the part that is spun by the belt internally) which puts more pressure on the serpentine belts. This increased pressure is present during both acceleration as well as deceleration. The extra rotational weight could cause belt glazing and ultimately loss of traction, thus a chirping sound intermittently.

The O.E.’s solution for the problem in some cases has been the use of a one way roller clutch built into the alternator pulley. This allows the stator assembly to free wheel under decel conditions eliminating the chirp and premature wear on the belt. Now keep in mind that this type of pulley is much more expensive than the traditional pulley, therefore the manufacturers will not install them on every single new vehicle produced.

Here’s a suggestion: with only 4500 miles your dealer is obligated to identify and repair the source of the complaint. You may have to try another more sympathetic dealer too! The suggestion; ask them to change the serpentine drive belt and note changes if any to the chirping sound. Now, all this is assuming the last technician did his due diligence in checking other things such as body mounts, engine mounts and hoses and any wiring crossing over from the motor to the body that may be rubbing on something.

Isn’t the rotor the part that revolves and the Stator the stationary part of an alternator?