I have a 1972 Jeep CJ-5 with a 3.73:1 gear and 33-inch M/T tires. The engine is an AMC 360 rebuilt with 8.75:1 compression, stock heads, and a COMP Thumper cam with 226/241 at 0.050-inch tappet lift with 0.491/0.476-inch lift and a 107 degree lobe separation angle (LSA). The intake is an Edelbrock Performer with an Edelbrock 1406 600 cfm carb. The ignition is MSD set at 14 degrees initial with 36 degrees total. It also has Edelbrock headers and a wideband AFR gauge with dual exhaust and Flowmaster mufflers.

My problem is my AFR gauge goes fat (and the Jeep feels fat as soon as I dip my toe into the main jets, and wide-open throttle (WOT) never goes leaner than 10.5:1 to 11.5:1. It only improves slightly as air conditions improve, but not much. Using my Edelbrock Tuning manual, I’ve gone to the #10 setting on the model 1406 Calibration reference chart which is 2 stages leaner. I’ve even leaned the secondary jets to a .089, and it still goes fat. I am thinking it has something to do with engine vacuum because Thumpers are known to have lower vacuum and therefore I’m thinking the signal to the carb is making the secondaries open too fast.

I want to fix this and have thrown multiple set-ups, springs, carb cleanouts and my thinking is there’s no way I should be running this rich. My plugs are hard to read, timing looks good, heat range seems fine, porcelain looks okay. I have it idle at 800 rpm, the accelerator pump is fine, I run ported vacuum advance. At idle my gauge is showing 9 “Hg. I know my cam is a little big even though I got the smallest Thumper. Is the cam too big? Is it dumping fuel because the vacuum signal disappears too soon? My cruise circuit is great around 14:1. It’s as soon as I get on it or go up a hill, it starts getting into the power and instantly runs fat.

Lastly, thank you. It is mostly because of you and a few other writers in the industry, and me reading your magazines for many years that I know as much as I do now. — M.A.

…

Jeff Smith: I had to work on this one for a while before coming to a final conclusion. The difficulty with diagnosing these kinds of problem is that we have to rely on written descriptions as opposed to personally witnessing the issues. On the plus side, this reader has given us plenty of data which is very helpful. There are some situations here that deserve addressing.

First, it seems odd you can generate a 14:1 AFR at cruise and yet go extremely fat at WOT. I don’t think it has anything to do with the rate of secondary opening. I just ran the numbers and your secondary jet change is 12-percent leaner than stock. That is a major change in jetting. On a Holley, that would be roughly equivalent to four jet sizes, which indicates that something is off.

As a first suggestion, I would look at the fuel pressure. Edelbrock carburetors are sensitive to high fuel pressure — perhaps at WOT the pressure is excessive and making the engine run rich.

Upon further thought, the above scenario is unlikely. Instead, it could be that you are suffering from an errant oxygen sensor. I’ve experienced an O2 sensor that would do the same thing — report the engine was 10.5:1 AFR at WOT, yet it was close to correct the rest of the time at idle and part-throttle. Believing the O2 sensor, at the drag strip I leaned the jetting and then the engine lost power and the car slowed dramatically.

I went richer than where I started and the car responded quicker — even though the O2 sensor was telling me the engine was running at 10.5:1 AFR. It’s possible your O2 sensor is incorrect. On my car I had two different sensors (one in each bank) and both read incorrect at WOT. I don’t have an explanation for why. This occurred even after I re-calibrated one of the sensors.

I suggest this: Put the Jeep in a gear and record the time it takes to accelerate at WOT from 2,500 to 5,000 rpm (or any rpm range you are comfortable with).

Do this in a safe place and have a friend run the stopwatch. Perform this test at least three times and average the numbers.

Once that is completed, richen the carb back to the stock secondary jetting and perform the acceleration test again. That is your ultimate evaluation — my guess is that at WOT the engine is too lean even though the O2 sensor reports the opposite.

The best way to perform the timed run would be to keep the transmission in second or third gear. If it’s an automatic, run the test by manually holding the trans in gear where it won’t downshift. Try a gear that will allow acceleration from 3,000 to 5,000, for example.

Many years ago, I was trying to tune the secondary jetting on a Q-jet on a small-block and it appeared by reading the plugs that the engine was too lean. So I richened the jetting several times and the car slowed down each time based on my mph readings. My knowledgeable Q-jet buddy insisted I was going the wrong way.

