Never before have so many enjoyed so much for so little.

Take a look around. We are smack dab in the middle of the second major Muscle Car era, and this one has taken the power levels to new heights.

I love a DZ302, Boss 429, or Hemi Cuda as much as the next guy, but line one of these muscle motors up against its modern counterpart and you quickly realize how fast things are today.

This modern muscle has plenty of carryover for average enthusiasts, as the LS, Hemis, and Coyotes of the world eventually find their way into wrecking yards.

It’s amazing that you can grab a used LS (as well as a Gen. III Hemi or Coyote), high mileage at that, add a cam, springs and boost, and make four-digit power.

The icing on the cake is that this four-digit power level can also be driven on the street, and get good fuel mileage to boot. Much of the credit goes to the advent of modern fuel injection, but the influx of affordable boost is responsible as well.

To illustrate just how easy we have it these days, and to put one of the Summit S475 turbos [to the test, we decided to take the “easy” route with a 4.8L LR4.

Though our test mule was already fortified with a few mods, this can easily be duplicated with a junkyard version with equal success. That we already had a suitable 4.8L ready to rock, made things that much easier for us.

The 4.8L we’re testing started out as a high-mileage wrecking rat, but some poor choices on our part meant it had to get a fresh set of pistons a few years back. A quick bore (.010) and a new set of forged slugs took care of the damage.

We installed a set of JE forged pistons that featured 7-cc domes to help with our static compression when running naturally aspirated applications.

It also worked under boost, albeit with proper timing, intercooling, and fuel. The forged slugs were swung on a set of well-used, Gen 4 rods, because why not step up from those weak Gen 3 rods?

Never mind that we have made hundreds of pulls on them over 1,000 horsepower, but off they came! The rest of the bottom end included a stock block and crank, along with Fel Pro MLS head gaskets and ARP head studs.

To help this test motor make some power, we upgraded two things — the cam and valve springs.

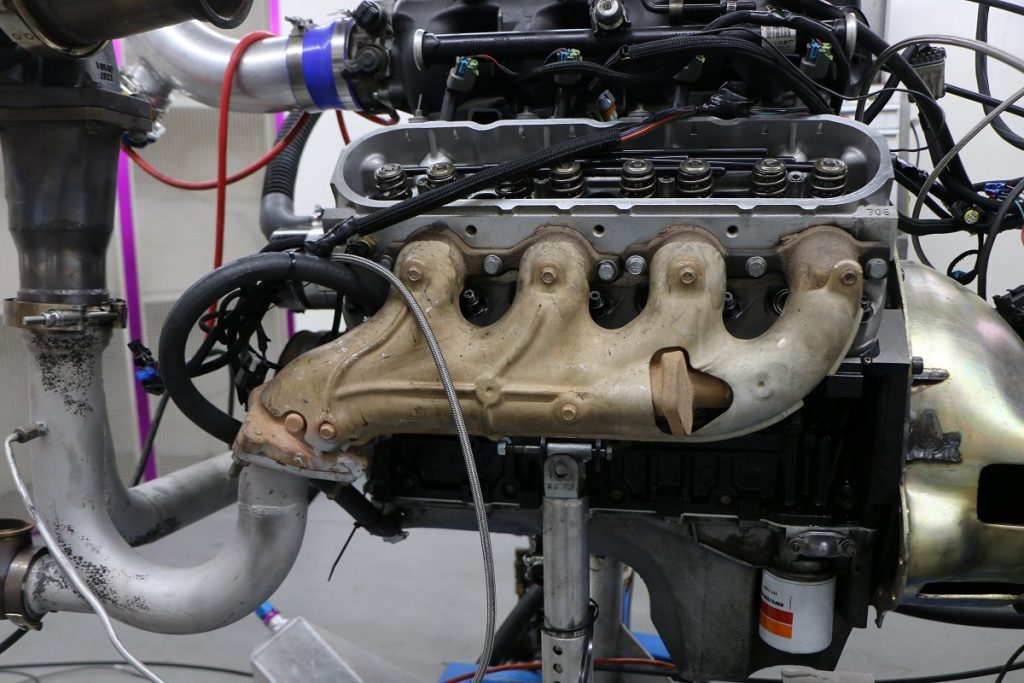

The stock LR4 cam had long since been swapped out in favor of a Stage 2 turbo cam from Brian Tooley Racing. The cam was combined with a set of 26918 valve springs from COMP Cams. This allowed the 4.8L to not only rev, but actually make decent power.

