(Image/Jeff Smith)

I’m currently checking the gaps on a new set of first and second rings. I’m not building an all-out drag race motor, but have plans to be a weekend warrior. I mostly will be on the street and all the information I’m reading on ring gaps have me concerned. The new rings out the box have a gap of 0.026-inch top and second. The ring manufacturer suggests the top ring to be 0.020-inch and the second ring 0.004- to 0.008-inch larger. So out-of-the-box the gap is larger than recommended? Do I leave the top ring at 0.026-inch and file the second to 0.030-inch or leave them both the same at .026-inch? My bore is 4.440. — W.B.

…

Jeff Smith: Production replacement rings are generally set conservatively to ensure that they will not butt during normal street use.

Since you are using standard replacement rings, this is a normal end gap for your top and second rings. This is also why ring manufacturers offer 0.005-inch oversize rings to allow the engine builder to custom set his own ring end gap.

We’ve included a ring end gap chart provided by JE Pistons to illustrate what this company recommends for various end gaps.

JE Pistons Ring End Gap Recommendations

| Top Ring | 2nd Ring | Oil Ring Rails | |

|---|---|---|---|

| Application | Minimum Gap Per Inch of Bore | Min. Gap | |

| High-Perf. Street-Strip | Bore x 0.0045" | Bore x 0.0050" | Min. 0.015" |

| Street, Moderate Turbo/Nitrous | Bore x 0.0050" | Bore x 0.0055" | Min. 0.015" |

| Late Model Stock Car | Bore x 0.0050" | Bore x 0.0053" | Min. 0.015" |

| Circle Track/Drag | Bore x 0.0055" | Bore x 0.0057" | Min. 0.015" |

| Nitrous Race Only | Bore x 0.0070" | Bore x 0.0070" | Min. 0.015" |

| Blown Race Only | Bore x 0.0060" | Bore x 0.0063" | Min. 0.015" |

For your engine, you have correctly calculated what the ring end gap should be for your 4.44-inch bore engine. Looking at the chart, JE recommends a minimum end gap for a normally aspirated street engine on gasoline at 0.0045-inch per inch of bore size. Multiplying this 0.0045 times 4.440-inch bore generates 0.0198 which rounds off to 0.020-inch.

Your end gap of 0.026-inch is substantially greater than this recommendation but since you said this is a mild street engine, that’s an acceptable top end gap. Looking at this as a glass-half-full opportunity—you could easily run a mild 150- to 200-horsepower nitrous shot on this engine and you’d still have plenty of top end gap clearance!

To further this point, I spoke with Ed Law of Total Seal ring company and he said that if the spec is 0.020-inch and you overshoot a couple of rings by even 0.002-inch (making the gap 0.022-inch for example) that this would be very difficult to evaluate once the engine has run. So by extension, a slightly large gap is likely not an issue for your application.

As for your question about the second end gap, using the recommended 0.005-inch times 4.440-inch bore generates a 0.022-inch recommended gap. Your 0.026-inch gap is okay. The idea is to run a slightly larger gap for the second ring to prevent a pressure buildup between the top and second ring. Since your gap is already larger than the JE recommendation, this is not ideal, but acceptable

