Springs? What’s so important about coil springs?

Quite a bit actually.

Coil springs tend to be one of the most important and most misunderstood components on a modified street or race car. There can be a lot of issues with springs. For instance, springs tend settle with age. Equally important, far too many hot rods operate with springs that have been improperly modified. The coils may have been cut by way of a torch or they may have been coil bound, for example.

Obviously, crude modifications to springs can do more harm than good. Case-in-point is a drag car with a stock style front suspension system. It’s common to install a set of race front coils, but sometimes the ride height is too tall. The quick “fix” is to cut the springs, but a month or two later, the car sags. Instead of buying correct springs, the next “fix” is to slip a set of black plastic spacer donuts on the spring to restore the ride height. However, this can stiffen the spring rate to the point where the car is seriously over-sprung.

Often, these well intentioned quick-fixes will mess up the the spring rate by shortening it. As a result, the ETs will change, and the car will develop quirky handling characteristics. The real fix is to use a quality spring that isn’t cut, even if it means having a set of springs custom wound.

Coil-overs aren’t exempt from this either.

When it comes to coil-overs, it’s just as easy to install springs with the wrong rate. Springs of all configurations are correctly picked by way of calculations based upon the geometry of the car, the corner weight of the car, the dimensions of the spring, and a series of component measurements. There is no magic one-size-fits-all solution when it comes to springs, and each car will require a different spring and spring rate.

Spring rate refers to the amount of weight needed to compress a spring one inch. For example, a 250 pound-per-inch spring with 250 pounds resting upon it will compress 1 inch. Three factors influence spring rate:

Wire Diameter: This effects rate since a greater wire diameter is stronger than a smaller diameter wire. When the wire diameter is increased, spring rate increases.

Mean Spring Diameter: This is the overall outside diameter of the spring, less one wire diameter. When mean diameter increases, the spring rate decreases.

Active Coils: Figuring out the number of active coils varies with the design of the spring. Count the total coils minus two for springs with both ends closed. For springs with one end closed and one end open, count the total coils minus one. As the number of active coils increases, the spring rate decreases.

Figuring Out The Spring Rate

In order to figure out spring rates, the first thing you should do is to determine the exact corner weights of your car while at race weight (including the driver weight, fuel, oil, etc.). Spring rates are determined by the amount the spring deflects versus the weight placed upon it. The actual suspension geometry can influence how much the spring deflects. You have to compensate for the geometry when determining the correct spring rate for your race car. According to pro chassis builder Jerry Bickel:

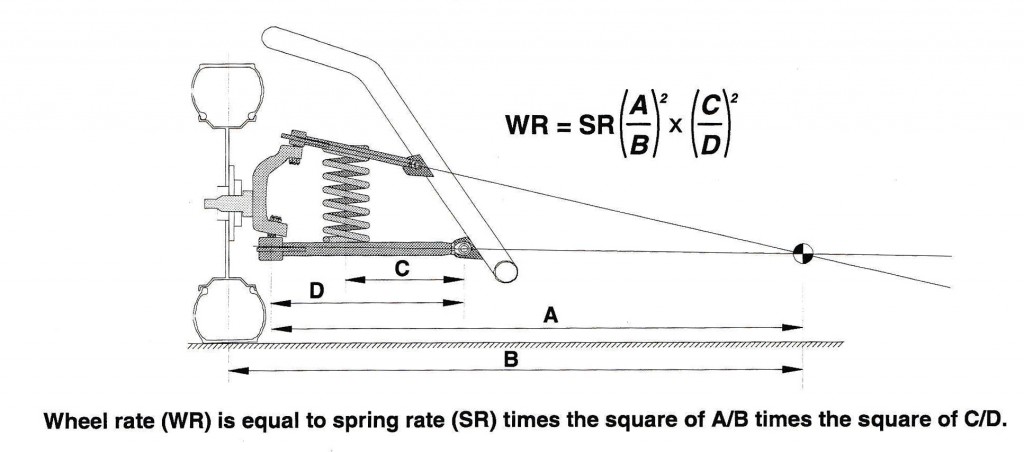

“When you buy front springs, the listed spring rate (lb./in.) will not be the same as the rate at the wheel. Front control arms are lever systems that alter the motion and applied forces between the coil springs and the wheels. The front wheels gain a mechanical advantage against the coil springs, so the wheel rate is always less than the spring rate.

Bickel has an easy-to-use formula for approximating front wheel rate (WR) versus spring rate (SR). Here’s a copy:

Jerry points out: “If the car has MacPherson struts, the top line should be drawn from the top strut mount at 90 degrees to the strut. Actual wheel rate is extremely difficult to calculate with accuracy. This is because the angles of suspension members change continuously though the normal range of travel and the front coil springs are not perpendicular with the pavement.

“Fortunately for us, front spring rates are not quite as critical in drag cars as they are for road race or stock cars. If your spring and wheel weights are within the correct range, little or no performance gain should be expected from changing them. Remember this rule when selecting spring rates:

“The farther the spring is from the tire, the lower the wheel rate will be. The closer the spring is to the tire, the higher the wheel rate will be.