After wasting much time and being thoroughly frustrated, it turned out he was right because he knew approximately where the jetting should be and knew my jetting was too rich. The lesson here was to watch the engine’s performance and use that to dictate the jetting. In your case, there is an instruments error.

All of this sounds simple and incredibly basic — but you would be amazed at how often people are led astray by false information.

While I don’t have the time to trade emails with most of this column’s readers, in this case, he eventually performed this test and then richened the jetting at first back to stock on the secondary side and then slightly richer. In both cases the Jeep responded positively to the changes.

He reported the Jeep has never run as strong as it does now, so apparently this cured his problem. He didn’t bother to re-run the acceleration test but it’s clear the results were positive.

We’ve listed the stock Edelbrock main jet and metering rod combinations for the primary and secondary followed by this tuner’s first changes, followed by the final changes that improved the performance. As you can see, there are some significant changes in metering. For most mild street engines on pump gas, making changes beyond three to four jet sizes (roughly 10 percent) on either side of the stock jetting may indicate something may be amiss. This is not true in all cases, but is an indication something is requiring a major change in fuel either lean or rich.

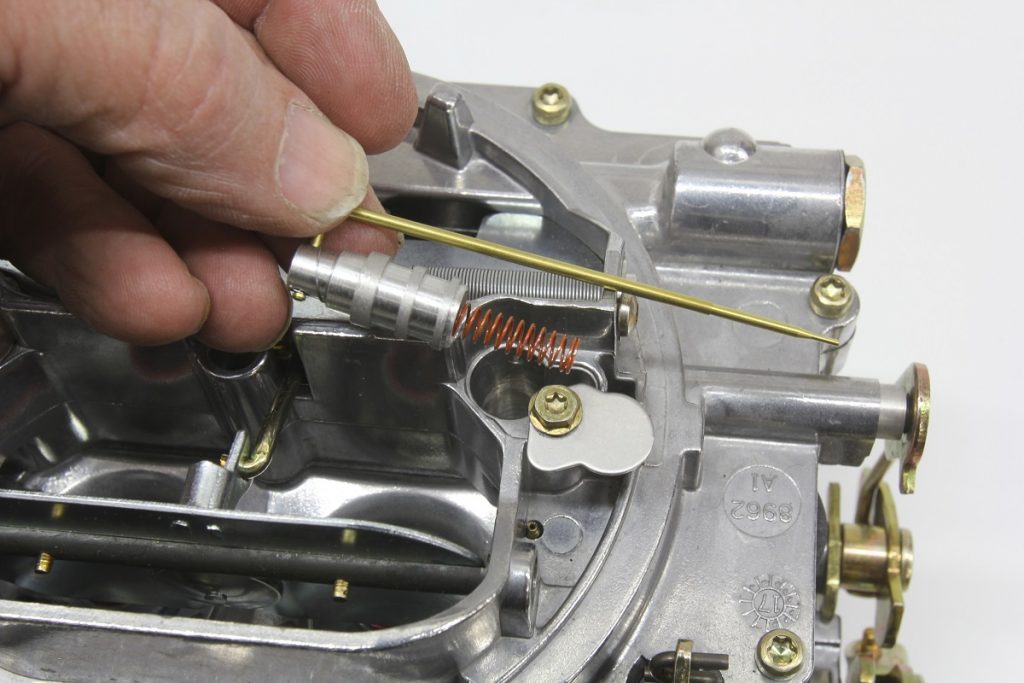

In the Edelbrock tuning chart, the primary metering rod has two dimensions. The first is the large main part of the rod that sits in the jet during light throttle applications. The second number is the power tip. This is always smaller and when at WOT the spring pushes the metering rod out of the jet, leaving the smaller rod diameter to allow more fuel. The total fuel is determined by power tip area subtracted from the flow area of the primary jet.

Since the primary jet is larger than the metering rod it has a much greater effect on jetting. In the first tune, the primary jet is much leaner even though the rods are smaller. Overall, the primary fuel is reduced.

Combined with a much leaner secondary jet, the engine was starved for fuel. As you can see, his final tune is only slightly leaner on the primary side and the engine runs much better.

