(Image/Wayne Scraba)

In part one of this two-part segment, we dug into Holley Performance Product’s top-of-the-heap Dominator EFI system.

If you recall, we noted how sophisticated this system is and how user friendly Holley has made it. With that initial look, we looked at everything from self-learning to the base maps Holley provides.

This time around, we’ll investigate further, examining everything from programmable inputs to built-in data logging. In the accompanying photos, we’ll dig into some of the wiring and hardware. This is one serious EFI system, and Summit Racing has them in stock, ready to go. For more, check out the following:

Programmable Input/Outputs Plus Pin Mapping

Holley equips the Dominator ECU with a whopping 50 programmable input and 40 output pins.

These programmable inputs can be configured for 12V, Ground, Digital Speed, IPU Speed, 5V, 20V, and Thermistor types.

On the other hand, the outputs can be configured as +12V, Ground, or +12V and Ground Pulse Width Modulated (PWM) formats. Holley advises that these pins can be configured to perform jobs such as sense transbrake engagement (along with disengagement to release the two step), turn on a low oil pressure light, or even create a comprehensive data acquisition system (more on this later).

By the way, several of the pins are pre-configured for use as fuel pump triggers, electric fan controls, A/C override, and IAC (Idle Air Control) kick.

Ignition Control

In order to set up the ignition on the Holley Dominator, the first step is to fill out the “Ignition Parameters” section in the menu.

In this case, the ignition type is designated. The menu also allows you to input the firing order, input the knock sensor parameters (if they’re used), input parameters for cranking timing, and input parameters for rev limiters.

In the case of rev limiters, Holley’s Dominator EFI system is equipped with three of them and each has with four cutout options. Included is a primary rev limiter along with two limiters that can be set up based upon a programmable input signal (for example, a burnout limiter, or a launch limiter).

The four limiting types include “Fuel Only,” which performs a “hard cut” of fuel flow when the RPM limit is reached.

Holley advises that a “Hard Cut” occurs when fuel flow is stopped to all cylinders until the main low RPM setting is met.

There’s also a “Spark Only” limiter option where a hard cut of ignition to all cylinders occurs when the high RPM is hit and continues until the low RPM setting is met.

The Fuel and Spark format is where a hard cut of ignition and fuel flow occurs when the high RPM limit is hit. The Soft type uses “soft cut” of ignition from individual cylinders as needed to bring the engine back to the low RPM limit (similar to a MSD Soft Touch rev control).

Holley tells us they have a fail-safe included in the system: If the high RPM limit is reached despite the soft cut, a hard cut will be implemented (using the main over-rev limiter). Similar to the base fuel map, the spark map can be viewed and adjusted in a table or a graph form.

Similar to the fuel map, you can make adjustments as you wish to the main table.

The Dominator system is designed to function with 4, 6, 8 and 10 cylinder four stroke engines.

Ignition is a simple plug and play with GM LS engines (non-VVT), GM HEI, Ford TFI, along with magnetic, hall effect triggers and coil negative systems (for non-timing controlled applications).

There are also custom settings that can be configured to allow you to use other applications too. This means you can continue to use an existing ignition setup (for example a MSD 7AL-2 box with a crank trigger). The Holley EFI easily integrates with it.

Should you have a distributorless (DIS) system, Holley includes twelve channel Distributorless Ignition (DIS) outputs. The Dominator is capable of directly driving “Smart” ignition coils or Holley DIS coils. It will also drive 2 wire coils with the addition this Holley high current coil driver module.

Transmission Control

We touched on this previously, but the Dominator can control GM’s 4L60E as well as the big 4L80E electronic control transmissions. There is no need for a separate control box and with the Dominator you can input things such as maximum RPM, maximum vehicle speed, enable paddle shifters, enable an auto/manual shift mode and even enable a speedometer output.

Included is an easy-to-use table configuration interface that sets up the part-throttle shift scale, line pressure scale, accumulator pressure scale and the torque converter lockup scale. Holley notes that other electronically controlled transmission combinations are in the works and will be made available for the Dominator ECU soon.

Sensors & More

If you have an engine that includes a drive-by-wire throttle system, the Dominator can control it.

Even better, Holley’s Dominator ECU is capable of controlling a pair of drive-by-wire throttle bodies (that brings up some interesting combinations to think about).

The Dominator system is compatible with a wide range of OEM drive-by-wire throttle bodies, including GM, Ford, Chrysler, Nissan as well as aftermarket units designed for those applications. With drive-by-wire, you can even set up the way the EFI responds to the pedal inputs (basically throttle position versus pedal position).