“All of our Pro cars are equipped with MacPherson struts in front, with the springs very close to the tires. This is why the front spring rates we use are low compared to those used on cars with unequal length control arms.

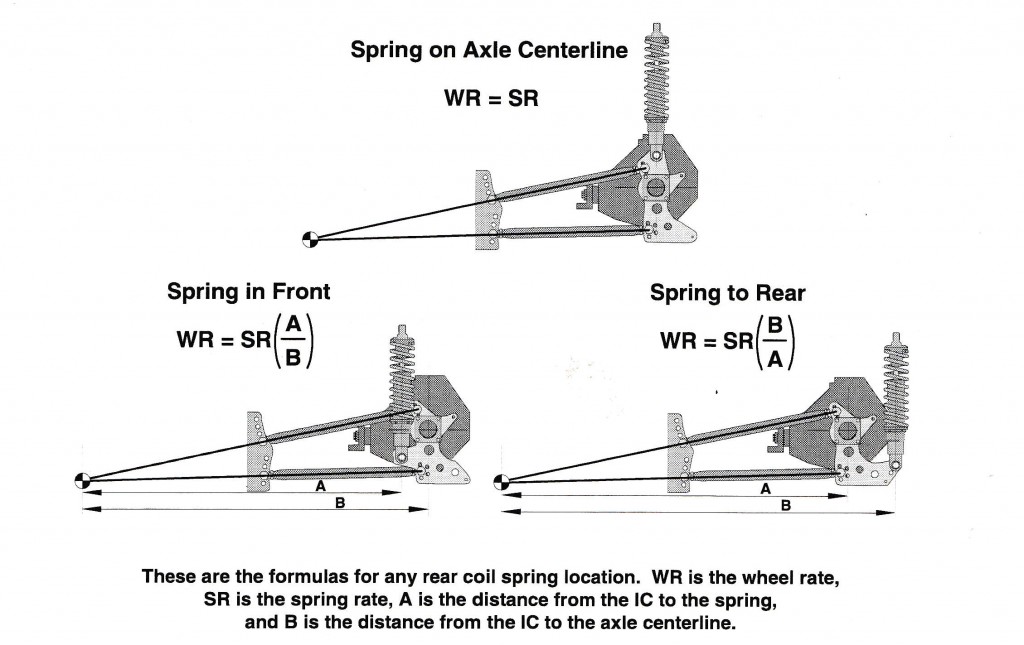

“Rear suspension members may also create leverage against the rear coil springs and affect wheel rate. This depends on the type of rear suspension system and the location of the coil-over-shocks. Depending on the builder, the rear coil springs may be located in front, on, or behind the rear axle centerline. These are the formulas to determine rear wheel rate for a drag race car:

“The same formula can be used for ladder bar suspension systems. Simply use the front pivot as the IC (instant center) reference point. I prefer to mount the coil-over shock behind the axle centerline. This keeps it from interfering with the four-link bars and lowers the top mounting location. (Below) is a handy front spring selection chart for drag race cars equipped with MacPherson struts. Remember that it’s only a rough guide for spring rates. The correct rate for your car may be somewhat higher or lower than those listed below.”

| Coil Spring Rate Calculator | ||

|---|---|---|

| Gross Vehicle Weight (lbs.) | Front Spring Rate (lb./in. approx.) | Rear Spring Rate (lb./in. approx.) |

| 2,000 | 185 | 85 |

| 2,350 | 200 | 95 |

| 2,500 | 215 | 120-140 |

| 3,000-3,500 | 250-350 | 150-200 |

Production Line Springs

As it turns out, the approximate spring rates provided by Jerry Bickel are very close to those required in many drag race cars without MacPherson strut front suspension systems. Moroso has long offered “trick” front coils for drag cars. These springs are designed with a small wire diameter and a long length that definitely promotes weight transfer. Moroso notes that many factors can influence front-end height of a racecar:

“Wheel offset is a major consideration. A front wheel offset to the outside will increase leverage of the lower A-arm against the coil spring and the nose of the car will be lower. Disc brake spacers will further affect the height. Adding or removing as little as 50 pounds can also make a big difference in front-end height. Take this into consideration when adding a fiberglass hood, aluminum heads, or when putting the battery in the trunk.”

The Moroso catalog lists a number of springs for common drag cars along with the rates of their springs. The front-end weight is the ultimate deciding factor when selecting springs. That’s why sharp racers check exact corner weights on their cars during setup.

In the end, it’s easy to see there are many different front suspension arrangements (modified MacPherson strut, short-long control arm, etc.), and there are considerable differences in geometry in each of them. Because of this, the spring rates can differ dramatically, even when overall front-end weights are similar.

Bottom line? Get the corner weights right and take the time to do the math.

Ref ““Rear suspension members may also create leverage against the rear coil springs and affect wheel rate. This depends on the type of rear suspension system and the location of the coil-over-shocks. Depending on the builder, the rear coil springs may be located in front, on, or behind the rear axle centerline. These are the formulas to determine rear wheel rate for a drag race car” oops no, it is a square of the ratio not just the ratio of the lengths toi get the effective wheel rate. Suggest a bit of maths first.