I’d like to build a Chevy 400 to drop in my short box pickup. The goal is a fun street truck, no track time, more likely to hit the highway for a weekend trip and be able to have great acceleration from a stop. I’ve got a block and I’m trying to sort through the steam hole issue when it comes to heads. Seems there are plenty of folks in both camps: drill vs. don’t bother drilling.

Can you shed light on that debate, and can you suggest any Chevy heads (casting numbers) that would be respectable for this engine or should I just count on buying aluminum heads? Also, I have yet to find anything that provides a depth for the holes that would be drilled in the heads. Are there any good illustrations out there? Thanks in advance for any help you can provide.

K.E.

There are a ton of options for cylinder heads so let’s start with that and then we’ll offer some insight into drilling for steam holes.

Picking Cylinder Heads for a Chevy 400

Much depends on your budget, so let’s start with the least expensive head as the iron Vortec version. We’ve written extensively about Vortec Heads in other tech questions so we won’t get into the details other than to say that with a 64cc chamber, you will need a dished piston to keep the compression reasonable at 10.5:1, which will require premium fuel. In this case, you’ll need a dished piston with at least a 13cc dish. A larger 20cc dish will bring the compression down even further to 9.8:1, which would probably be better. More compression will help with a snappier throttle but you have to be careful with cam timing not to go too short in duration.

Since you mentioned aftermarket heads, there are dozens of options. But I would shoot for a port volume of 195 to 210cc to keep the velocity up (which is what you want at low engine speeds to create torque).

Trick Flow Specialties offers an excellent 195cc intake port aluminum small block head with 72cc chambers that, with a 10cc dish piston, would produce 10:1 compression—making it just about ideal. This Trick Flow head is part of their Super 23 degree head series and these heads all flow decently.

But perhaps more importantly, they are affordable. Check out the part number in the chart below for a link to the current price.

Drilling Steam Holes in a Cylinder Head

As for the steam hole question, there are multiple suggestions on how to drill the holes and you should consult the manufacturer of the actual head you will use in order to be sure you are drilling correctly. For example, it appears that Trick Flow will not warranty a head if the steam holes are drilled.

Having stated that, the general consensus is to use the proper 400 style head gaskets with steam holes and use them as a pattern to place the holes in the correct position. It appears a set of Fel-Pro 1014 head gaskets offer these holes and are only 0.039-inch thick.

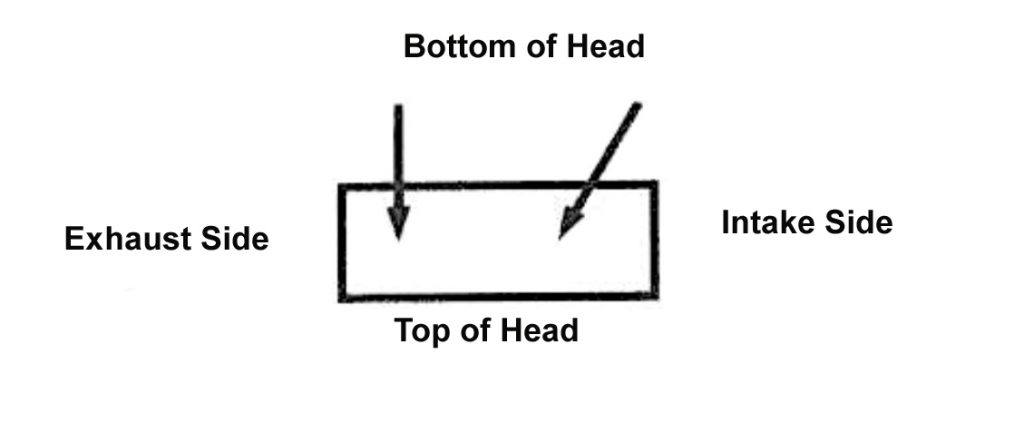

We’ve also included a simple illustration that shows (at least for most heads) how to drill the holes. With the head upside down on the bench (deck surface facing up), use a head gasket to position the holes in the heads. The holes nearest the exhaust side of the head can be drilled straight into the water jacket. You should hit the coolant passage at roughly 1 inch deep. According to Airflow Research, the outboard holes will require slightly more depth—around 2 inches in order to hit the water jacket. This depth will be different for heads from other manufacturers.