Hello jeff, I’m running a 1411 , 750 edelbrock carb on a 427 cid SBC. I have been playing around with my jets and rods for the past week. I have .620 ” solid roller with 247 degree duration howards solid roller, 700r4 with a 284 first gear and 373 moser 12 bolt rear in a tubbed 1964 chevelle. Lots of power but I am having trouble fine tuning. I am currently running .104 main jet and metering rods 0.073×0.037 ,(1454) can you dial me in? thanks.

also 10.3 : 1 compression ratio , 112 lobe separation, 235 AFR heads and hurricane intake. The short block engine came from cnc motorsports and I finished the top end myself. A 3200 rpm stall speed converter is also used. thanks

Jeff, I always enjoyed your articles in car craft. They were the most accurate and had the most detailed technical explanations in that publication.

I have a 1966 Ford Thunderbird, 428 FE bored to ~ 460 with, forged crank, rods & pistons, Crane solid Roller cam, roller rockers, smith bros pushrobs, all ARP studs and hardware. Eddelbrock performer heads, Triple-cut, ported and matched to the High-rise tunnel ram sporting two 650 CFM Proform dual pumper Race carbs. No chokes, mechanical secondaries, 8 idle air bleeds. An MSD distributor with AN6 CD unit with mechanical advance only. 3500 RPM Stall converter and a built C6 trans, 3.9 gears in rear end.

I’ve only just recently fired up this beast and have set the initial timing at 12 BTDC. Any guidance going forward to help dial in the carbs without a dyno?? So far, I can’t seem to get it to idle below ~ 2000 RPM. I’m surprised by that. Might be the cam is too aggressive to support a lower idle??

Any suggestions appreciated.

Hey man I just wanted to thank you for sharing such great information with all the motor heads out there. I’m trying to wrap my mind around the tuning chart that came with my Edelbrock 1906 ABS too. I have my grandmother’s Impala which is still relatively new and I turned it into a hot rod with a lunati cam performance header performance 650 carb, streetfire distributor, headers, header cutouts, and twin Flowmaster 40s. I want to get the most out of this carburetor and I don’t understand the tuning chart. When and why would I ever move from point number one? Even if you never reply I want you to know you are very much appreciated

Stan, thanks for the kind words. Tto answer your question – every engine runs a little bit differently and may require less fuel or more fuel to run better. Because the carb company can’t possibly tune for each engine, they design the system slightly rich hoping it will run fine. Engines will run fine slightly rich in the air-fuel ratio. But by trying a slightly different mixture combo, you might find the engine will respond with better throttle response and perhaps a little better power. This is nont limited to air-fuel tuning – it also applies to ignition timing. My suggestion on your carb would be to try slightly weaker power valve spring (assuming you hve an Edelbrock carb – you didn’t mention exactly what you have). This weaker spring will keep the metering rods in the jets longer and the motor might run better – but you won’t know unless you try. Simple one-step-at-a-time experiments will show you which way to go.

Thank you so much Jeff.

I have the edelbrock 1906 AVS2 carb.

It came with the orange spring installed. Perhaps I will try the pink one.

So basically..slowly methodically try different things keeping account of different results?

What is the definition of “cruise mode” or “power mode”?

One more question if you dont mind…IMS are only concerned with idle correct?

Mel

My nephew carb leaks gas from there is it because to much fuel or not enough does he have to change the springs i know it’s an easy fix just trying to help him out

Thank you so much Jeff.

I have the edelbrock 1906 AVS2 carb.

It came with the orange spring installed. Perhaps I will try the pink one.

So basically..slowly methodically try different things keeping account of different results?

What is the definition of “cruise mode” or “power mode”?

One more question if you dont mind…IMS are only concerned with idle correct?

Stan,

Yes – make one change and evaluate. Small changes may not make much of a perceptible change – but may do so over a longer period of time based on changes to the weather. As we approach summer and temp increases, the engine will run better if leaner with warmer weather. Cruise mode would be highway light throttle – running mainly on the idle side of the circuit. I’ve never messed with the idle circuit on an Edelbrock so I don’t ahve any experience there. “Power” could be defined as the point where the primary power valve spring pushes the metering rod upward. Of course, that would include when the secondaries open too. I had a friend who liked to cruise at 80 mph in overdrive taht demanded higher throttle opening and his fuel mileage was terrible – single digits! We changed to a lighter power valve spring and his mileage increased by over 50% – so small changes can make a big differnece! Not sure what you mean by IMS…

I have a edelbrock 1406 jetted 98 front 101 rear .73x.037 rod orange spring runs rich air isle not adjusting had same problem with edelbrock 1407 stock carb check both foe floats off 7/16 and 1 inch drop this is on a 350 with big cam 14 inch of vacuum rpm manifold spacer vortec heads worked for 550 lift plugs are black when reved up puffs black smoke engine runs hard above 3000 rpm but bogs, stalls etc from dead stop can you help?