For example if you prefer a softer pedal (such as a typical late model passenger car), then Holley’s system can accommodate those parameters. Should you desire a sensitive racecar feel to the pedal, you can get that too.

When Holley engineered its EFI systems, it made sure they would function using common OEM sensors. Not only that, the Dominator can also accommodate aftermarket sensors by way of a custom sensor calibration input.

The Dominator has two-channel knock control sensor inputs for one- or two-wire knock sensors. And it also includes integrated dual channel wide band oxygen sensor controls.

This allows the management system to monitor both engine banks (by way of NTK or Bosch sensors). If you have a nitrous or otherwise boosted combination, you can appreciate how valuable this feature is. More on nitrous and boosted applications later.

Holley’s Dominator can be setup to accommodate your choice of Speed Density, Alpha-N, Alpha-N Combination, and VE fueling strategies.

Holley advises this gives you the option to select from a variety of load sensing strategies in order to meet the engine requirements or to meet your personal tuning preferences. The system includes twelve sequentially driven 8:2 peak and hold injector drivers, capable of driving up to 24 low or high impedance injectors as a standard feature. Because of this you can program multiple staged injectors in your combination.

The Dominator ECU also allows for individual cylinder fuel and spark control. All of this really means you have the power to unlock the full potential of the engine combination. And for specific applications (for example, alcohol-fueled engines), Holley has recently released a programmable eight-channel injector driver module. This is for applications that require a large set of secondary injectors. This module features easily programmable injector current curves, injector test fire mode, two datalogger outputs, multiple peak and hold current settings, and more.

The Dominator ECU is designed with dedicated fuel and oil pressure inputs (along with an extensive range of other inputs and outputs that allow for limitless combination of options). Holley doesn’t “hard-code” system inputs and outputs on the Dominator. What this means is you make the choices—including what you name an input or output.

The additional inputs are as follows:

- 13 “Multi-Inputs”– Can be configured as a 0-5V sensor input, 0-20v sensor input, thermistor temperature input, or high or low voltage input

- 30 0-5V Sensor Inputs – Configures any 0-5V sensor as well as some can be used as switched high or low inputs

- 4 Speed Inputs – Can be configured as a digital (square wave) input or an inductive input

- 20 12v PWM Outputs – Can be configured as PWM or switched 12V outputs. Rated at 2A maximum

- 16 Ground PWM Outputs – Can be configured as PWM or switched ground outputs. Rated at 2A maximum

Holley notes:

“All inputs and outputs are programmed using innovative new ‘Pin Mapping’ strategy that allows inputs and outputs to be pinned as desired by the user, allowing for inputs and outputs to not be ‘wasted’ by non-used dedicated functions.”

“The system is configurable for: dual cooling fans (including brushless fans that require PWM signal), dual fuel pumps, AC inputs, basic TCC lockup, and multiple timing retard inputs. There are also user programmable caution and warning outputs for all sensors.”

