Quickly, what does a Porsche 911 and a 1961 Pontiac Tempest have in common?

If you said “they both have a transaxle,” then you probably read the headline of this article.

In most cases, a transaxle is a single unit that houses both the transmission and the axle assembly—simple to describe, but mechanically complex.

Think about it: A transaxle combines the function of the transmission and axle, along with other potential variables like a limited-slip differential and independent suspension.

Why do Vehicles Use Transaxles?

The prevalence of the transaxle design grew with the increase of front-wheel drive (FWD) cars. The setup eliminated the need for a driveshaft, and allowed the drive wheels to connect directly to the transmission. Its relatively compact design lent itself well to a small engine bay.

But transaxles have been around for a long time—and they aren’t unique to only front-engine, front-wheel drive vehicles either.

One of the most popular cars in history, the original Volkswagen Beetle, required a transaxle, thanks to its rear-engine, rear-wheel drive layout.

In fact, transaxles can be found in vehicles stretching back to the early days of the horseless carriage.

Is There a Performance Benefit to a Transaxle Configuration?

Several high performance cars have incorporated a transaxle setup (and we’re not just talking about rear-engined Porsches).

On a front-engined, rear-wheel drive car, the transmission can be moved to the rear and turned into a transmission/axle combo. In this type of configuration, the transaxle is linked to the engine via rigid torque tube.

…

A torque tube is not a driveshaft. Though they provide a similar purpose, a driveshaft is allowed to flex and adapt to angle changes between the transmission yoke and the rear axle pinion yoke. A torque tube is typically a rigid cylinder that’s bolted directly between the transmission and the engine. A spinning steel shaft inside the tube connects the engine crankshaft/flywheel to the input shaft of the transmission. Since the torque tube design doesn’t handle the amplified torque output from the transmission, the propeller shaft inside the torque tube can be far less robust than a driveshaft.

…

Locating the transmission rearward allows engineers to achieve better front/rear weight balance, ultimately resulting in better handling.

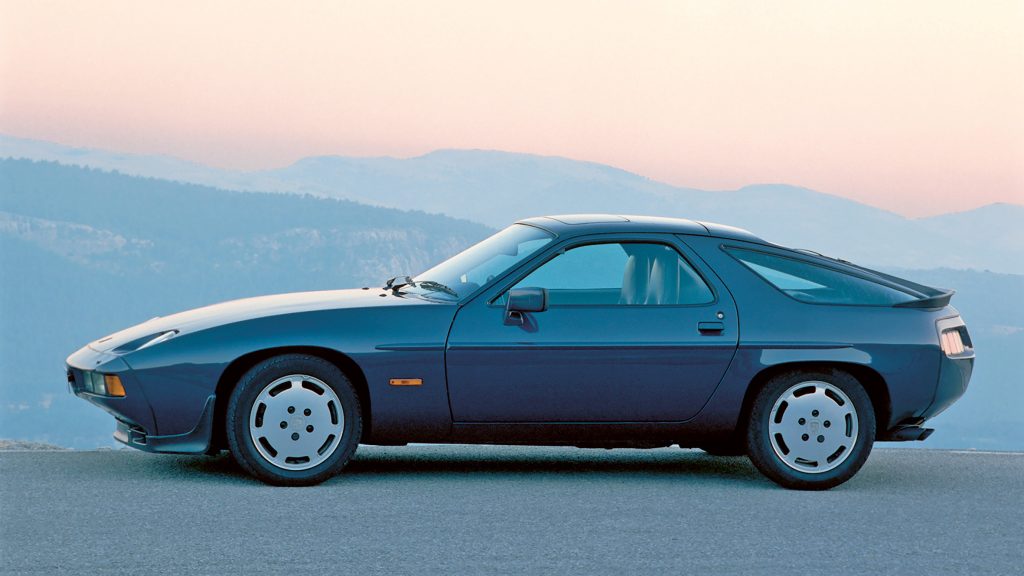

Corvettes have used a rear-mounted transmission* since the introduction of the C5 generation in 1997. Back in the mid-1970s, Porsche used a transaxle in the front-engine 924, and again in the 944 and 928.

Even Mercedes’ iconic gullwing SLS AMG has a rear-mounted transaxle.

*Pedantry Alert: Though it’s often referred to (even by GM literature) as a transaxle, technically speaking the unit actually consists of distinct transmission and differential units, bolted together.

…And the Tempest had One Too?

Yep.

General Motors went a little wacky in the 1960s when it gave the go-ahead to two unorthodox (for GM, at least) transaxle cars—the Corvair and the Tempest.

Unlike the Corvair’s rear-engine setup however, the Tempest kept the engine up front, and used the aforementioned torque tube to deliver power to the rear-mounted transaxle.

Among other innovations, the Pontiac Tempest’s clever “Rope Drive” featured a curved steel shaft inside the torque tube that was tuned to absorb the vibrations from the engine—and it worked. Unfortunately, we didn’t get to see the technology evolve, as the Tempest went to a conventional setup in 1964 with the engine and transmission in front, and the axle out back.

Can I Take My Transaxle Racing?

Sure. Local autocross courses are full of transaxle cars, be they front-wheel drive, Corvettes, or the occasional Porsche 924. Many sport-oriented FWD cars through history offered limited-slip differentials from the factory, including the Honda Civic Type R, Nissan SE-R, and Volkswagen GTI.

In fact, companies like GForce Engineering sell half-shaft upgrades for high-performance cars with transaxles—like the 1997+ Corvette.

Transaxle Care

Whether your transaxle vehicle is a daily driver or a weekend track toy, the key to both transaxle reliability and performance is regular maintenance. Check for fluid leaks. Replace gaskets and seals as necessary.

A typical fail point on a transaxle is the axle shafts themselves, typically at the CV joint. They’re usually covered by a plastic or rubber boot to prevent water and muck from entering the joint. Those boots should be inspected regularly.

Properly serviced, a transaxle is every bit as reliable as a traditional standalone transmission-and-axle setup.

[…] Corvair delivered its power to the rear wheels through a transaxle. A swing arm suspension was used in the back to absorb road bumps and […]

[…] Download Image More @ http://www.onallcylinders.com […]

Thanks for the explanation, I now understand how transaxle works

[…] De Tomaso Pantera was powered by a Ford Cleveland V8, and it used the same five-speed ZF transaxle as the […]

I found your article very informative and interesting

Hello Paul, I just found your article and hence the late reply, excellent explanation of the front engine transaxle set up, i am embarking on a project to do exactly this with a four cylinder Ford Engine and a Hewland transaxle, i have all the parts except the torque tube, do you know what companies I can contact to talk about a custom made torque tube for this installation ?

Thank you

Hey Simon, I’m not sure where you’re located, but you can ask around a competent machine/fab shop to modify an existing torque tube (vs. starting from scratch). I’ve heard of folks shortening stock torque tubes without much fuss for for retrofits, but I don’t know kind of build this is. Perhaps the folks at Hewland can help?