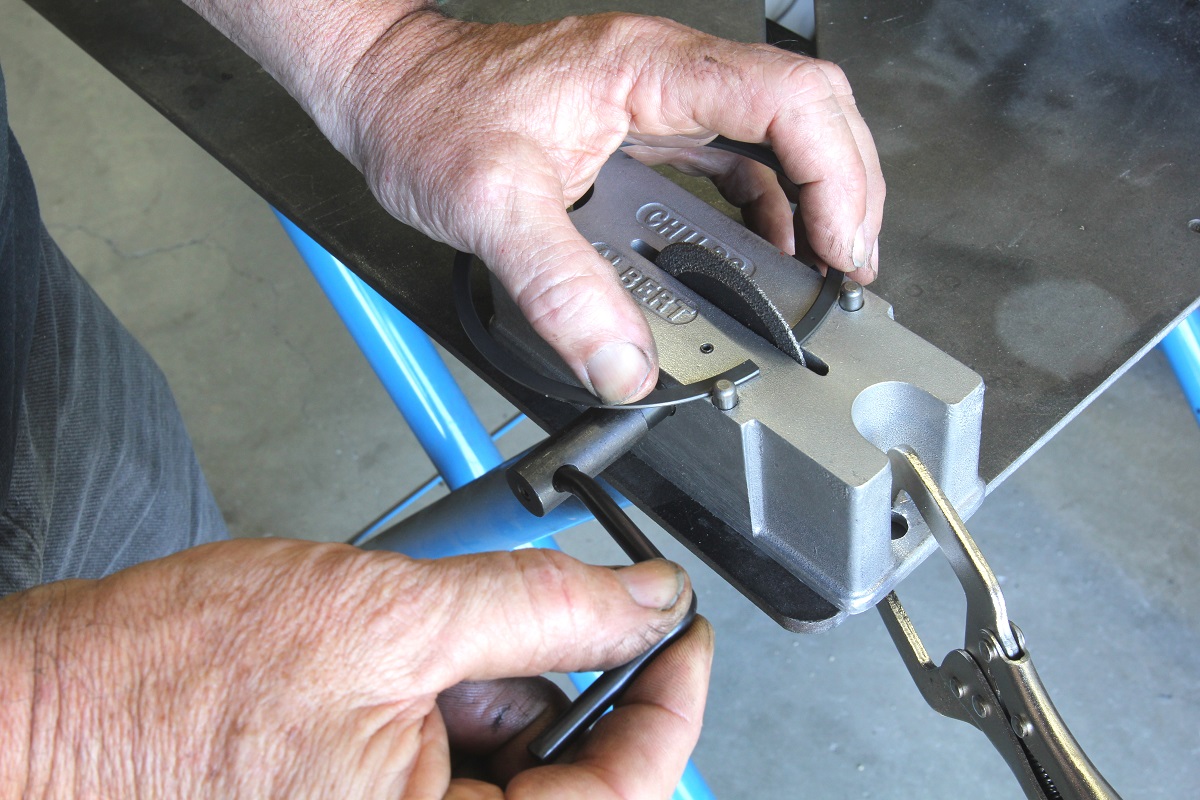

Setting custom ring end gaps can be accomplished easily enough. For years, we used a Childs & Albert manual ring filer that did a great job. Summit offers several manual ring filers that are very affordable.

If we were building a competition engine, then the suggestion would be to obtain a set of 0.005-inch oversize rings and set the proper clearance. But for your engine, the wider clearances will be acceptable. It’s possible the engine may experience slightly more cylinder pressure leakage past this larger gap, but it probably won’t greatly affect ultimate power. So assemble your engine with the end gaps you have and enjoy your new engine!

Due to the different expansion rates of the material and construction of pistons how does this affect ring end gap?

This calculation is amazingly correct. And thanks for calculating this for engines. This calculation will help other people to maintain at https://topcvwritersuk.com/resumesplanet-review/ and repair their engines. Keep doing better for humanity. Thanks for sharing this.

I built a 289 Ford .030 over bore, it has 11.1 comp. Forged piston light weight, I had a circle track engine builder help me we didn’t bushing the rods, just free floated them in the rods, he said that he did alot them that way, the rings are all set at .012 gap , my question is from charts I’ve read its not enough, but he said its not, Its a street engine has a set of Windsor Senior heads and a Comp 294S cam and a 650 holler I’m bout to fire up do I have a problem with ring clearance?

I work for a company that specializes in selling piston rings for all cars new/old, I am currently using an old perfect circle ring gauge to measure all our ring

We looking for a new piston ring measuring gauge but are not able to find one, any suggestions?

Hello, most ring gauges we’ve seen are custom machined items and not many have collections of these outside the major manufacturers.