You’ve got questions, we’ve got answers. We work with the Summit Racing tech department to help you tackle your auto-related conundrums. In this week’s Mailbag, we’re calculating compression ratios and cylinder head volume on a modified 318 Chrysler small block.

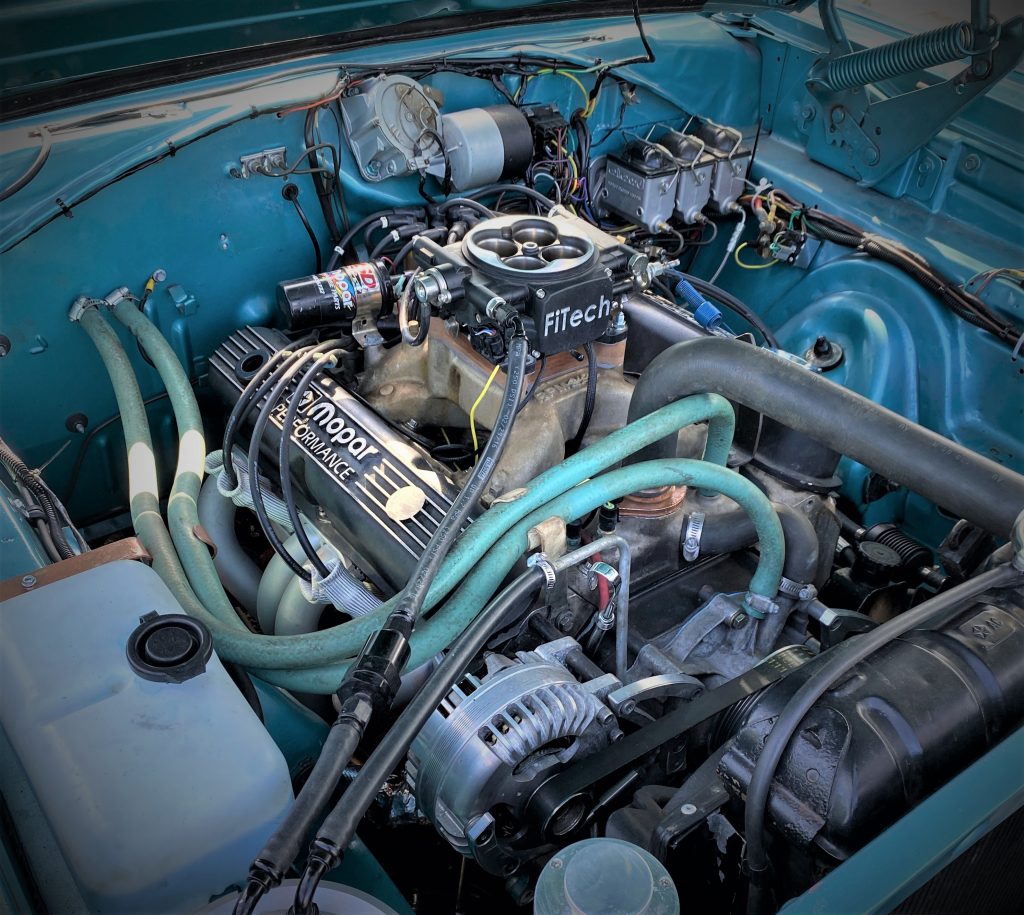

Q: I am planning to rebuild a Chrysler 318 engine. I want to keep the compression to around 9.0:1, but I want to replace the stock heads with Edelbrock Performer RPM aluminum heads. The stock heads have 57.3cc combustion chambers, while the Edelbrock heads have 65cc combustion chambers.

Someone told me that the Edelbrock heads will lower the compression to 8.5:1 with the stock 3.91-inch cylinder bores. Can I bore-out the cylinders to raise the compression up to 9.0:1? If so, how much should I overbore them? Is there a formula I can use to figure this out before I start machining?

A: Our calculations show the Edelbrock heads will lower the compression ratio more than you’re initially thinking—closer to 8.2:1 with the 65cc chambers.

To pick up the extra compression, you will have to bore the cylinders about 0.030-inch over and take about 0.033-inch off the head decks, or leave the bore stock and shave about 0.038-inch off the heads.

You can gain more compression with the head work than by overboring the cylinders. Since we don’t know how much piston-to-deck clearance you have, you will have to measure that clearance before doing any machine work.

Here is the formula for compression ratio.

Compression Ratio =

(Swept Cyl. Head Volume + Clearance Volume) ÷ Clearance Volume

Here is the formula for swept cylinder volume.

Swept Cylinder Volume =

Cylinder Radius x Cylinder Radius x Stroke x 3.145

To convert that to cubic centimeters, simply multiply your answer by 0.061

Here is the formula for clearance volume.

Clearance Volume =

Head CC – Piston CC + Deck CC + Gasket CC

Deck CC will be zero if the block is zero-decked (no material removed). Piston volume will be a negative number if the piston is dished, and a positive number if the piston is domed.

Feel compelled to add my 2 cents here. If HP is the ultimate goal, this machine work to raise compression is not good value for the dollar. Going from 8.2:1 to 9:1 will likely add 5 HP or less on a 318, according to readily available calculators. This – and a lot more – can be made up for by careful cam selection. And as this build will undoubtedly involve a cam change, net additional cost to make up that HP difference should be zero.

I really liked this post which is very beneficial for every person who wants to get some deep information about engines and about some other racing components. Thank you for sharing this post, Keep giving updates.

Thank you for sharing this piston which you have shared that how valves and pistons are important of people. Keep giving updates so that it will be useful for everyone.

I truly like to reading your post. Thank you so much for taking the time to share such nice information.

Amazing post, I am happy to read your blog, Thanks for telling us about “Formula for a Mpoar 318 Engine Build”. Your post will be helpful for all. Your post is easy to read and easy to understand. Keep sharing more and more post with us.

I quote you ” Deck CC will be zero if the block is zero-decked (no material removed). Piston volume will be a negative number if the piston is dished, and a positive number if the piston is domed.” Is this correct or vice versa ?

I must agree with George Scott. A lot of

machine-work on a 318 isn’t worth the

money. What about new pistons with the

Edelbrock heads? Or you could look for one of the

360 crate-motors that may be available.

Or just upgrade the 318 with an aluminum

manifold and 4V carb. Add mild cam and

small-tube headers.