Remember, the gains offered NA can be multiplied under boost, so a little bump in power becomes much bigger under boost. That’s why we go to the trouble of camming the LS in the first place. The cam and springs were combined with more stock stuff, including the factory 706 heads and truck intake. Sure, there are sexier components to install on the 4.8L (like TFS 205 heads and a Fast LSXR intake), but the stock stuff worked just fine, and it came with the motor when we plucked it from the yard!

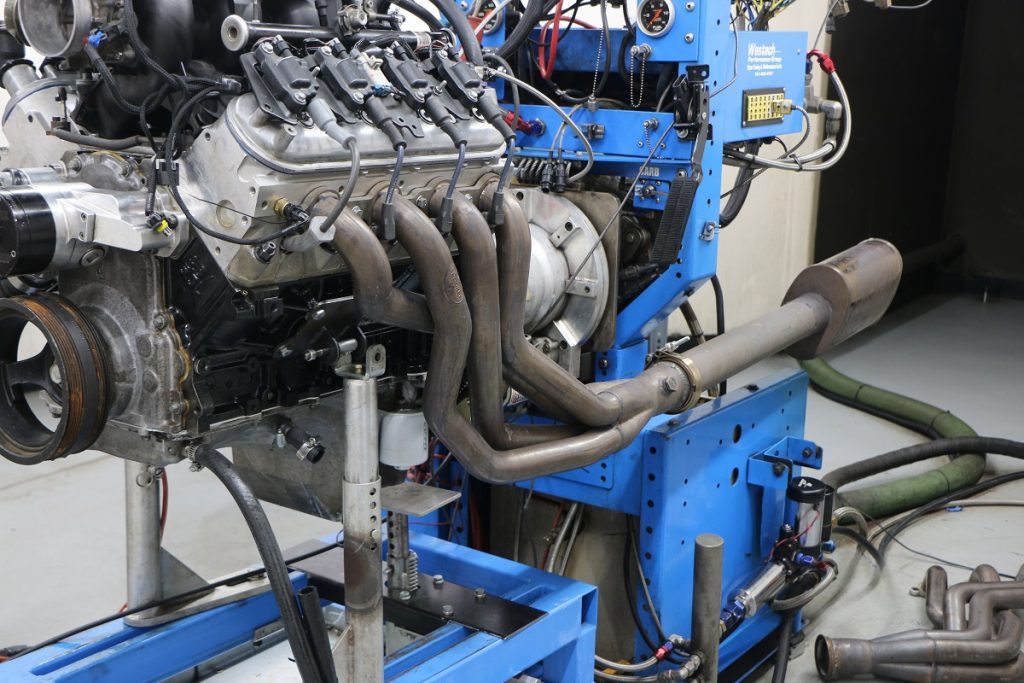

Finishing touches included a set of 80-pound ACCEL injectors, Hooker long-tube headers, and a Holley HP management system.

