Before the Chevy small block engine became a popular engine platform for hot rodders, the Ford Flathead V8 ruled the streets, drag strips, and the dry lake beds. Looking into the long history of the modified Flathead, you can’t help but run across the Edelbrock name a few times. So, we reached out to Smitty Smith, Edelbrock’s Flathead expert, and asked him questions about the early days of aftermarket Flathead parts development.

OnAllCylinders: The Edelbrock Slingshot manifold was designed for the Flathead Ford. What brought that design about?

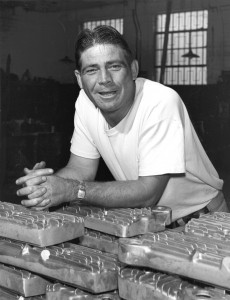

Smitty Smith: In 1938 Vic Sr. bought his first project car, a 1932 Ford Roadster. This car was the turning point in Edelbrock history. It was Vic’s entry into the world of “hot rods” and it inspired the design and manufacture of the first Edelbrock intake manifold. This is when he joined Tommy Thickstun to design the “Thicksun” manifold for the Flathead. When Vic wasn’t happy with the performance, he designed his own aluminum intake manifold. It was called the “Slingshot”. The Slingshot was a 180* manifold for the Ford Flathead using two Stromberg 97 carburetors. This was the first product to feature the famous “Edelbrock” name. Before the war, Vic produced about 100 of these Flathead Ford manifolds. Vic raced and tested his new manifold on his 1932 Ford at the dry lake beds, 80 miles northeast of Los Angeles (where Edwards Air Force base is today).

OAC: What was it about the Ford Flathead that left more to be desired?

Smith: Well as anyone might notice, the Ford Flathead only had three exhaust exits on each side, which means the center two cylinders on each bank shared the same center exhaust port on each bank. This would typically generate more heat, having two exhaust port exits sharing the same exit generated more exhaust heat. Another undesirable Flathead feature is the lower end of these engines only use three main caps to hold the crankshaft and rotating assembly in the Flathead blocks.

OAC: Vic Sr.’s project car was a ’32 Ford Roadster, what other modifications to the roadster did Vic do to get a little more speed?

Smith: In the early days before the war, Vic would drive his modified 1932 Ford Roadster up to the dry lakes and then remove the fenders, windshield, running boards and top, then he would run this car on the dry lakes and was clocked going 112 miles per hour. Then through testing, Vic added a vinyl cover on the passenger’s side to help with aerodynamics. Some competitors asked what the manual fuel pump on the dash was for. He, while driving over 100 miles per hour, would pump this mechanical pump through the steering wheel, and what was actually being pumped was a special mixture to help and assist him achieving higher speeds.

OAC: After the Slingshot intake manifold, Vic started making cylinder heads for the Flathead. What made these heads unique?

Smith: Vic learned before the war that there was what was called “Denver” cylinder heads. These cylinder heads were originally from Ford and the Ford Flathead did not run well at elevation, like in Denver, CO. Vic got his hands on some and he proceeded to fill and mill the head for a further increase in the compression, gaining even more power. After the war, Vic designed his first aluminum racing cylinder head for the Flathead Fords. Like the “Slingshot,” these heads were well received. The business was on the way to becoming more of a performance parts shop than a repair shop.

OAC: So Edelbrock makes cylinder heads and intake manifolds. What other Edelbrock performance parts can Flathead Ford owners find to customize their hot rod?

Smith: As the Ford Flathead was the engine of choice for many decades, Vic came out with more and more products for this platform. As the years progressed, he came out with 3-deuce intakes and even a 4-deuce intake for the Flathead, and eventually a single 4bbl intake was manufactured. Back in the day Edelbrock used to offer a lot of performance products from the norm, to pistons, camshafts, adjustable lifers and crankshafts. Now looking into today’s performance parts for the Flathead, some of those early day parts are no longer available today from Edelbrock. With all of the aftermarket companies, there are endless amounts of Flathead parts available today.