Hi Jeff.

I have a Edelbrock 1406.

The secondary butterflies won’t close all the way, they

are about 1/4 open. Even when I open the throttle all the way open the butterflies are still 1/4 open.

Your thoughts?

Thank you,

Jay

Jay,

I would first remove the carburetor and see if the secondaries fully close. If so, then either the base gasket or something else in or near teh mounting base is holding the secondaries open. If this does not improve after removing teh carb, then carefully inspect the linkage – it is usually something minor.

Looks like a great site, thank you. have 1 question . have a 1975 motor home 440 engine, Iput a 600 cfm edelbrock on it . main jet is 392/120. i find that the engine is wasting the fuel, excess consumption. what should i try to reduce consumption of fuel as per jet size. thank you in advance.

My nephew leaks from this area is it because to much fuel or need to change the springs its tighten down it’s ok when you start it but when you go the street it flood out and we seen where the fuel come out can you give me any clue is to what going on this is his first hot rod /cruiser

It sounds like you have a piece of dirt or debris in the needle and seat. This will hold the needle open and quickly flood the engine. The needle and seat need to be removed and cleaned. I woul also suggest adding a new fuel filter to prevent this from occuring again.

Hey Jeff, I have a 66 mustang 289 C4 car with only mods are tri y headers, Eld 500cfm carb, Eld performer intake. Car runs great but throttle response could be better. What would you do first change springs, Metering rods? Would like a little more power.

Good info,and I needed it! I have just bolted a 1406 on my 454. Its in a ext cab 1 ton 4l80e. I went to a 600 to try and improve my fuel milage a bit, 10:1 big oval heads, sum-1302 camshaft I don’t remember specs off hand but it idles @ -13. Opened idle circuit a lil bit and it idles fine, stomp it from a stop sign and one time it jumps and goes but sometimes it just lags, cruise is ok but if you roll in to it easy its boggy, go straight to secondaries and it picks up and goes pretty good….worse in the evening when it cool off so I assume lean right? Looked at the chart and decided to try 23 tune, ordered the metering rods and spring assortment also ordered the acc pump and spring from an 850, it will all be here tomarrow. A professional “holley” carb builder stated that a big hungry engine could pull way over a carbs cfm rating thru a smaller carb, is this whats happening with this 600, and why it seems so lean under part throttle? Thanks for any input!

Hi jeff

I installed a 1406 carburator on a small block 350, it is working but I think it is too rich in gas. It probably comes with jets and rods to work at sea level, and I live at an altitude of 7,425 ft . Do you think that I need to change the size of the jets and rods? What would be the right size for this altitud?

Thank you so much

Armando

I have a 1406 that been sitting on a 350 small block in a 57 wagon that I haven’t ran in quite a few years. Finally got back To it. When fuel pump puts fuel to It the fuel starts pouring out of the rectangular hole next to the left side metering rode. The carb has never been on the street. Was rebuilt when the engine was built . Only ran it once about 5 years ago. Ran very good. I assume the carb Is varnished up in side. When fuel is coming out the left hole next To the metering rod whats going on. And what’s the easiest way to fix it. Thank s

I bought a 1970 GMC with a stroked 350 and I’m attempting to figure out the best jet /rod combination for the Edelbrock 1406 that’s on it. I read that you want to shrink the jet size by one size for every 1500′ rise in elevation. This truck is going to be driven between Colorado and Texas, so I was shooting for around 3500′ elevation as an average. Based on what I’ve read and a guess, I was considering a .092 primary jet with a 070 x 047 rod and a .089 secondary jet. I’m pretty green at doing this sort of stuff, thus I felt it was best to consult a professional. Please give me your thoughts on running this combination as a solution to reaching my objective. Thank you,

Hi Jeff

So I have a 85 GMC k1500 with a stock goodwrench 350 motor. The only thing I’ve done is remove the old intake and replace it with a performer edelbrock, and 1406 carburetor with electric choke. I live at 4k feet elevation and only use it as a cruiser truck. It’s getting horrible fuel economy and was wondering what primary jets and secondary you would run to slow down fuel consumption a bit.

I appreciate you helping me out.

Scott

Have a dual quad air gap intake with Webers set up on a 2006 5.7 Hemi that is extremely fat to the point of black paste at end of tail pipes. any idea of a what a good jetting starting point would be? I bought the car with this set up so I am limited to information. Any info would be greatly appreciated. Thanks, Ted