It’s probably easier to pick a fuel pump for a Pro Stock car than it is for a street-strip machine. Think of the Pro Stock car for a minute: The fuel cell is most likely in the front of the car. That means the plumbing is short. The big pump can sit right beside the cell, and so can the filter. It’s not a long distance from the filter to the regulator and the return lines are short, too. There are four fuel bowls, and four needle and seat assemblies feeding 500 cubic inches.

Sounds simple enough to steal the technology and use it on the street, but there’s a hitch: Those big monster pumps feeding a Pro Stocker don’t like to running for extended periods of time. They consume a lot of electricity and before long, heat becomes a problem (this is really critical if the pump configuration doesn’t incorporate some form of return or by-pass system—deadheading pumps build heat in a hurry). Bottom line? The Pro Stock car has to run for maybe 15-20 seconds max before its returned to the pits (pushed to the staging lanes, burnout, stage, and follow up with a six and a half-second run, and then pushed back to the pits).

Where a drag race-only setup has to operate perfectly for a few seconds at a time, a street system has to function flawlessly every time—and it has to work for the long haul. If you have a street-driven weekend warrior sort of car—fuel injected or carbureted—then you’ll find yourself at a fuel delivery crossroad. If you have a big cubic inch engine between the fenders, or a power-adder or two (blower, turbo, nitrous, or even a combination of the three), fuel delivery becomes critical.

Modern fuel injection pumps are a different story. They’re designed so the fuel runs through them. Because of this, the fuel supply cools the pump as it operates, allowing the pump in question to function at maximum speed as necessary (usually until the tank runs dry). The trouble with many of these pumps is they don’t have the volume to feed big power engines. What’s needed is a big electric pump designed so that fuel runs through it.

It might sound a bit like “Mission Impossible,” but it’s not. Summit Racing offers a wide range of electric fuel pumps for street-strip applications (the online catalog shows 530+ examples). Not all are applicable for big power applications, so for this article, we’ll narrow it down and look at a MagnaFuel 625 pump, an Aeromotive Dual Phantom pump, and a Holley dual-inlet Dominator pump. All three are continuous duty pumps that will live on the street, and all three can handle big power.

MagnaFuel 625

First, let’s look at the MagnaFuel 625.

This pump is self-priming, and it can be mounted vertically or horizontally (mount bracket included) and it doesn’t have to be installed in the gas tank (although it can be). The pump is larger than the average OEM or replacement pump, measuring 7.50 inches in length (not counting the fittings or the by-pass). Taking the mount bracket into consideration, the pump measures just under 3.75 inches in height while the body diameter is three inches.

Internally, this particular pump incorporates double support bearings and uses polymer wear plates (which contribute to the low noise and smooth operation). The actual layout and construction of the pump eliminates the need for shaft seals. Without shaft seals, there’s nothing to leak (aside from an O-ring, which are usually reliable). This particular fuel pump is based around a high-torque custom motor with low current draw (12 amps at 45 PSI). This means you don’t have to wire in a relay for the pump (although you can). The MagnaFuel pump is completely rebuildable with a simple O-ring and wear plate kit.

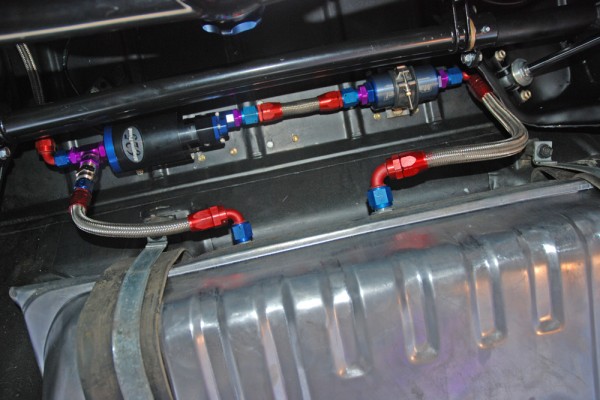

MagnaFuel’s 625 pump can be used in either fuel injected or carbureted applications. To make it work for carbs, MagnaFuel offers a bypass package for these pumps, and it is much like the system used in the big Pro Stock fuel delivery systems. It simply threads on the outlet of the pump. In operation, you set the final outlet pressure (from the pump to the regulator) you desire by swapping out by-pass springs. The balance of the fuel (excess) is bypassed and sent back to the tank. That process eliminates the “dead-heading” dilemma that can plague some pumps on the street.

Aeromotive Phantom Stealth

Next up is Aeromotive’s Phantom Stealth.

The Dual Phantom is engineered as a drop-in pump “system” for in-tank applications. According to Aeromotive, this is how it works: “Simply cut a hole in your tank and measure the depth. Cut your pump hanger bracket and baffle/basket foam to length. Insert the baffle, install the retainer ring and gasket, and bolt your pump and hanger down. That’s it. Now you have a fuel pump inside your factory tank capable of supporting big horsepower EFI or carbureted. And it’s whisper quiet. No more welding sumps or using up trunk space with fuel cells. No more hot fuel handling issues, like vapor lock, and no more fuel slosh. The Phantom’s internal baffle/basket controls fuel slosh and keeps the fuel pump submerged in fuel, even at low fuel levels and in aggressive driving. The best part about this whole system: it’s completely universal. This system will fit virtually any tank from 6 to 11 inches deep, plastic, steel, aluminum, corrugated, or smooth.”

From the mechanical perspective, the Dual Phantom is based upon a pair of 340 liter-per-hour (lph) pumps, an additional set of electrical bulkheads, along with a larger capacity foam and bladder. According to Aeromotive, the separate electrical bulkheads allow for an “on demand” fuel system, which reduces the amount of returned fuel, lowers the tank temperature, and pretty much eliminates both vapor lock and cavitation. This pump supports up to 2,000 horsepower (naturally aspirated and carbureted); 1,700 horsepower (forced induction and carbureted); 1,700 horsepower (naturally aspirated and EFI), or 1,400 horsepower (forced induction and EFI). All of the wiring hook ups are external. Additionally, the black anodized top hat is fitted with four -6 AN ports. Two are for the supply, one is a return, and the last is a vent.

Holley “Dual” Dominator

Holley’s big Dominator electric pumps are actually a pair of pumps twinned in one billet body. The concept allows you to make use of one pump for low-speed cruising. When the need arises (let’s say you really need to get on the power), you can flick the switch and turn on the second pump. This is an interesting option in the event you run a nitrous-assisted combination. You can run the engine on the first stage of the pump and then (automatically or manually) kick in the second pump stage when the nitrous is engaged.

Holley engineers have designed the big pump so that hot fuel handling capabilities are improved. It was engineered to greatly reduce the negative effects of heated fuel now common with many of today’s pump gas blends. The big Holley pump is available for use with pump gas or race gas. They also offer another model designed to work with E-85 or diesel.

Each of these Holley pumps weigh a total of 5.1 pounds, and with both sides of the pump engaged, the Dominator can deliver pressures up to 80 psi (which means that EFI is no problem). The pump draws 28 amps at full tilt, and the wiring was engineered so that it can handle inputs up to 18.5 volts.

The pump has a pair of -10 AN inlet ports along with a single -10 AN outlet port. In addition, the Dominator can be fully submersed in the gas tank. That means less plumbing and serious space saving. In terms of reliability, Holley advises that the pump has seen testing beyond 3,000 hours in a gasoline application.

As you can see, there’s a lot of choice when it comes to street-strip pumps. It’s not impossible to fuel some pretty healthy combinations with any of the pumps we’ve mentioned. Check the accompanying photos for a closer look:

Comments