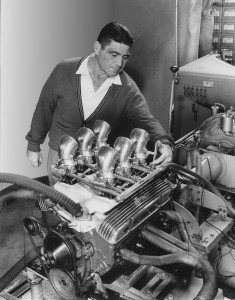

OAC: How did all of the learning and development of the Ford Flathead transfer into the next generation of small block Ford and Chevy engines?

Smith: Vic Sr. was truly a self-taught mechanic and became one of our performance aftermarket pioneers. He adapted what he learned from the basics of engines and especially from the Flatheads and adapted this to the new small-block Chevy in 1954 when Chevrolet introduced the 265 V8. Making more horsepower was the result of adding more compression to this new V8, then taking it one step further by lightening the rotating assembly of this little mouse. They all learned from camshafts on the OHV Chevy V8, the rocker arms were something new and for example the small block Chevy rocker ratio is 1.5. So you take the lobe lift of the camshaft and multiply that times the ratio. For example .300-inch lobe lift equals .450-inch at the valve. This is something the Flathead Ford did not have. On the cover of Hot Rod Magazine it was Vic Sr.’s 265 Chevy V8 that graced this issue with an outstanding achievement of 375 horsepower.

OAC: How has Edelbrock adapted from the single camshaft engine V8 to the dual-overhead cam with variable valve timing to still give car lovers the performance they are looking for from their late model engine?

Smith: Well, here we are moving up to our current performance offerings for late model vehicles. For what we call modern muscle, we at Edelbrock offer the most-advanced supercharger assemblies available for the aftermarket. Our superchargers deliver excellent horsepower and torque in a complete package that fits under the factory stock hood. We average a minimum of 100 to 180 horsepower above the factory stock rating. Our performance aftermarket products are designed, cast and made in the USA by Edelbrock.

You can explore the full line of Edelbrock parts for the Ford Flathead V8 engine here.

[wzslider autoplay=”true”]

I BOUGHT A 1938 FORD FLATBED WITH OUT OF ENGINE JUST HAVE A T10 TRANNY WITH OUT OF HOUSING IS 4 SPEED. WHERE I CAN FIND A COMPLETED MOTOR FOR MY TRUCK. I LIVE OIN FLORIDA .if YOU GUYS KNOW A PLACE AROUND HERE OR IS A WAY TO FIND ONE RUNNING IN GOOD CONDITION OR HOW MUCH COST ONE STOCK.CAN YOU GIVE ME SOME INFO IF YOU KNOW SOME ONE .THANK YOU VERY MUCH

Get busy and build one from parts….you can find them in a junkyard, even tho they are my favorite engines, my first car was 51 Mercury, 3 speed column stick with overdrive, I raced and beat many mustangs

[…] in the Buick Roadmaster was putting out 144 hp. It would take six years for Vic Edelbrock, Sr. to make the cover of Hot Rod for coaxing 375 hp out of a 265 Chevy […]

[…] in the Buick Roadmaster was putting out 144 hp. It would take six years for Vic Edelbrock, Sr. to make the cover of Hot Rod for coaxing 375 hp out of a 265 Chevy […]

[…] in the Buick Roadmaster was putting out 144 hp. It would take six years for Vic Edelbrock, Sr. to make the cover of Hot Rod for coaxing 375 hp out of a 265 Chevy […]

[…] In fact, the “Edelbrock” brand likely wouldn’t even exist were it not for the Ford Flathead V8; Vic Edelbrock Sr.’s first branded product was an aluminum intake manifold for the Flathead, dubbed the “Slingshot” (according to an interview published by On All Cylinders). […]

[…] THE ultimate hot-rodder, as it pretty much got the whole thing started when Ford gave us the first V8 Flathead tucked inside the ’32 Model […]

Hi I am restoring a 1931 ford and will keep it as original as possible except for the v8 flat head motor i need a adapter to hook up motor to 3 speed gear box do have or know where i could get one thanks Bundy

First, you need to procure some periods and proper punctuation for your comment.