A check valve is a fundamental component of a compressed air system—whether that system is intended for inflating tires, powering air tools, or driving a set of air horns.

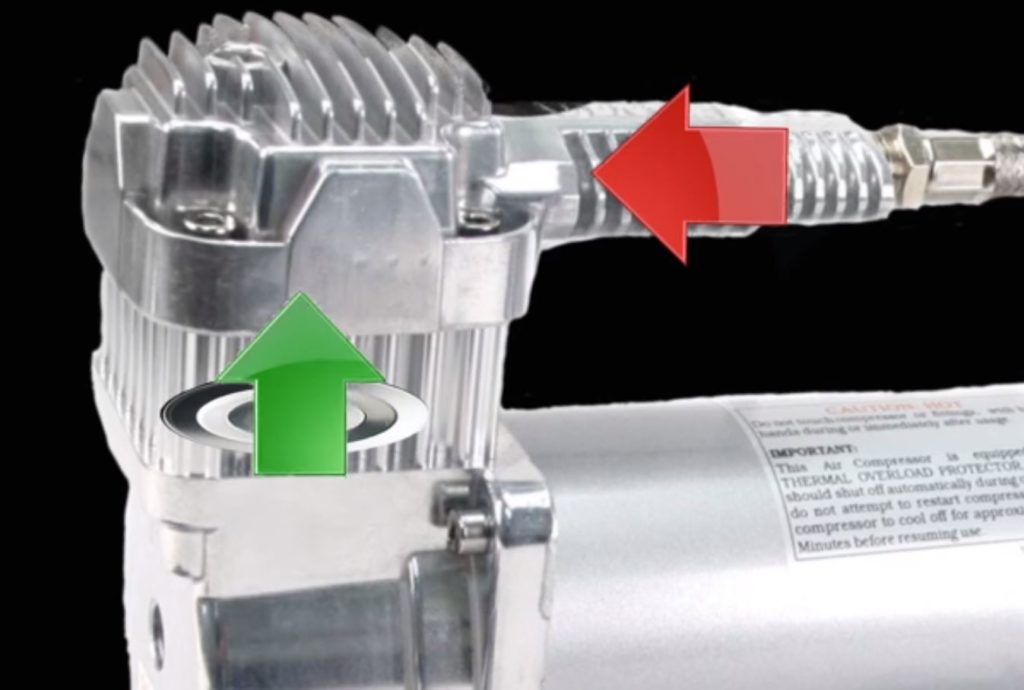

The purpose of a check valve in an air compressor system is to control the flow of the pressurized air to ensure that it only moves in one direction.

By preventing air from moving against its intended direction, you’ll prolong the life of your air compressor while maximizing the efficiency of your compressed air system.

You can often find check valves in fuel and hydraulic (e.g. brake) systems too. They serve a similar purpose, preventing the flow of fluid in an opposite, undesired direction.

As part of its “Basics” series, the fine folks over at Kleinn Air Horns made this two-minute video to show you exactly why a check valve is critical to the performance of your compressed air system.

The video also covers how to install a check valve into your system properly. It demonstrates the importance of using proper thread sealant, and how critical it is to make sure you don’t over-tighten any fittings to avoid damaging the valve or related parts.

Comments