For the steam holes near the intake side of the head, these will need to be drilled at approximately a 45 degree angle in order to intersect the water jacket. It would be best to start drilling straight for roughly 1/16-inch and then angle the drill at the 45-degree angle to finish drilling. This will make the drilling process easier. Use a 3/32-inch drill bit for both sets of holes.

The hole…err…whole idea is to allow a vent from the deck surface of the 400 block to prevent a steam pocket from forming in the block. Of course, double check all your dimensions before you drill, but we’ve done this process before on several 400 street engines and never encountered a problem.

A stout little 400 in your pickup is likely to be lots of fun!

Ask Away! Cylinder Heads for a 400-Equipped Chevy Truck

| Part Number | Description |

|---|---|

| TFS-30410013-M72 | Trick Flow Super 23 195 Cylinder Heads for Small Block Chevy |

| FEL-1014 | Fel-Pro Performance Head Gaskets for 4.155" Bore, 0.039" Thick |

That’s the main reason I stay with MOPAR,you don’t have these problems. To me that is a designers flaw.

There is a article .Titled the impersonator. 400 with vortex heads that made like 500ft lbs of torque

Thats a sweet trick engine.

I have a stock 400sbc in my 1970 Monte Carlo. I am rebuilding the entire engine and have decided not to buy aftermarket heads and then drill steam holes. One slip and it’s over. So, I purchased a 68 4 bolt 350 block and will get that squared away and then install the choice of heads with a Isky cam and Edelbrock setup finished off with hooker headers. I will most likely be pumping out about 450 horses when done coupled with a nice Turbo 350 street/strip B&M and the original 12 bolt rear end with my installation of 373’s. It will eat up just about most Mopar’s and that is my goal. Plus, the 70 Chevy, whether a Chevelle, Camaro, El Camino or Monte was much better looking and classier than any Mopar!

I have a 350 small block. Rebuilt with a brodx top end kit. BRO9991010. HEADS INTAKE 2.02 intake valve 1.60 exhaust. And cam .490 intake and exhaust. So it runs great timed carb set. But i still kept my 650cfm carb. So when i punch it it goes but it lags power it wont even smoke the tires. Im thinking my carb is to small. Any recommend size carb i should get for this build. Cause it should have way more balls than what its putting out. But it still drives nice in my 1980 olds 442. Just want to smoke other cars but all i can do is shake my head and watch them take off like a bat out of hell.

Definitely under carbureted. I always had 750 on my 350s and 850 to 950 on my 406s. 650 is perfect for your Ford of any size because they don’t make any power anyway

The carbs not your problem. The high rear ratio and stock torque converter with a stall speed that is not much above idle is the reason your car is sluggish and won’t burn rubber. Try a ratio that’s about 3.50:1 or lower and a converter with a stall speed of at least 2500 to 2800 rpms.

You might try a Holley double pumper 650 cfm.

Check the gear ratio in the differential. It may need something in the 3.42 or 3.73.

If you’re running an automatic transmission, you may need to run a torque converter with a higher stall speed.

The factory didn’t drill those holes at an angle so why do you

Agree, what an unneccessary and bizarre thing to do.

My question,(not answered) was ; do you have to drill any holes in aluminum heads when used on early 350 block with by pass cooling design. I’m told most aluminum heads are usually not drilled . I bought them on eBay. I installed them without checking and it’s hard to keep temperature below 215 even in winter.I have a 3 row radiator with dual 16” cooling fans that are shrouded to the radiator. I’m not referring to the steam holes needed drilled for 400 block.

400 block require the holes drilled for after market heads for sure .