In our Head Start series, we’re giving you the dos and don’ts of choosing aftermarket cylinder heads.

Part One covered the don’ts — the most common mistakes people make when cylinder head shopping. Now we’re taking what we’ve learned from those mistakes and assembling some basic tips and guidelines to help you choose your cylinder heads wisely. Again, factors that play a role in cylinder head selection include:

- Engine displacement

- Type of vehicle

- Intended use

- Desired compression ratio

- Gear size

- Other performance modifications

While there is no one-size-fits-all solution for choosing cylinder heads (remember, cylinder heads are just part of a complete performance package), there are some basic rules of thumb you can follow.

The first question you must ask is:

Do I Really Need Aftermarket Cylinder Heads?

You may get different answers, depending on who you ask.

For example, Edelbrock design engineer Matt Gamble feels you can always benefit from a good set of aftermarket cylinder heads. “With the old factory small and big block Chevy heads, the tech we currently have wasn’t in place,” he said. “That’s why aftermarket heads can offer a big performance increase. The factory has stepped it up a bit, but you can still improve performance with aftermarket heads. The factory still has its hands tied with mass producing and things like emissions standards, where we can offer better features in our heads right out of the box.”

Norm Koval, a team leader in Summit Racing’s technical department, advises customers to look at aftermarket heads once they start shooting for that horse-per-cube or greater threshold.

“Mass production factory heads don’t have a great deal of uniformity in design and they’re not designed to flow and accommodate drastically larger power numbers,” he said. “And very few factory heads are able to handle stroker or large-cube, large-displacement upgrades.”

Gamble and Koval agree that getting a desired performance increase from a factory head is possible, but it may end up costing more in the long run.

“To get the factory head where it needs to be, you may be talking about a valve job, bowl blend, hardened seats, or other modifications,” Koval said. “You could wind up spending four or five hundred bucks or more on the factory head anyway.”

Once you’ve decided to go the aftermarket route for your cylinder heads, you’ll need to choose between cast iron or aluminum cylinder heads.

Aluminum vs. Cast Iron Cylinder Heads

Cast iron used to be the material of choice for cylinder heads.

“There was a stigma about the strength of aluminum, but that’s been addressed in the way aluminum heads are now produced,” Gamble said.

Gamble points to the weight savings of aluminum as a big reason aluminum heads have become so popular. The reduced weight offers obvious performance benefits but can also help out budget-minded enthusiasts. “The weight savings means they’re cheaper to ship,” Gamble said. “They’re also easier to machine and port than cast iron.”

The benefits of aluminum heads are:

- Lightweight design for drag racing or competition

- Superior heat dissipation to resist detonation

- Ability to handle moderate to high compression ratios

- Softer metal for easier machining

The main advantages of cast iron heads are:

- Excellent durability

- Lower price compare to many aluminum heads

- Low to moderate compression operation

- Heat retention means better combustion efficiency

Guidelines for Choosing Cylinder Heads

Once you’ve established a need for aftermarket cylinder heads and chosen the ideal material for your application, it’s time to zero in on your ideal option. Based on the vehicle’s intended use, Gamble provided tips and guidelines to get you moving in the right direction.

Street Performance Cylinder Heads

Bigger isn’t always better when it comes to port size. This is especially true for street applications, where throttle response and drivability are important.

“We’d recommend that you keep the intake ports on the smaller side to keep velocity high in the ports,” Gamble said. “While high-end power will suffer a bit, this will keep throttle response good, and drivability will be good as well.”

Gamble says a good set of street performance cylinder heads should excel in the 1,500-5,500 rpm range. Because they’re not typically operating at high rpm, street performance cylinder heads don’t need a really stiff valve spring. This helps to keep these heads economical compared to some higher-end cylinder heads which require stouter materials.

Depending on your vehicle and engine, some street performance options include:

Edelbrock E-Street Cylinder Heads

Edelbrock Performer RPM Cylinder Heads

Airflow Research Eliminator Street Heads

Summit Racing Aluminum Cylinder Heads

Street/Strip Cylinder Heads

Edelbrock Performer RPM cylinder heads feature larger intake runner for increased power throughout the rpm range. This makes them a good choice for street/strip applications.

Street/strip cylinder heads should perform up to at least 7,500 rpm, Gamble said.

“As you move up in the rpm range, port and valve size will increase,” he said.

Smaller intake ports often deliver better results for street performance and part-time race vehicles, and larger ports would likely cause the torque numbers to fall off. On the other hand, larger intake runners could benefit higher-revving or larger displacement engines. This becomes a balancing act, but Gamble says Edelbrock engineers strive to create the smallest port volume with the highest efficiency to achieve the desired operating rpm.

“A lot is tied to camshaft and rpm band, but people need to think about velocity through the port,” Gamble said.

Here are some other things to look for in good street/strip cylinder heads:

- Smaller-than-stock combustion chambers for increased compression (learn more about how combustion chamber size affects compression and critical clearances in Part One of our series)

- Stiffer springs to control valves at higher rpm

- Aluminum construction for lighter weight

- Upgraded rocker/rocker geometry

- Bigger valves for increased flow

- Increased wall thickness for future porting

Examples of excellent street/strip heads include:

Edelbrock Victor Jr. Cylinder Heads

Trick Flow PowerOval 280 Cylinder Heads for Big Chevy

Trick Flow PowerPort 290 Cylinder Heads for Big Ford

RHS Pro Action Cylinder Heads

Race/Competition Cylinder Heads

Competition cylinder heads should perform well at rpm levels in excess of 10,000 rpm.