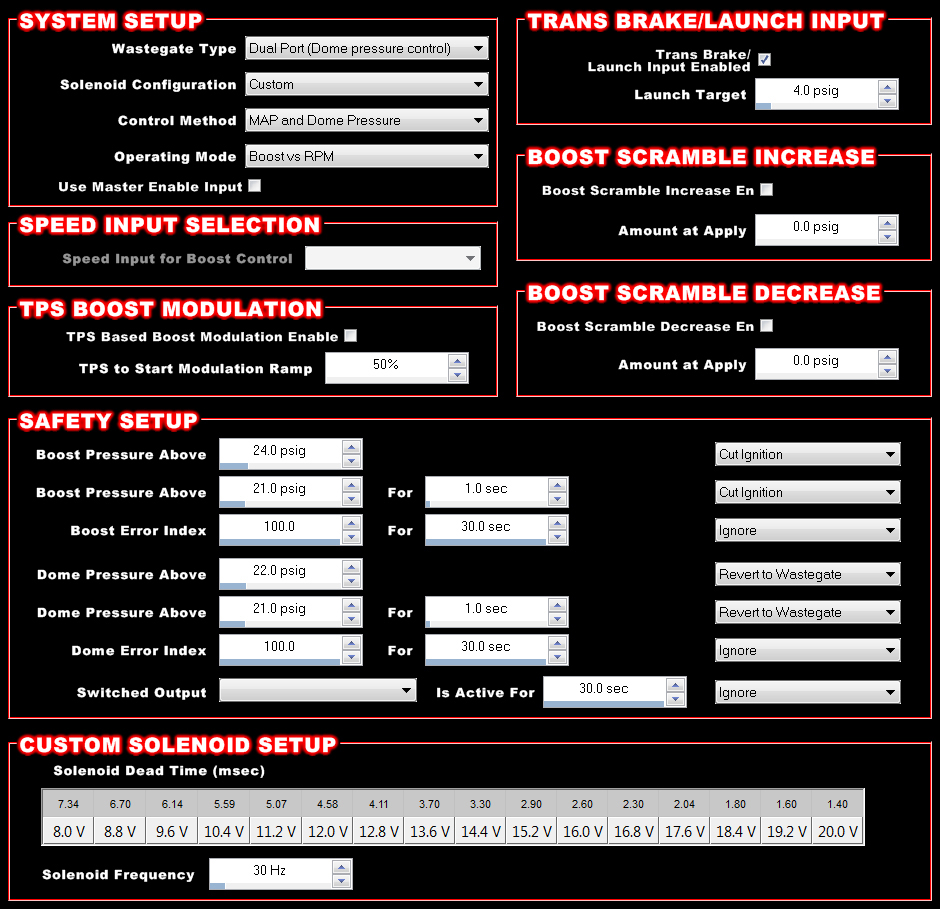

Turbocharger Boost Control

The integral boost control included in the Dominator has capabilities that completely eliminate the need for a separate boost control device. Holley advises that the Boost Control can be configured to control boost based upon time, gear, speed, and manual inputs (gear based boost control is actually configurable by way of several different methods).

When configuring the system, you’ll need to determine the type of wastegate you are using (single-port or a dual-port style wastegate). You chose the solenoid configuration, select the control method and determine the operating mode.

The Dominator provides a number of control strategies, which allow the control of the wastegate dome pressure or control of the actual manifold (boost) pressure.

Holley’s Boost Builder system includes a launch boost target, boost scramble, along with a rather extensive boost safety system to protect your engine from any component meltdowns. That’s not quite the end either. With the Dominator Boost Builder, you have the ability to build boost on the starting line by altering ignition timing, fueling, or—get this—include nitrous oxide activation (yikes!).

Nitrous Oxide Control

Speaking of nitrous: the Dominator includes a sophisticated nitrous control system built right in (once again, no need for a separate controller).

The integral Dominator controller can be configured for wet or dry systems, and it can also be configured for progressive or non-progressive systems (with up to eight stages).

Within the “Nitrous Parameters” software, you actually enable each stage, along with the TPS trigger point, as well as lean and rich cutoff AFRs. In each of the stage setup pages are controls for nitrous type (wet/dry, progressive, non-progressive) RPM trigger plus cut off, delay, closed loop settings, and progressive control.

The design of the progressive control is such that it can be time or RPM based. The time based control can be used to reduce power early in a ¼-mile pass, and as you can well imagine, that’s extremely useful for a tire limited application or if you’re big into no prep racing and the track is sketchy a few seconds out.

Each of the nitrous stages includes a separate timing retard control that can be sequenced with progressive nitrous ramps to maintain optimum timing. Needless to say, in an EFI application, the use of a dry nitrous system is often preferred because of the more precise fuel compensation that a nitrous nozzle can’t achieve. The Dominator will compensate with extra fuel to the injectors to maintain the correct AFR (and by the way the Dominator will look after this even if you forgot to program it that way).

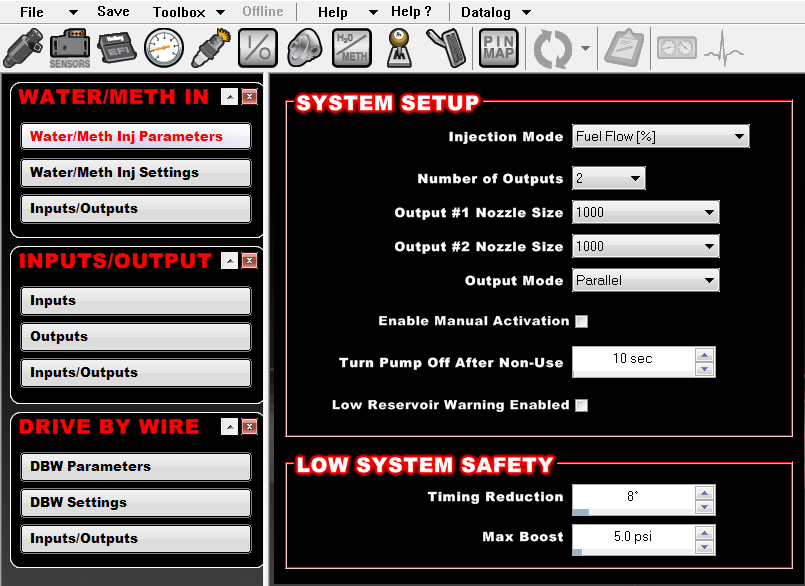

Integrated Water/Methanol Injection Control

Holley’s Dominator system includes a water/methanol injection control within the ECU.