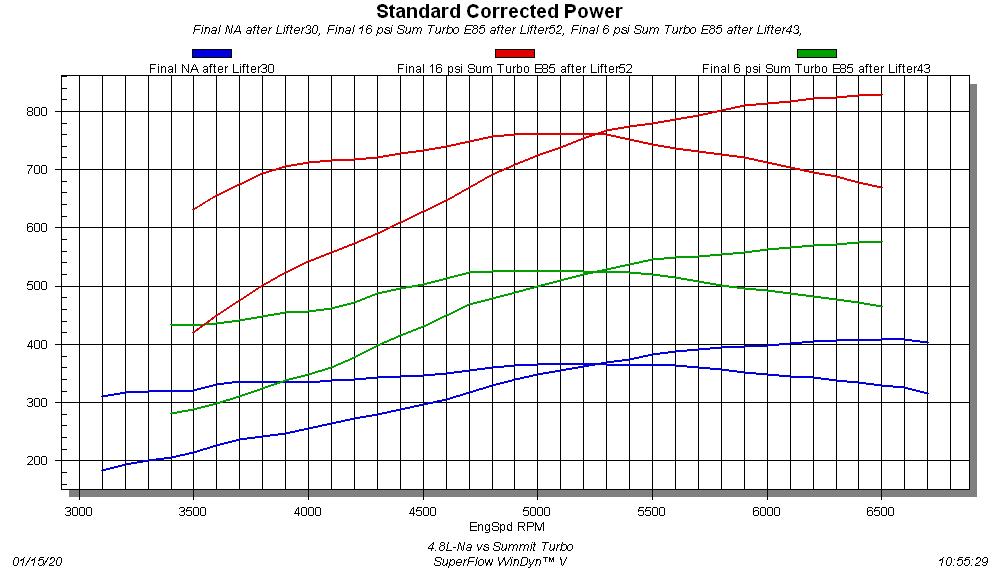

Run in this trim on the dyno, the little 4.8L produced peak numbers of 409 hp at 6,600 rpm and 367 ft.-lbs. of torque. Now it was time for boost!