Gamble says this is where big ports and big valves have their advantages. While you won’t get the crisp throttle response of a small-port/small-valve design, larger ports and valves flow better in the higher powerbands typical of race cars.

Trick Flow altered the valve angles from 23 degrees to 18 degrees on its Ultra 18 cylinder heads. The result is increased airflow, particularly at high rpm. You will need to use an 18-degree intake manifold, headers, and other components to complete the installation; however, the heads deliver pretty stout power gains to traditional small block heads.

You’ll also want to choose your combustion chambers wisely. Again, you can raise compression by using small chambers, and aftermarket head manufacturers will often include extra deck material to allow for milling. This allows you to effectively reduce combustion chamber volume and increase compression (read more on that here) on your own. Competition heads may also come with extra material for porting.

Do your homework on combustion chamber design as well. Manufacturers have spent considerable time reshaping combustion chambers to achieve maximum combustion. Companies like Edelbrock and Trick Flow use “heart-shaped” and Twisted Wedge chambers to alter the location of the valves and plugs and drastically change the flow and mixture motion of the incoming air/fuel charge.

A closer look at Trick Flow’s Twisted Wedge combustion chamber design. This setup unshrouds the intake valve and move the spark plug closer to the center of the chamber for better combustion.

Other characteristics of good competition cylinder heads include:

- Increased rigidity for added strength

- Lighter weight valvetrain components (titanium)

- Beefier valve springs to accommodate high rpm operation

- Upgraded rocker arm geometry

Examples of competition heads include:

Edelbrock Victor Series Cylinder Heads

Trick Flow Ultra 18 Cylinder Heads

Dart Pro 2 Aluminum Cylinder Heads for Big Chevy

The CNC Factor

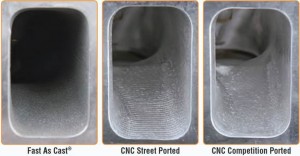

Some manufacturers offer CNC-ported versions of their cylinder heads. During the CNC porting process, the intake and exhaust runners are reworked to increase runner volumes and enhance the runner shapes. These heads are often marketed as flowing significantly better than as-cast heads. CNC porting also creates more uniform runner and chamber shapes, volumes, and valve locations from cylinder to cylinder. It also ensures the surface finish within ports and/or chambers is smooth and blemish-free. This all adds up to increased airflow and greater flow consistency along the intake path.

A comparison of Trick Flow’s different port surface finishes. The CNC competition ported offers the smooth intake path for the best possible airflow.

The amount of port work plays a role in the level of performance. For example, Edelbrock offers Victor ProPort CNC versions of its Victor Series heads. These heads are marketed as delivering maximum power. Trick Flow offers four different versions of its cylinders heads based on the amount CNC work done:

- Fast As Cast Standard: for grassroots racing and moderate performance builds

- Fast As Cast with CNC Chambers: same as Fast As Cast but with CNC-machined combustion chambers

- CNC Street Ported: CNC-machined ports and chambers with standard resolution surface finish

- CNC Competition Ported: CNC-machined ports and chambers with premium high-resolution surface finish for maximum flow

The downside to CNC porting and profiling is increased cost.

Again, the right cylinder heads are just part of the total engine package. The guidelines above can give you a good start in your search. Armed with detailed information about your specific vehicle and engine, the experts at Summit Racing, Trick Flow, and Edelbrock can help you cross the finish line in your quest for the perfect set of heads!

What is the benefits of longer rods pro’s and con’s and stroke. Jay Lee

Rod length has been an ongoing discussion for many years with varying opinions but, many engine builders agree that there are two main reasons to run a long rod. The first, is less side load on the piston. A short connecting ride (@bottom dead center) tends to try and push the piston into the side of the bore when it begins its travel back up the bore, this causes excess friction. The second reason is, the longer the rod, the longer it dwells at top dead center allowing the combustion process to build more pressure on the power stroke! This equates to a broader torque curve for the motor. Now, as stated already, opinions vary but if you want more info on this topic there are many reputable articles on the internet that will help further your knowledge. And we may address the topic ourselves here in the near future!

……and Big block Mopars ??….

[…] Head Start (Part 2), we’ll apply some of the information learned here to help you choose the right cylinder head […]

My ? is that I’m building a 489 cu in BBC with 6 .385 rods I don’t no weather purchase edelbrock performer RPM heads that will give about 9.8 cr or victor jr heads that have larger valves slightly bigger ports and a 106 chamber that will give 10.25 comp I no the lower cr will allow more total timing thus a better burn over the higher cr using less timing this is going in a 2500 ibs street car with a 4L80e and 390 gears it has a 232 238 @ .050 with .618 / 572 lift hyd roller cam and air gap 2X4 manifold Which head would you recommend

If you choose cheap aluminum cylinder heads there is always the problem of the valve seats falling out.