Holley tells us that “the sole purpose of water injection is to cool the incoming air/fuel mixture while the purpose of methanol is to add an equal part of a combustible material. The Dominator EFI system is unique in that you can program what percentage of water/methanol flow you desire, as a function of fuel injector flow. This allows for precise tuning based upon engine RPM and load and for the engine not to be over- or under-injected.”

With this setup, you must use Holley Water/Meth solenoids and nozzles. That’s because they are flow-characterized for the system.

The Dominator system allows for two nozzles to be controlled (nozzles available from 400 to 1000 cc/minute). Additionally, the Dominator provides complete control of the water/meth pump activation along with several low system safety features (for example, it can trigger a low reservoir warning lamp).

Traction Control

The Dominator is engineered so that it can work in conjunction with Traction Control (this requires Holley’s latest “Active Speed Management” module).

From Holley:

“Active Speed Management is a time based traction control system based on engine speed and/or driveshaft speed. The system allows you to import Racepak driveshaft curve and RPM data directly into your ECU. When you import crankshaft or driveshaft curves from previous passes, the curve will automatically populate on the graph.”

Essentially, by monitoring the average rate of acceleration of the driveline, the active speed management system reacts to any sudden increases in that rate.

Holley also notes the system does require you include a driveline speed sensor, be it wheel or driveshaft speed.

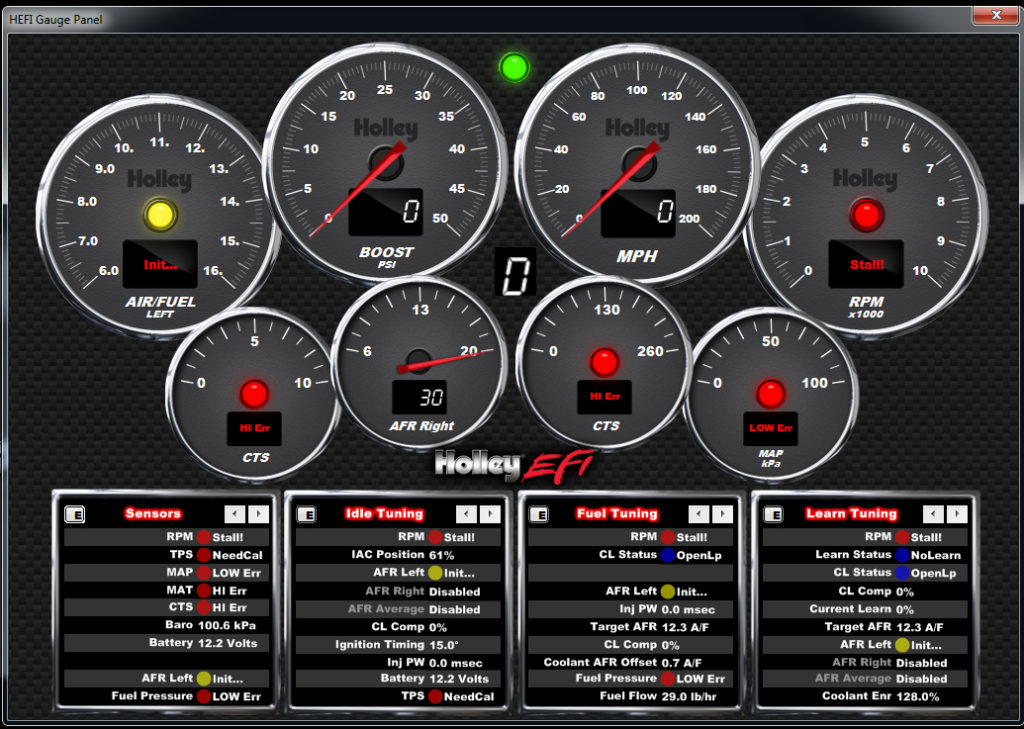

Data Logging

The Data Logging package included within the Dominator ECU surveys all sensors at a rate of 100 samples per second.

Standard data log items included in the Dominator are TPS, MAP, CTS, MAT, A/F, Target A/F, Closed Loop Compensation, Closed Loop Status, Barometer, Learn Status, Fuel Pressure, Oil Pressure, Fuel Flow, Injector Pulse Width, Injector Duty Cycle, Ignition Timing, Nitrous Ramps, and Boost Ramps.