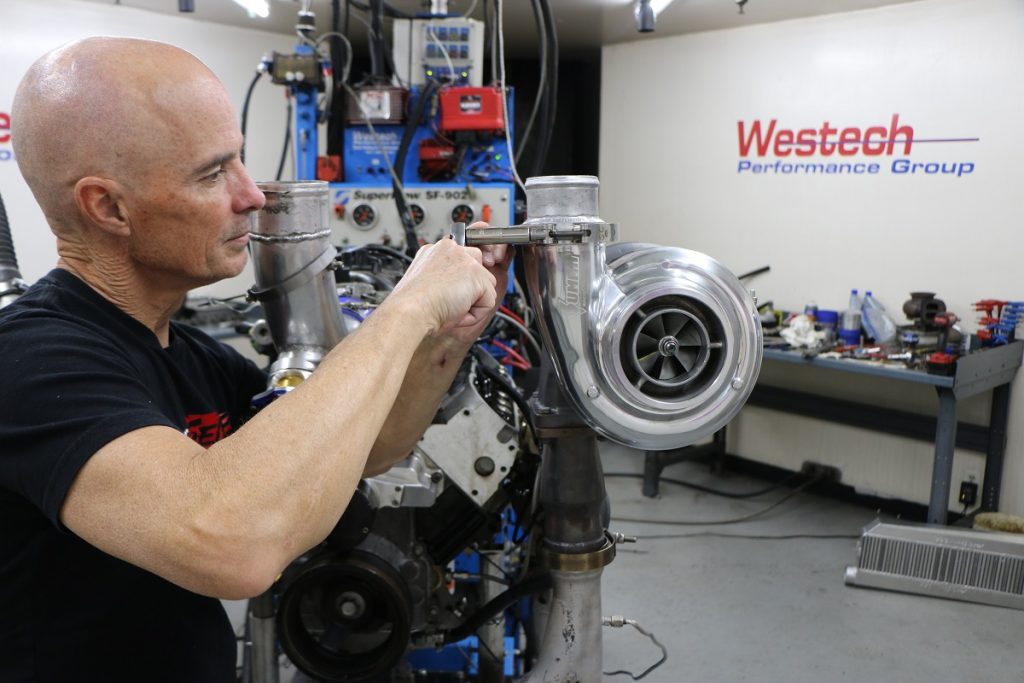

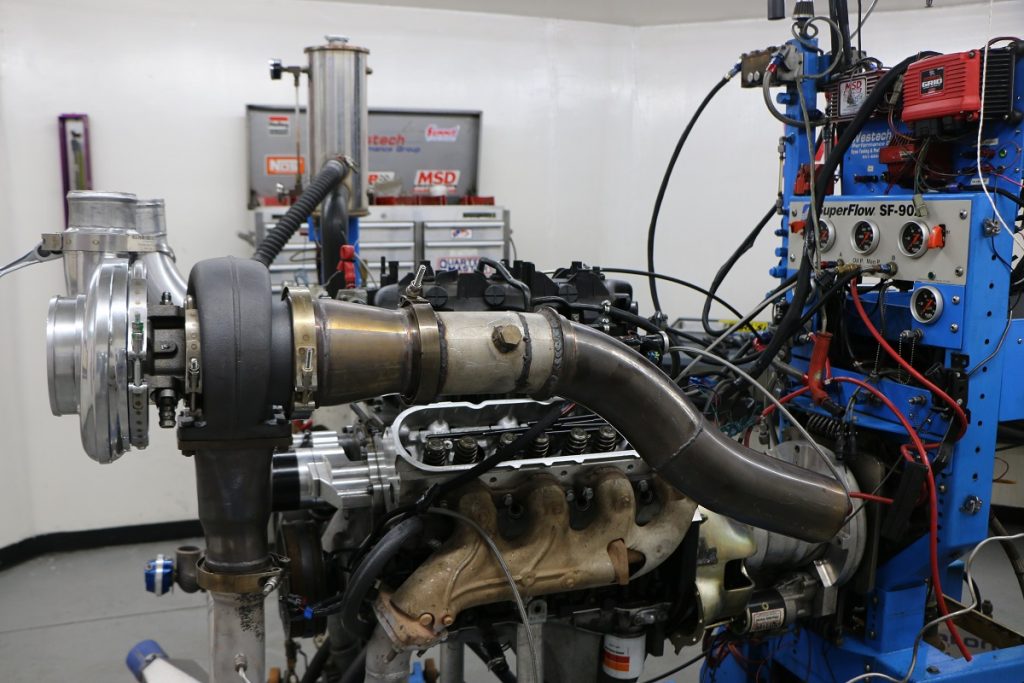

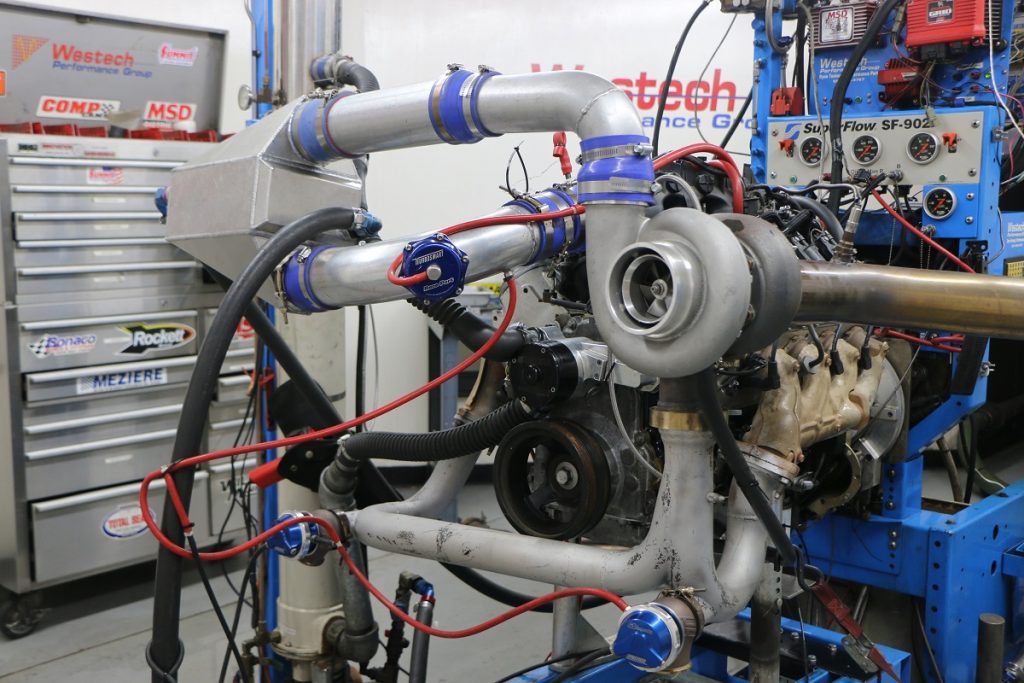

Boost was supplied by the S475 turbo from Summit Racing.

The twin-scroll, T6 turbo featured a 75-mm compressor (inducer) and an 88-mm turbine (exducer). The turbo also featured a 1.32-A/R ratio turbine housing and the ability to support near 1,000 hp on the right application.

