Most of you guys with manual transmissions probably know if you have a cable-operated or hydraulic clutch release bearing. But how many with a hydraulic setup know what type you have, and if it’s the right one?

We spent a little time talking with Ram Clutches about hydraulic clutch release bearings. There are two basic styles: constant-contact (bearing always touching the clutch fingers) and intermittent (operates only when the clutch pedal is depressed) According to Ram, the intermittent style hydraulic bearing is better for high performance use. It has a greater adjustment range and is quieter than the constant-contact type.

High performance, intermittent style release bearings need to be properly gapped at rest. Excessive gap between the contact face of the release bearing and the clutch fingers causes improper release. Too little gap can cause the bearing to over-travel and collide with the snap ring, or cause slippage as the clutch wears and the fingers move back, making contact with the bearing.

Ram recommends single disc clutches have a 0.150-inch gap between the bearing and clutch fingers, while dual-disc sets require a gap of around 0.200-inch. The extra 0.050-inch gap for the dual disc clutch prevents the clutch fingers from hitting the bearing as the clutch discs’ friction material wears.

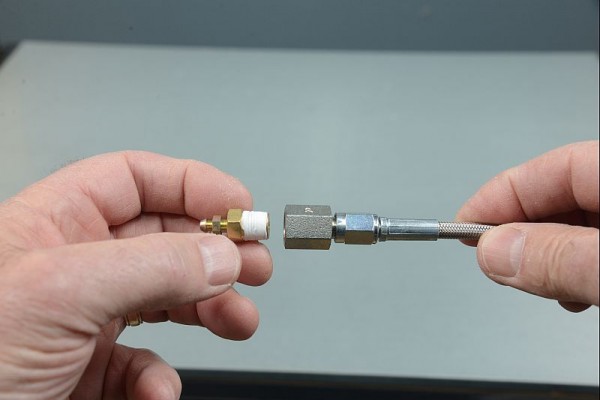

Follow along in the slideshow below to learn how to install and properly gap a Ram hydraulic release bearing on a single disc clutch.

Awesome information

OMG, This article is riddled with incorrect information. If someone followed this, they would destroy their car.

You mis-state the tolerance. It’s .150, NOT .0150

Then you instruct how to obtain “the third measurement”, when it’s actually the fourth.

Then you scramble B and C and claim that you need to add, when infact you need to subtract.