Holley states:

“Data Logging is extremely useful for not only reviewing race history, but for trouble shooting as well. Holley EFI can perform both PC and internal logging (when a laptop can’t be present). The number of items being logged as well as the rate of logging can be adjusted in the Datalog dropdown.”

“Logging can be triggered by an engine start, immediately with an adjustable max on time, or triggered. It can be triggered by any input including RPM, TPS, nitrous activation, oil pressure reading, or a toggle switch just to name a few. Holley EFI has a data overlay feature, which allows for a data log to be traced on any screen in the tuning software.”

“The internal logger has a huge 2GB of memory, and samples all channels up to 100 samples per second. This high sampling rate can be helpful when trying to diagnose a malfunctioning sensor. Each view can be saved separately for quick reference.”

…

And there you have it. When you dig into the Dominator, you find that the entire system is over-the-top comprehensive. Equally important, the system has been designed from the very beginning to be user friendly. What’s more, Holley regularly provides free upgrades (users can simply download the upgrades from the Holley Website). State-of-today’s-art? No question and it’s all available right here, right now at Summit Racing.

…

This photo shows several of the harness assemblies used for the Dominator EFI system. Harnesses can be ordered assembled or partially assembled (on the left is the trick tool Holley offers to complete the harness assembly). Obviously when you assemble the harnesses yourself, it allows it to be custom fit to your vehicle. (Image/Wayne Scraba)

…

With the partially assembled harness kits, Holley supplies the necessary terminals and connectors. (Image/Wayne Scraba)

…

Each terminal connector is individually bagged and clearly labeled. The beauty of a partially assembled harness is you have the freedom to route it where you want it. (Image/Wayne Scraba)

…

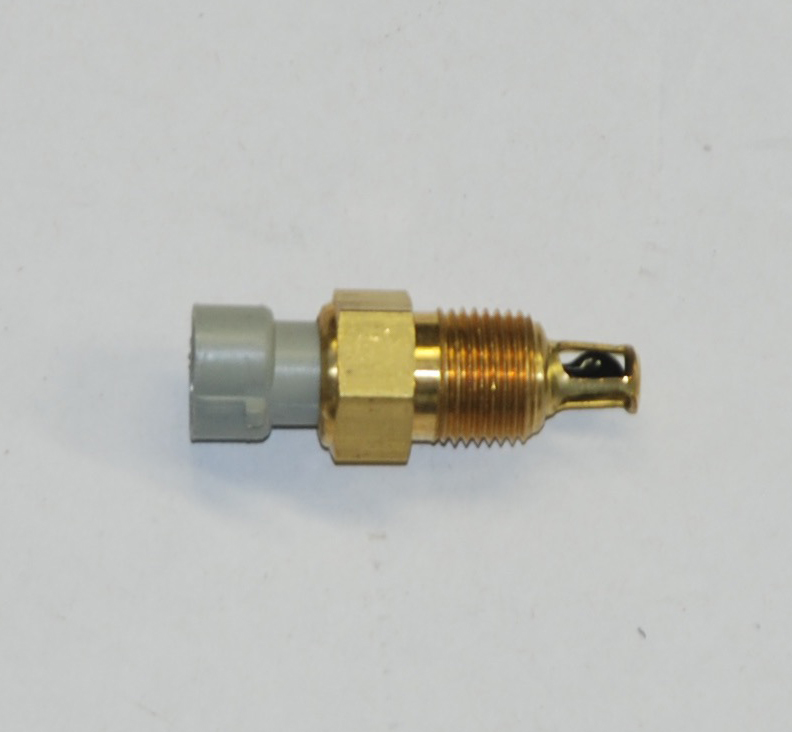

Holley offers all of the sensors required for EFI operation.

(Image/Wayne Scraba)

…

As noted in the text, all sensors are easily replaceable. You can find replacement parts at Summit Racing. (Image/Wayne Scraba)

…

The kit includes an oxygen sensor. (Image/Wayne Scraba)

…

Remember when we said the software was incredibly user friendly? Here’s a shot of the screen for the Dominator Boost Setup. As pointed out in the text, there all sorts of options you can select from. (Image/Holley)

…

On a similar note, this is a screen shot of the water/meth injection setup. Basically, it provides for complete setup along with a built-in safety valve. (Image/Holley)

…

This is another good example look at how Holley’s EFI software has made things simple for the end user. Included in the software is a gauge panel display for your computer. It allows you click on a specific gauge and configure it for your application. (Image/Holley)

[…] Note: This is Part One of a two-part article on Holley’s Dominator EFI Management System. Click here if you’d like to skip to Part Two. […]