We were not looking to push our test motor there, but it is always nice to know there was a little extra after you get tired of running just 10, 12 or 14 psi (pick your number — you will crank up the boost-they all do!). The turbo was installed with a custom turbo kit which featured a truck manifold, a custom Y-pipe, and a pair of Turbo Smart Gen 5 waste gates.

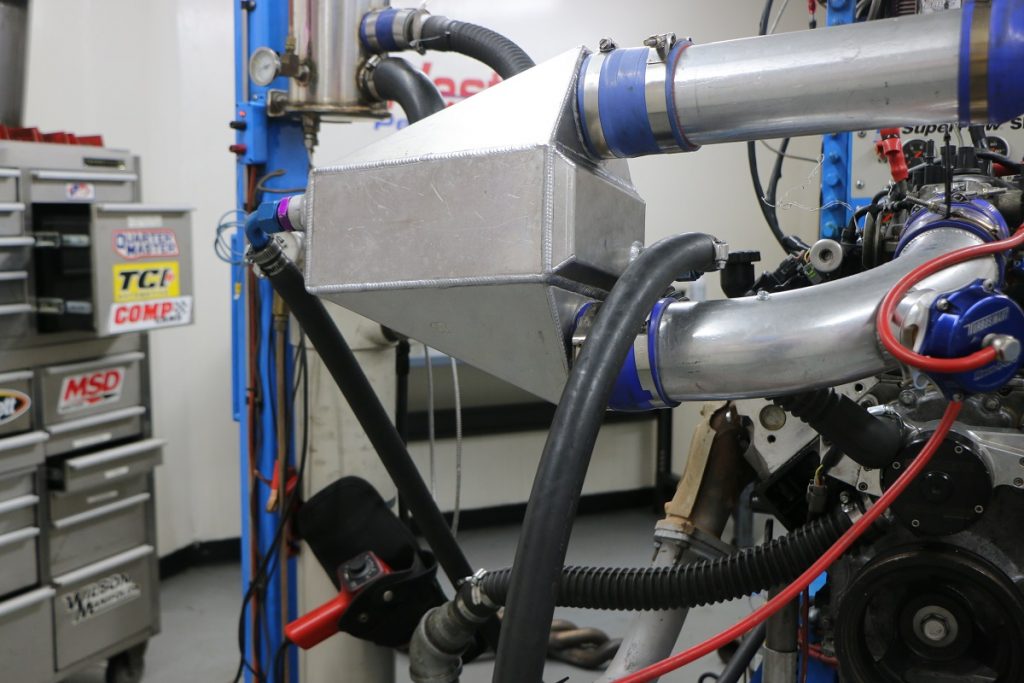

Turbo Smart also supplied the Race-Port BOV, though they constantly yell at me to upgrade to the latest version. What can I say — I’m OG BOV! Boost from the Summit turbo was supplied through an air-to-water intercooler from ProCharger.

Run first at 7 psi and a soft tune on pump E85 (our low-buck race fuel of choice), the turbo 4.8L produced 576 hp and 525 ft.-lbs. of torque.

After stepping up to a solid 16 psi, the power needle showed 829 hp and 761 ft.-lbs. of torque. Take a look at the power curves in the supplied graphs and you can see the power outputs at different boost levels. You can also see that the turbo was ready to support even more power, but how can you complain about an 800-hp 4.8L?

Especially when it was so easy.

…

Another well done technical article by Richard Holdener. It’s times like this that I also feel grateful to On All Cylinders and Summit Racing for making such real world information available to all Motorsports enthusiasts.

We truly are enjoying the second round of factory supported horsepower wars. Depending on how a person sees it, I was fortunate enough to be heavily involved in the first round of escalating factory power numbers during the sixties into the early seventies. The only negative aspect is that I’m old enough to share those glory days with my younger friends. Oh well, no worries because with a little luck and common sense the young gear heads will be around to share their experiences with factory muscle cars way back in the days of 2020 ! And with the amazing performance levels on and off the track in 2020, it’s a story of monumental proportions and worth remembering.

As Richard stated, I also dig the first generation of factory performance cars but with Fords at the top of my list for a pretty good reason. In 1971 at age 17, I was fortunate to own my first Mustang Mach 1 out of three total over the years. It was a mint ‘69 with the 428 CJ, factory ram air and C-6 automatic. It only had 19,000 pampered miles on it when I paid $1850 to the original owner. Street racing was popular simply because there wasn’t any decent drag strips on the east said of Atlanta. The one strip in the area was known to be unsafe at any speed. Most folks have heard about Yellow River drag-strip. After the horrible nightmare occurred, it was closed permanently but the streets are still open.

That first Cobra Jet had massive amounts of tire shredding torque at any speed below 60 mph. It definitely left a lasting impression on my young mind for many decades after it was long gone. I was convinced that nothing new coming out of Detroit could even come close in performance. MAN WAS I WRONG ! The veil of performance ignorance was lifted from my head in the fall of 2003.

A woman that I worked with showed up one day in her 2003 MUSTANG COBRA. She knew about my involvement with cars and wanted to know if I would do the routine maintenance on her Cobra. She tossed me the keys to evaluate her car and said to keep it all afternoon if I wanted to. Naturally I was curious about how well a SUPERCHARGED , DOHC, 32 valve 4.6 liter Ford would perform. My mind was still convinced that there was no substitute for cubic inches. 428 inches of early Cobra Jet to be more specific. After all, just how bad ass could 281 cubic inches really be. Even with a toy supercharger on top.

I fired it up for the test drive without the owner coming along to “supervise” my driving. It sounded tame enough as I rowed through the 6-speed while getting far away enough from the owner before going WOT for test purposes . On the first safe stretch of road, I didn’t hammer it from a stop but simply got on it from a slow roll in first. I loved what came next. Both rear tires roasted immediately as the supercharger SCREAMED its awesome song. First gear was hopeless for traction so I figured a power shift into second would calm down the smoking tires. WRONG AGAIN because the tach shot to the moon and was bumping the rev limiter almost instantly. I was pleasantly surprised at how straight the car would go with tires blazing. My old Cobra Jet would use all lanes available under the same situation. It was a handful but the’03 Cobra has a nice balanced feeling as the suspension worked well to keep the car manageable under duress.

My test drive was 3 hours long and I pushed the Cobra hard and it never felt like it had reached its limits. Traction was limited in the first three gears on asphalt city streets. I took it out on interstate I-285 for room to check out the top end speed. It was a little too crowded for an extended run but 145 came quickly. That’s where I also got to check out the aftermarket brakes and how well they worked during urgent high speed situations. They performed well every time. The Cobra cornered like it was on rails which helps provide an overall confidence in the cars capacity to handle almost anything that comes its way.

At this point there’s no way possible to make a long story short. But my long winded point is that an old dog can learn new tricks. As great as the original muscle/pony cars are, they definitely are limited when compared to what’s going on now. Advanced automotive technologies have changed everything for the better on every level of performance. Each one of Detroit’s big 3 car manufacturers has at least one extreme example that with a little race fuel in the tank and a proper tune, a decent set of tires for traction and a track surface that’s been optimized, you can buy the car of your dreams from a local dealer that comes backed by a factory warranty that will power you down the quarter mile with a single digit time slip waiting for you as you drive back to the pits with the AC blasting and subwoofer thumping.

In 1964, if you were a dedicated Ford drag racer at the top of your game and your closest friends also happened to be the top level brass at FoMoCo, you just might have had a shot at taking possession of one (or more) of the 100 examples built of the specially prepared lightweight 1964 Fairlanes featuring the most powerful naturally aspirated AND Super Stock legal engines available at the time, the legendary 427 “High Riser” with 8-V (Venturi) Induction system consisting of dual Holley 4-V carburetors on an alloy intake manifold. The drag racers worthy of Ford sponsorship could purchase these THUNDERBOLT Fairlanes for the legal sum of $1. That’s one dollar and not a typographical mistake.

Aside from the blown nitromethane thirsty fuelers, these Thunderbolts along with Drag Race only speciality builds from Chrysler and GM would pack the grandstands with rabid fans screaming to see a mind blowing E.T. that was generally in the…..10 SECOND RANGE……. Cars built on the cutting edge of technology BACK THEN. If you’ve bothered to read this insane rambling up to this point, you are probably thinking what’s the point. Your daily driver is good for 9’s all day long. Why does this even matter ???

If you have been around professional competitors at the track or worked in a Pro Shop like many of us have done over the past 40 or 50 years, then you could clearly see how technology has changed the game in ways that are almost impossible to comprehend because of the huge advances in recent years.

Richard Holdener has touched on several key factors about the vast possibilities for real performance that are waiting as close as your local parts recycling center. The modern engine cores is where a lot of it starts. Through technology the foundries are now producing items like blocks, rotating assemblies, heads and more that are stronger with more precise machining and at a lower cost than ever before. This is why it’s entirely possible to select the core you need and with minimal additional parts cost, bolt on a salvaged turbo charger and apply common sense along with a good tune then PRESTO, your 800 horsepower junkyard gem is ready to rock your project vehicle.

Mechanical Marvels also advance thanks to the flow of technical evolution. Much in the same way that living carbon based units are constantly evolving.

That big lump of technically advanced metallurgy doesn’t care anything about brand loyalty. The modern foundry used technology to produce superior elongated nodular patterns. No matter if the finished product gets painted Ford Blue or Chevy Orange, it’s much better than the original part made 30 years ago.

And the beat goes on…….

That was an absolute blessing to read. Thank you for sharing somewhere that young car enthusiast, like me, can stumble upon it and be inspired to continue being passionate about cars.

I also think it’s great that OAC allows the readers (and I know you’re out there. I heard that pin you dropped) the opportunity to add your $0.02 worth of opinions and/or comments in response to the article. So far the toll collector has only two pennies to show for this well documented effort by Mr.Holdener. I’m absolutely certain that each and every one of you guys has paid a visit to your local salvage yard and spotted enough treasure to build that AA/FC or Top Fueler you’ve always wanted. I’m prepared to offer a penny for each comment posted. This offer expires at midnight left coast time. Act fast because the roaring silence in here is deafening.

And as always… the beat goes on……

These turbo test are so exciting. And I will build my own, one day.

At the moment, I’m keeping my car prepped for bracket racing, with a big shot of nitrous for an occasional street race. But I always love it when a nitrous car noses past a turbo car at the track. I love it.

I would love to see some research about the consistency of a turbo car. My math says it would probably be horrible, and the bracket race game is faster and more consistent than ever before. Maybe next year I will stuff a turbo setup under the hood. But for now, I’m just thankful to have my car making passes.

curious how long a motor with this power level would last as a DD?

plenty of vehicles on the forums claiming over 60k with no issues

I love reading these posts because they give me hope that im going in the right direction…. im building a pair of twin turbo lq9’s that are going in a 42 foot fountain boat, im out to disprove these marine engine builders telling myself and everyone else you need a motor that costs $30k to run and last a reasonable amount of time in a boat!!

What is a safe timing table for this type of setup I’m running a 4.8 same turbo and cam but carbureted and there’s no info any where on optimal timing curves

I’ve been thinking about a single turbo set up for my daily driver. It’s a 2002 Chevy 2500hd crew cab long bed 4×4. It currently has the 6.0 with 4L80E and 4.10 axle gearing. My thought was to freshen up a 4.8 with a single turbo built for good low end torque for towing a 25 foot fifth wheel camp trailer but also with an eye on unloaded fuel economy. Is this a viable set up? I was thinking possibly 450 ft pounds of torque around 3500 rpm and horsepower around 400. Or should I just keep the 6.0 and freshen it up when it gets tired. I’m looking for a combination I can install and not have to touch it for at least 150,000 miles with towing and mph in mmind. It as 275,000 miles on it but doesn’t seem tired yet. It does burn a little oil. But runs circles around my old 454. What are your thoughts

How much do you think this would all cost? I already have a 4.3L ls I need just a ballpark of how much this will all cost if I install it all myself

Epic, write more articles. I loved it but that is obvious.

Wanted to know if you also do tunes , wanted a tune for a 4.8 with 96lb snake eaters ,summit stage 2 turbo cam and vsr 75mm 87×82 T4 1.10 A/R stock 862 heads 0411 dbc…..was looking in the region of 825 whp , its a 6 speed car at 2700lbs and looking to do 9.5 q.mile times on E85 and snow stg1 meth kit .

I got a Gen 3 lr4 4.8 I got twin turbos and a stag 3 sloppy cam is that cam to big for my 4.8